Device for generating a laser light beam

a laser light and laser light technology, applied in the direction of lasers, laser construction details, instruments, etc., can solve the problems of high labor intensity, difficult for users to individually compose laser light beams comprising several laser lines of individual laser light sources, and inability to train personnel, etc., to achieve high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

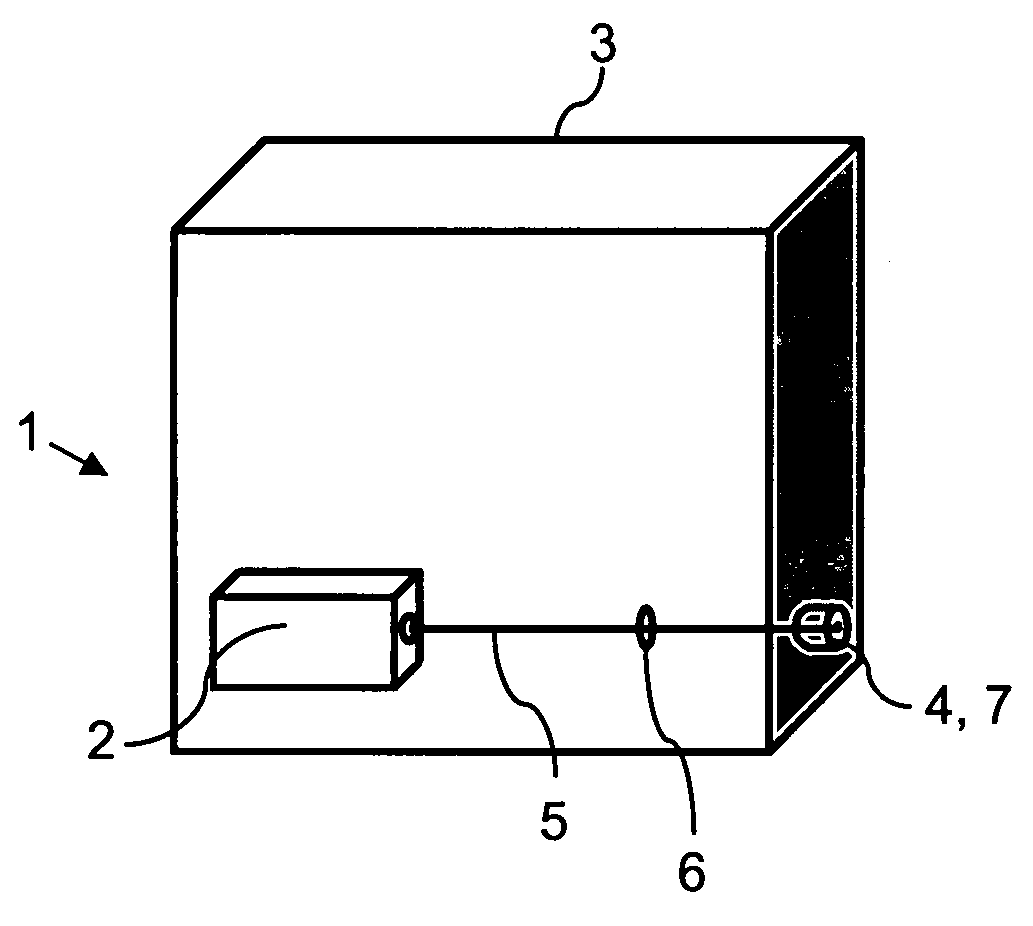

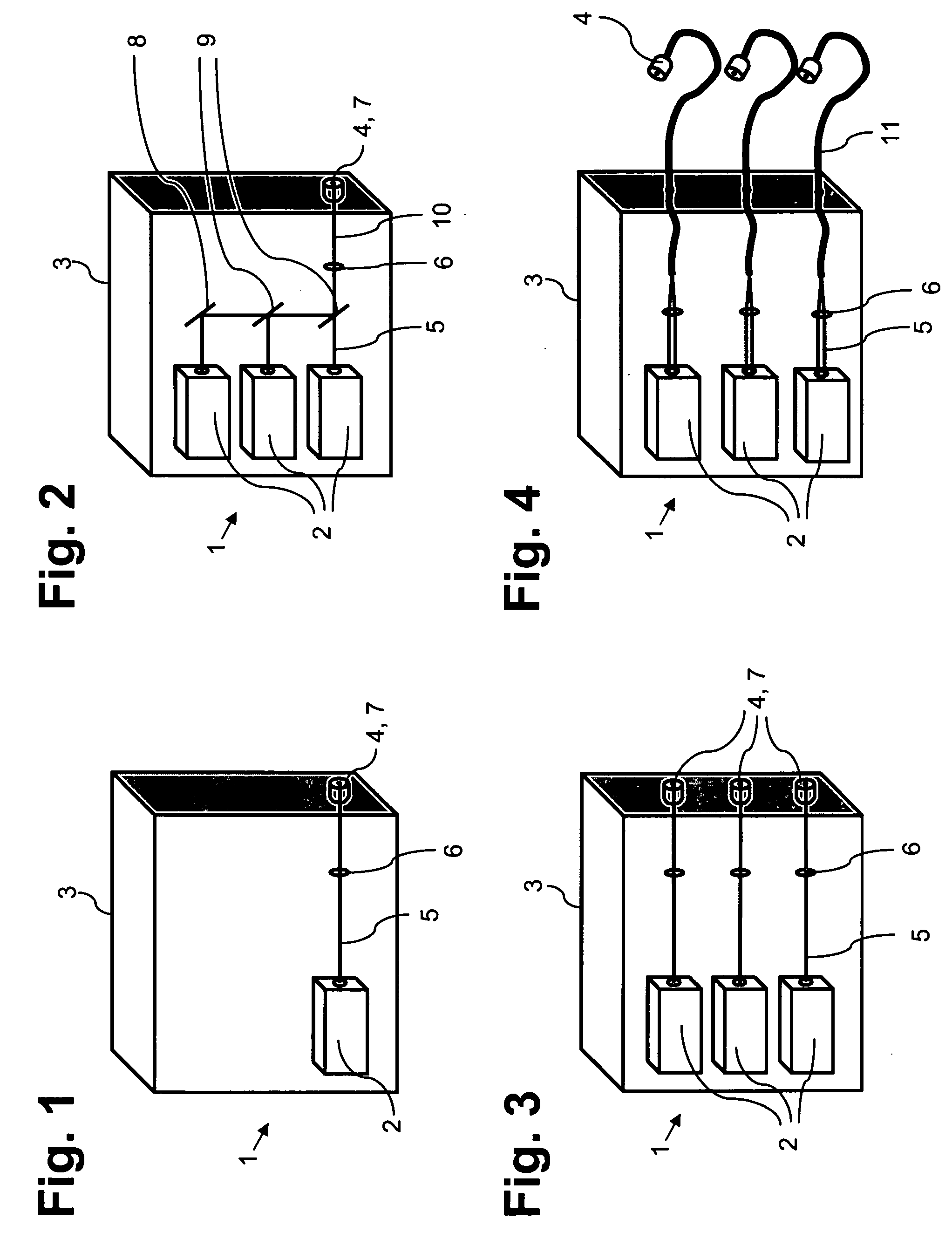

