Water-absorbent adhesive compositions and associated methods of manufacture and use

a technology of adhesive compositions and water absorption, applied in the field of adhesive compositions, can solve the problems of affecting the application of compositions, affecting the adhesion performance of adhesives, and affecting the application effect of compositions,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Preparation and Properties of Adhesive Compositions Based on the Ladder-Like Interpolymer Complexes

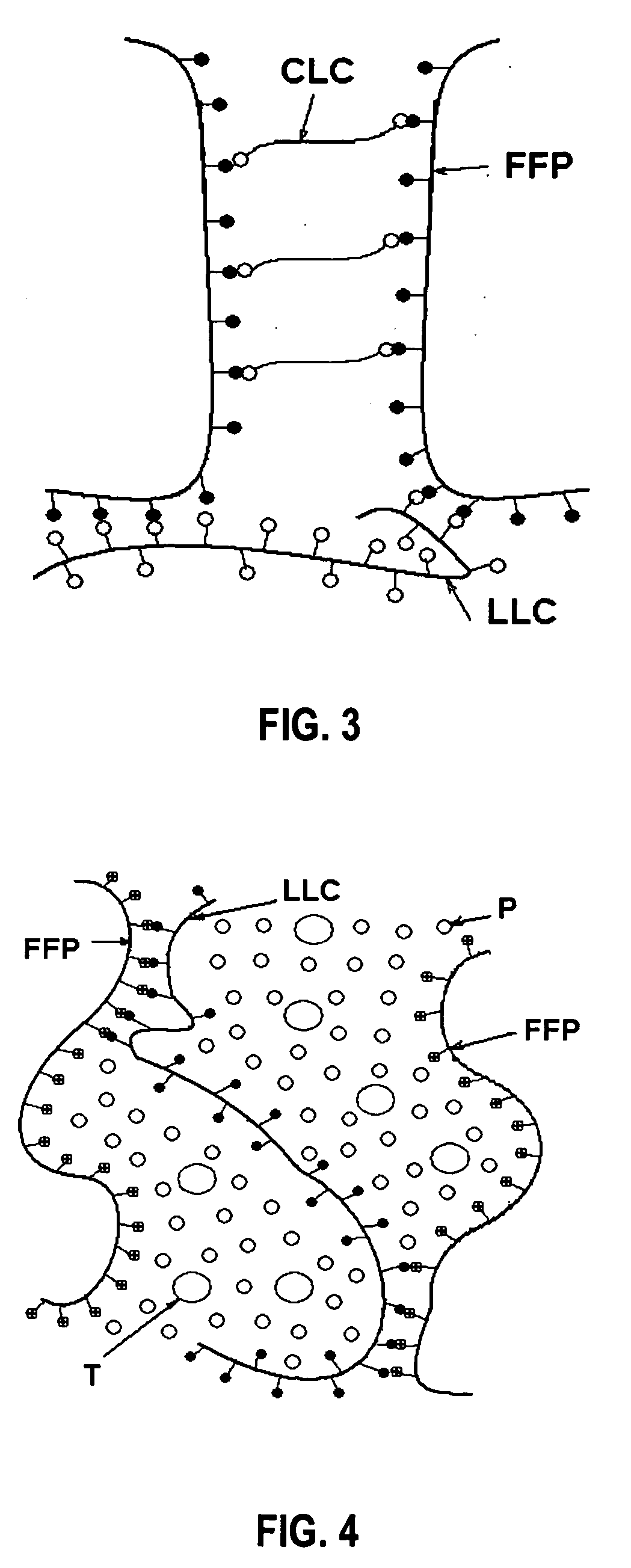

[0165] In the present example, Eudragit E-100 is used as the film-forming polymer, which is a copolymer of 2-dimethylaminoethyl methacrylate (DMAEMA), butyl methacrylate, and methyl methacrylate (2:1:1). The monomer units of DMAEMA are capable of forming electrostatic bonds with carboxyl groups in the ladder-like crosslinker, Eudragit L 100-55 and Eudragit S-100 (copolymer of methacrylic acid with methyl methacrylate (1:2). In this way, these blends represent triple blends of two Eudragit grade polymers (E-100 and L 100-55, or S-100) with appropriate plasticizers of hydrophobic units in Eudragit, such as tributyl citrate (TBC), triethyl citrate (TEC), acetyltributyl citrate (ATBC) and acetyltriethyl citrate (ATEC) (see Scheme in FIG. 4).

Blend composition, wt. %Ladder-likeFilm-formingcrosslinker:Carcass-SolSam-polymer:Eudragit LlikeFraction,SwellpleEudragit E-100100-55 or S-100crossl...

example 2

Improvement of Adhesion of the Ladder-Like Plasticized Interpolymer Complex by Incorporation of Tackifiers

[0172] U.S. Pat. No. 6,063,399 by Assmus et al. does not describe all the tools necessary to enhance the adhesion of triple Eudragit E-100—Eudragit L-100-55—TEC blends. One of such tools is mixing the Eudragit E-100—Eudragit L-100-55—TEC blends with tackifiers. Owing to optimum hydrophilic-hydrophobic balance, the amphiphilic adhesives based on Eudragit E-100—Eudragit L-100-55 complexes turned out to be miscible with tackifiers, which are extensively used in adhesive technology to improve tack. As follows from the data shown in Table and FIG. 8, adding the tackifier Sylvagum RE 85K (glycerol ester of tall oil rosin) improves essentially the adhesive performance of blended adhesive. While plasticizers contribute mainly to the increase of material capability to develop large deformations under detaching stress, the tackifier enhances appreciably its cohesive strength by the incre...

example 3

Adhesive Compositions Based on the Carcass-Like Complex of Eudragit E-100 Polybase and its Combination with the Ladder-Like Electrostatic Crosslinking

[0177] The film forming polymer, exemplified in this description with Eudragit E-100 polybase, may be converted into the form of pressure sensitive adhesive not only by plasticizing with TEC, but and by adding into this blend higher carboxylic acids having 8 to 20 carbon atoms and dicarboxylic acids having 2 to 8 carbon atoms (U.S. Pat. No. 5,113,970 to Petereit and Roth). As follows from the data presented in Table Ex.3 (see examples 3a and 3b), the blends of Eudragit E-100 with TEC and adipic acid (AA, dicarboxylic acid having 6 carbon atoms) are good skin contact adhesives. Forming two electrostatic bonds through both terminal carboxyl groups at AA short chain, the AA acts as the carcass-like crosslinker of trialkylamino groups in Eudragit E-100 polybase. Additional incorporation of AA into the plasticized ladder-like Eudragit E-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com