Ceramic article and method of manufacture therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Several prior art casting and rapid prototyping processes have been described hereinabove. Understanding these examples of prior art is deemed useful in understanding the present invention. Note that the prior art casting processes described hereinabove include drying operations, where water contained in ceramic molds made by wet ceramic processes is removed. Such drying operations are very time-consuming, typically requiring several days. The processes of the present invention eliminate or significantly reduce the drying time associated with these prior-art casting processes.

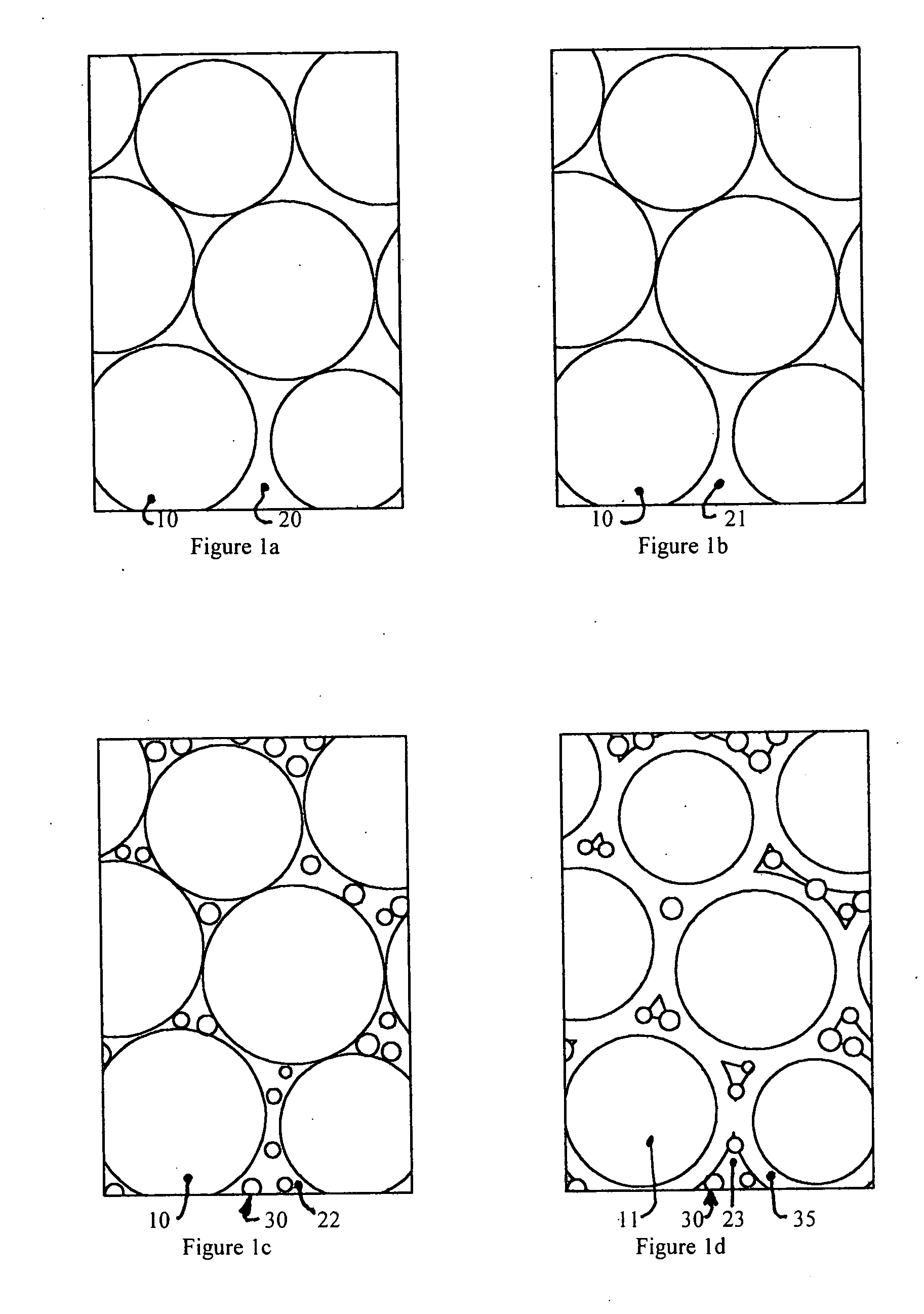

[0026] The ceramic article of the present invention is advantageously described with reference to the Figure described hereinabove. The manufacturing process for that ceramic article is likewise advantageously described with reference to the Figure.

