Hydrophobic precipitated silica for defoamer formulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

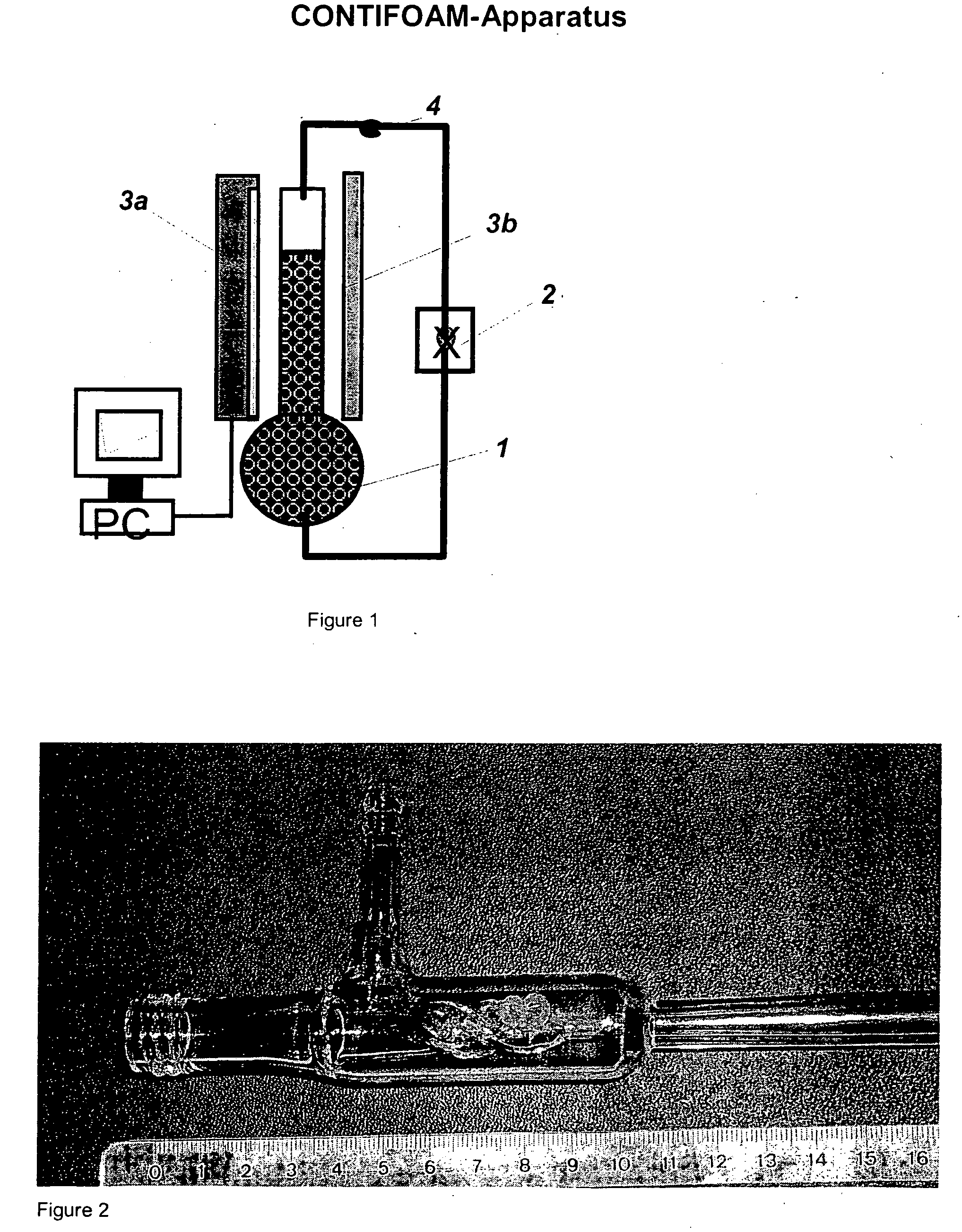

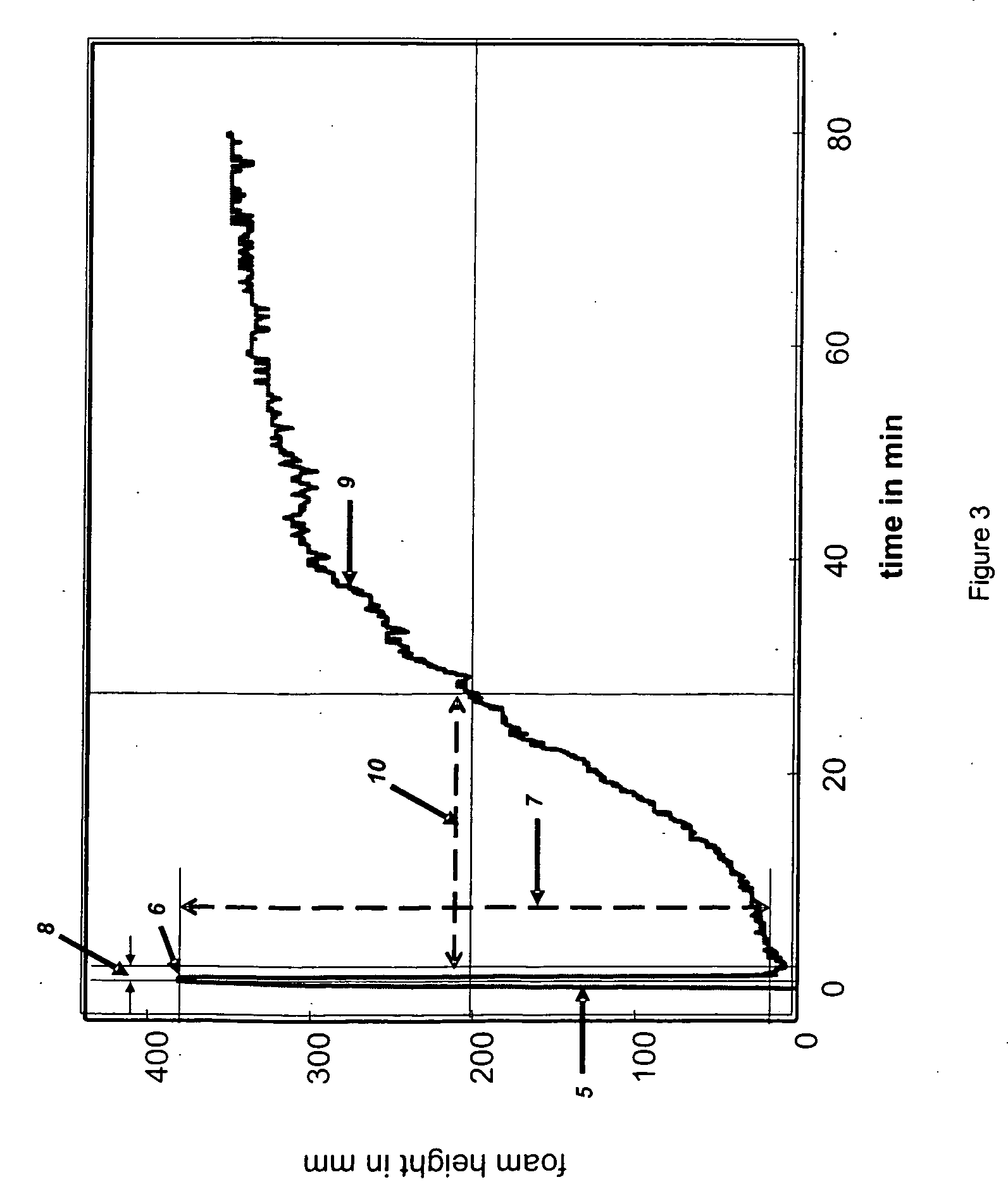

Method used

Image

Examples

example 1

[0227] 63 l of deionized water were charged to an 80 l precipitating vessel and heated to 88° C. Added to this initial charge were waterglass (modulus=3.5; density=1.343 g / ml) at a metering rate of 6.5 l / h and sulfuric acid (concentration=7.167 mol / l) with a metering rate of 1.56 l / h, metering taking place so as to maintain a pH of 8.0-8.5 (measured on a sample with a temperature of 60° C.). After 105 minutes the metered feeds are ended. Subsequently the precipitation suspension was acidified to a pH of 3.5 with sulfuric acid (concentration=7.167 mol / l), with the same metering rate as before, and the suspension was then aftertreated in a drying oven at 50° C. for a period of 12 h.

