Four valves per cylinder engine head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

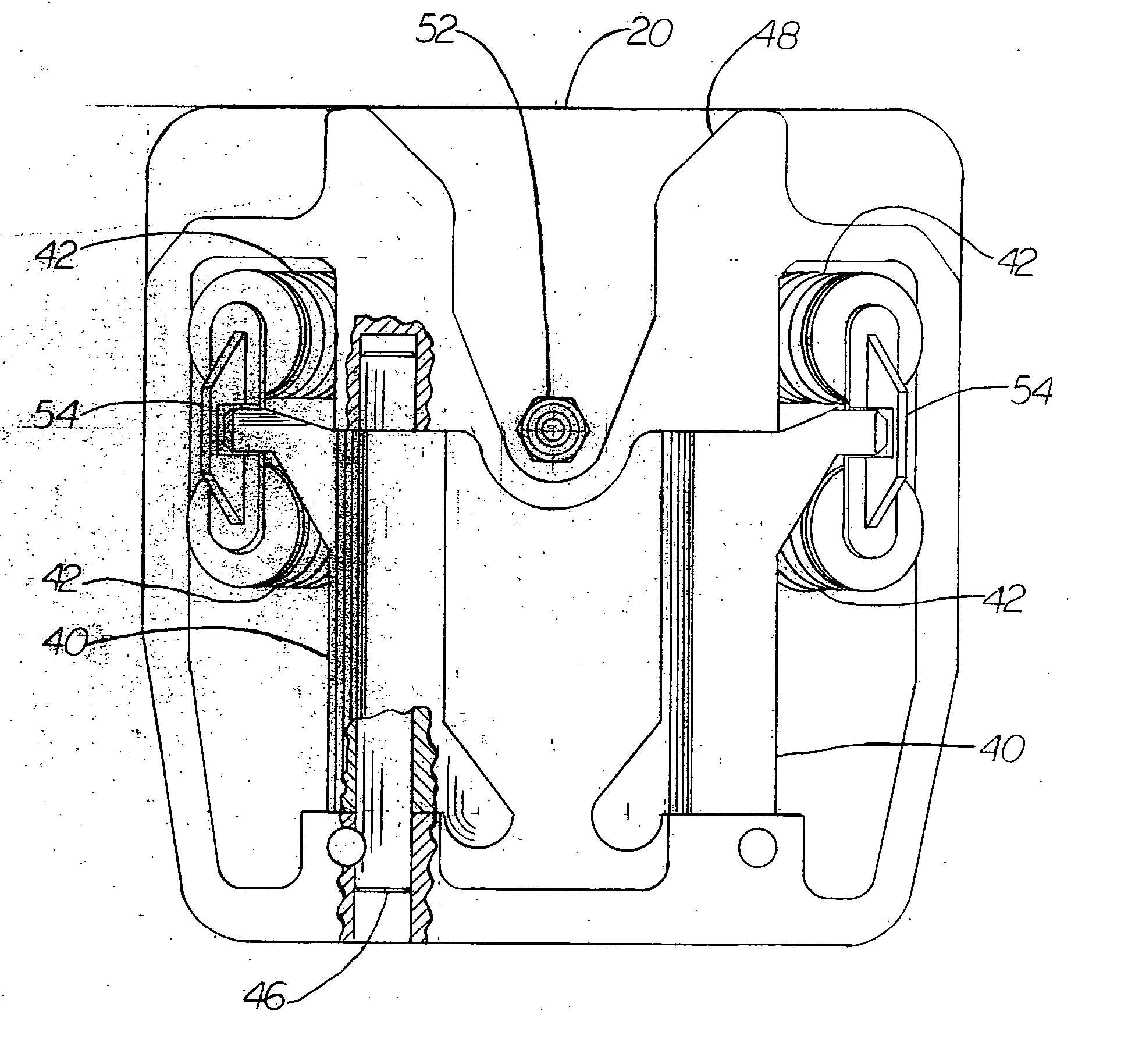

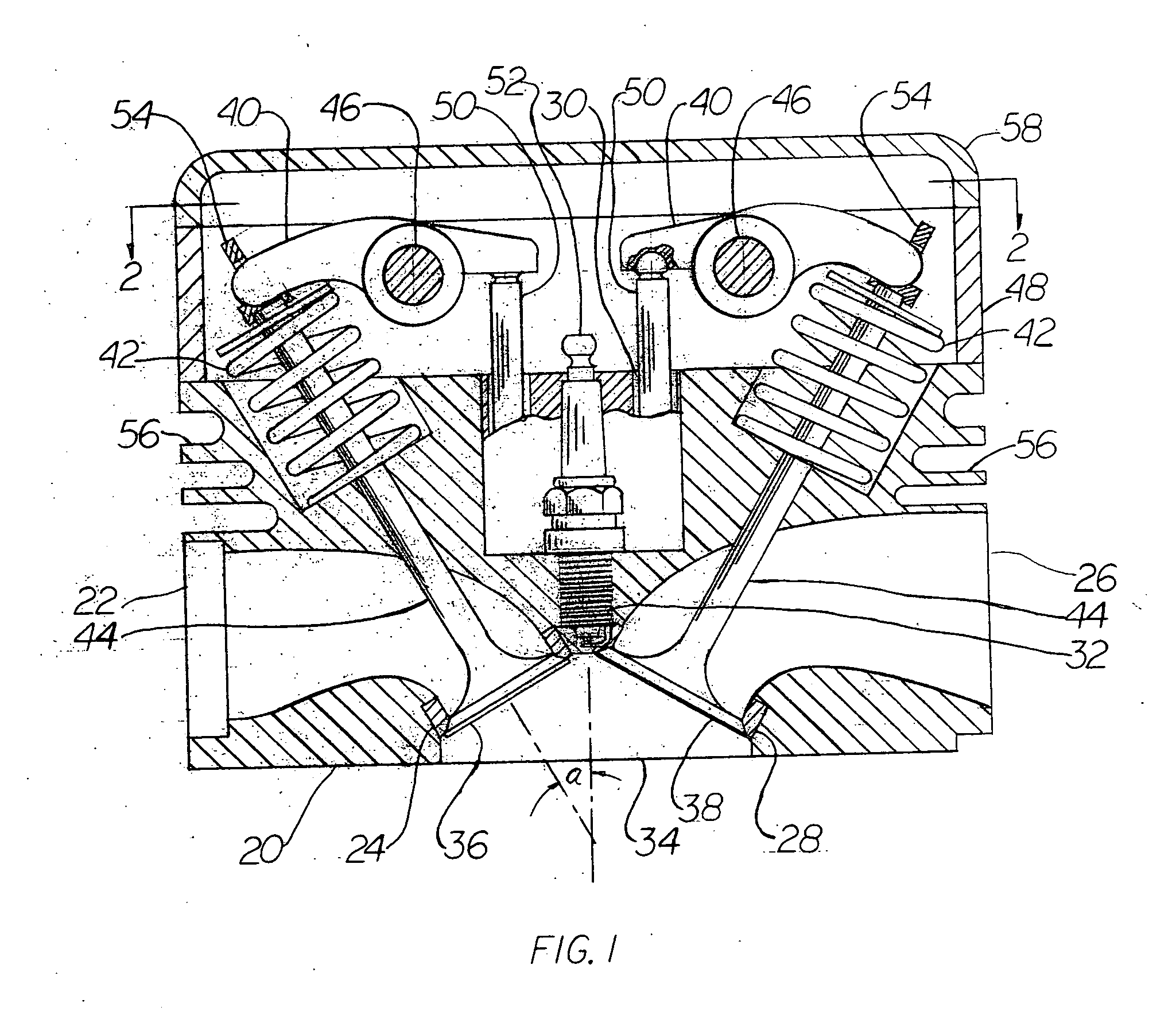

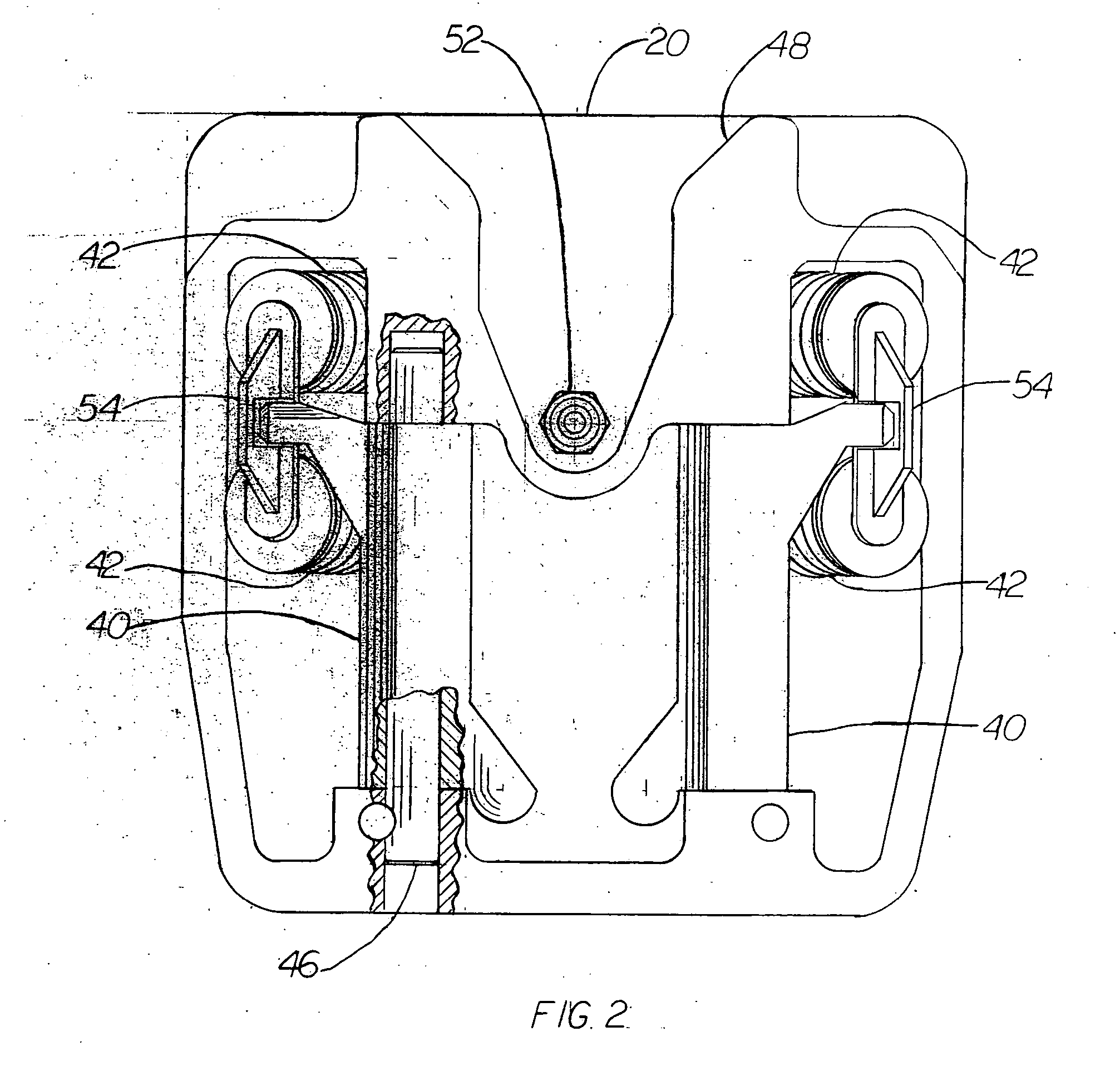

[0020] The best mode for carrying out the invention is presented in terms of a preferred embodiment and is illustrated in FIGS. 1 thru 3. The invention is limited is limited to a head assembly 20 for a gasoline engine having an internal cam shaft and plush rod system, specifically the Harley Davidson engine and copies thereof. The head 20 has a pair of exhaust valve ports 22 with seats 24 and a pair of intake valve ports 26 also with seats 28. The seats are alternatively formed with bushings, as depicted in FIG. 1.

[0021] The head 20 further contains a plurality of push rod passages 30 in linear alignment with the hydraulic valve lifters (not shown) one passage 30 for each pair of valves. Further, a threaded hole 32 for the spark plug is centrally located between the valves in the general area the ports 22 and 26 with the hole 32 recessed and the area thereunder forming a combustion chamber 34.

[0022] A pair of exhaust valves 36 are transversely parallel but are disposed at 25 to 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com