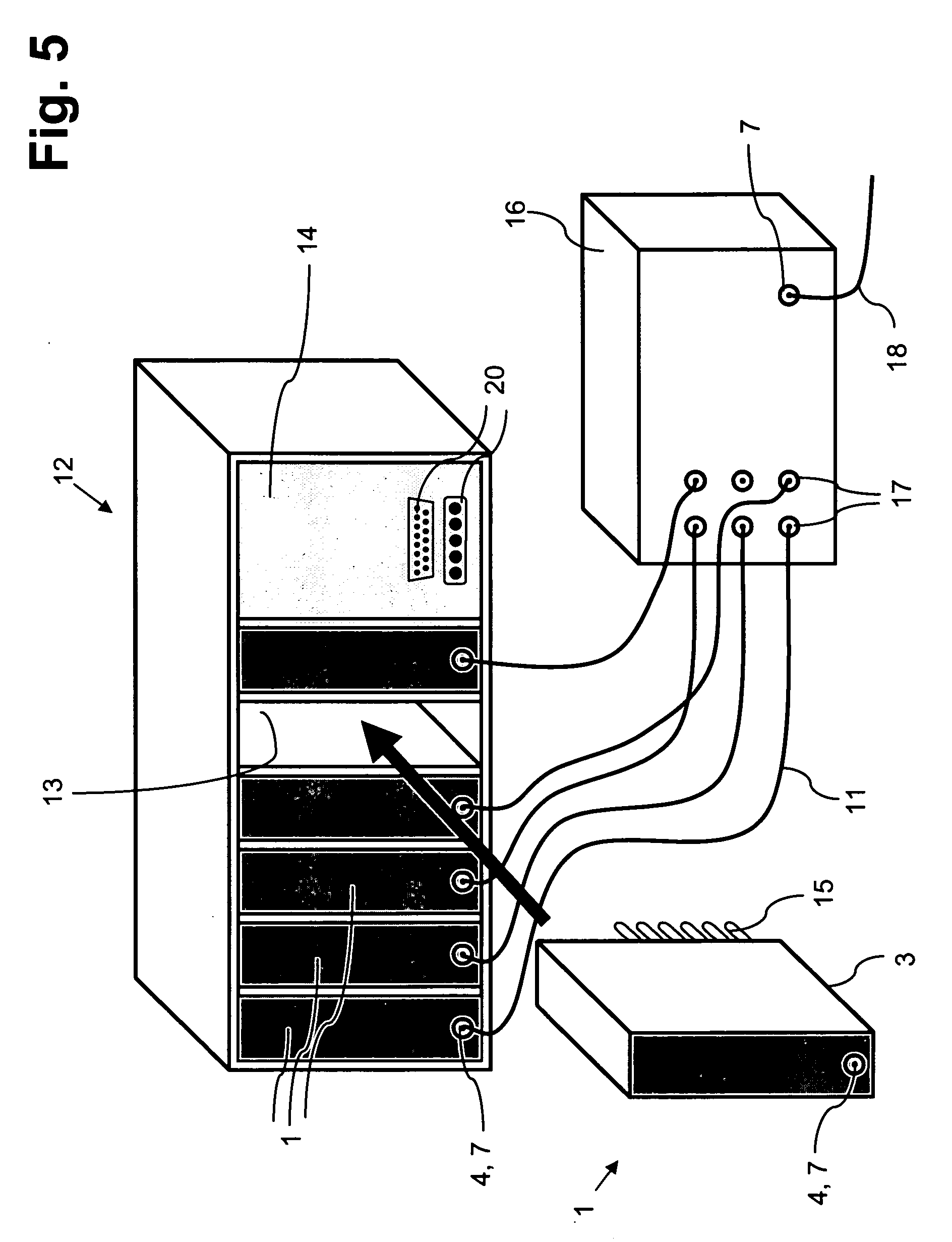

[0017] In a preferred embodiment, there is a docking station with slots into which the individual modules are inserted or slid, whereby the modules can be arranged next to each other and / or above each other inside the docking station. For special applications, the docking station could also be configured with just one slot that accommodates one single module.

[0018] The module could have a housing that then defines the module dimensions which are advantageously adapted to the size of the slots. With an eye towards achieving high flexibility, each individual module could be encapsulated in such a way that it forms an opto-mechanical unit which, in a simple manner, can be mechanically inserted or slid into one of the slots of the docking station.

[0019] Each module could have its own power / control unit integrated into the module. In order to attain a cost reduction as well as a low-maintenance design, however, preference is given to a central power / control unit that can be brought int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com