[0228] The suspension was filtered and washed sufficiently with deionized water. The resulting solids content of the filtercake is 15-17%.

[0229] With deionized water introduced initially, and with gentle stirring, the filtercake is liquefied so as to give a silica suspension with a solids content of 6-11%...

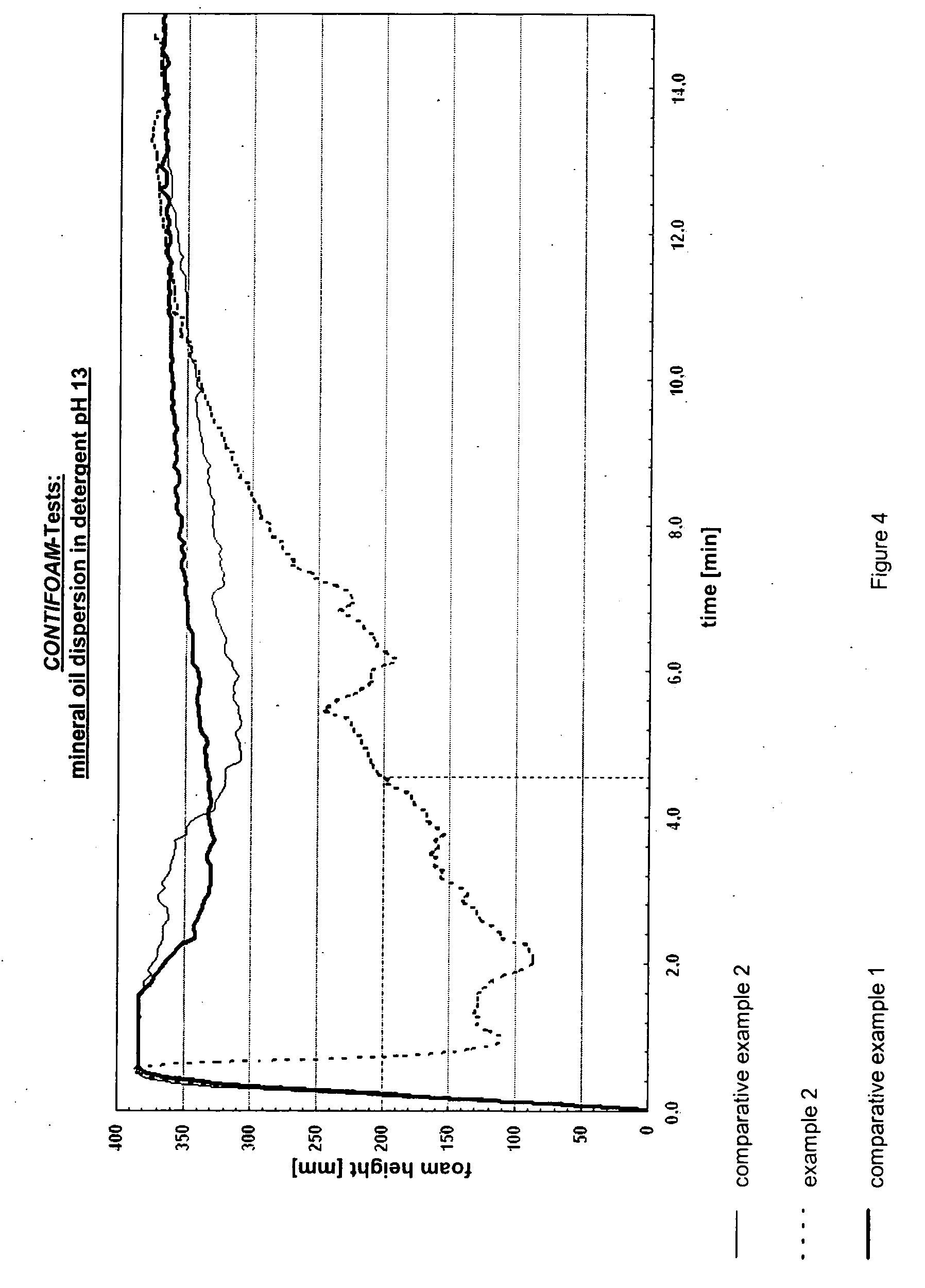

example 2

[0272] Both a mineral oil dispersion and a silicone oil dispersion were produced from the product from example 1 and were investigated for defoaming action.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com