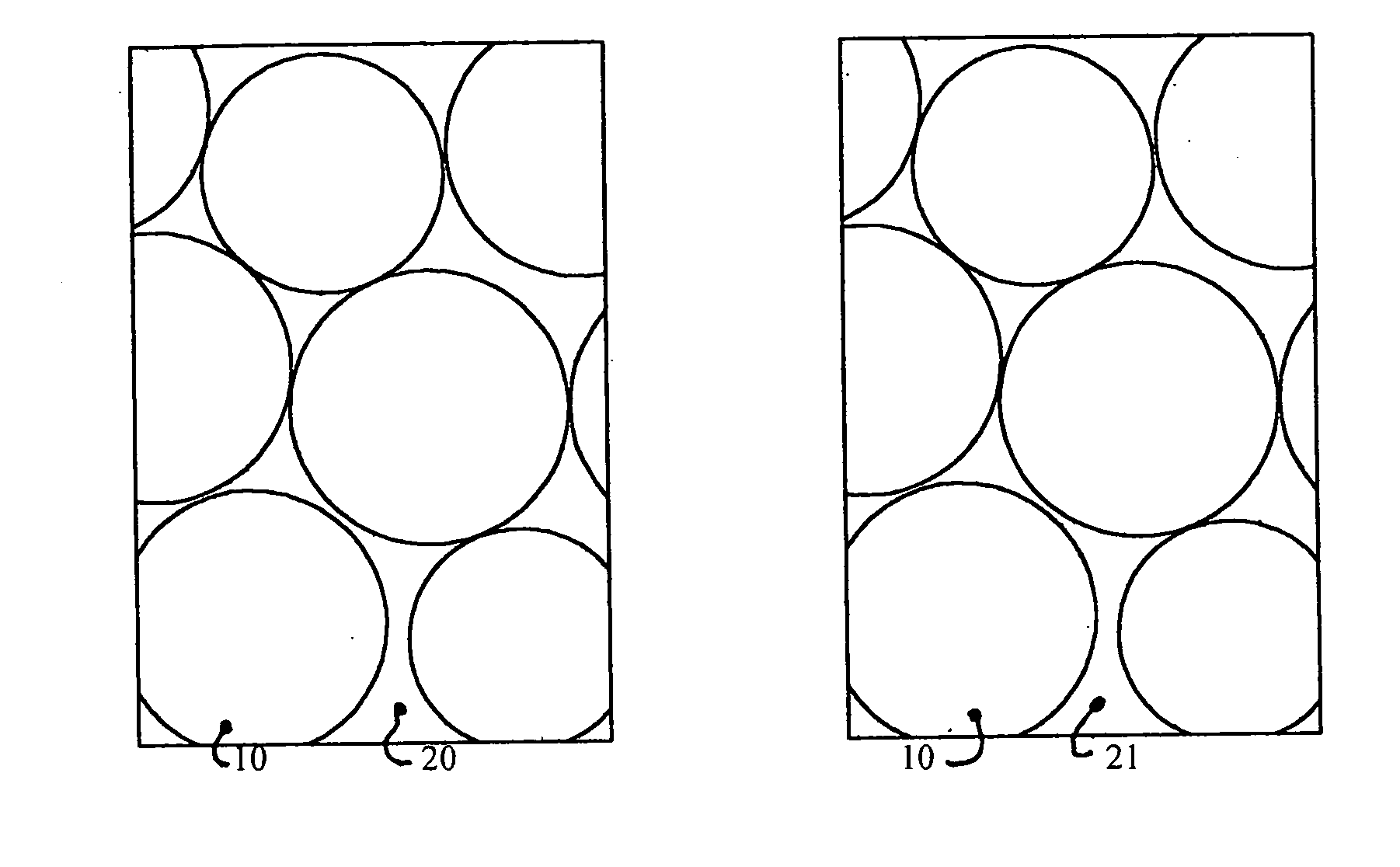

[0027] The chemical transformations that typically occur during practice of the present invention are illustrated in FIG. 1, which comprises four schematic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Composition | aaaaa | aaaaa |

| Interaction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com