Electrode structure of organic electroluminescent display panel and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

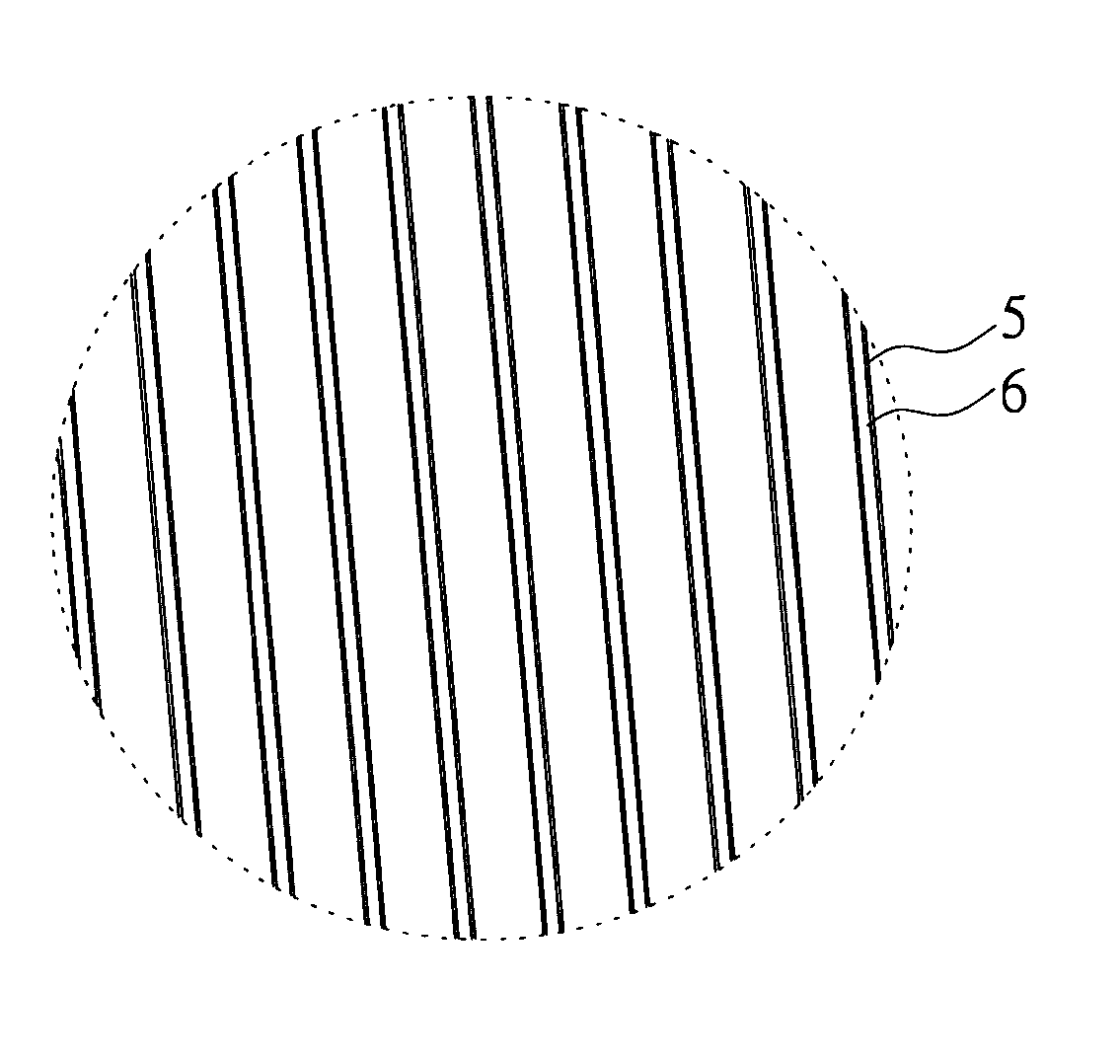

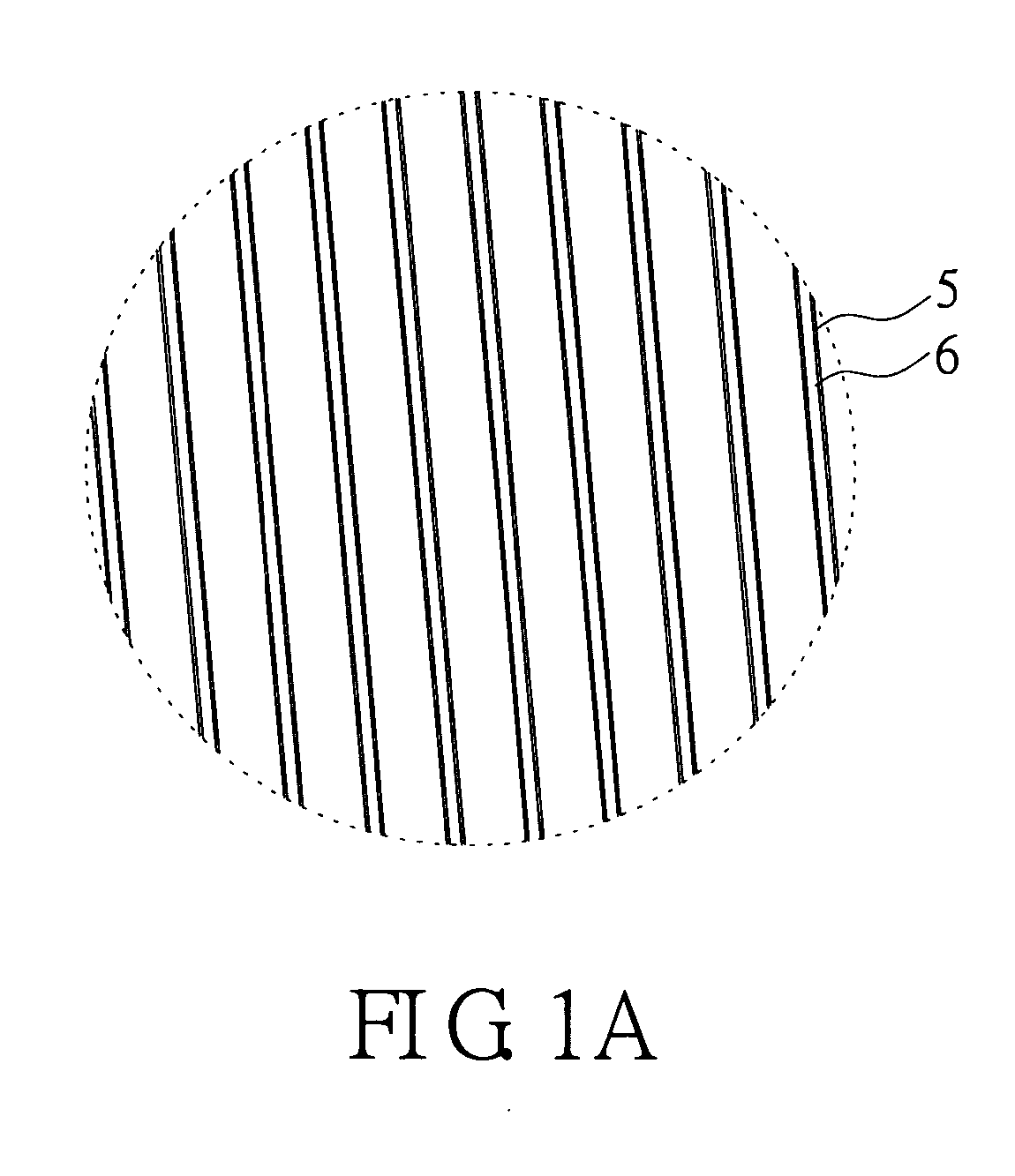

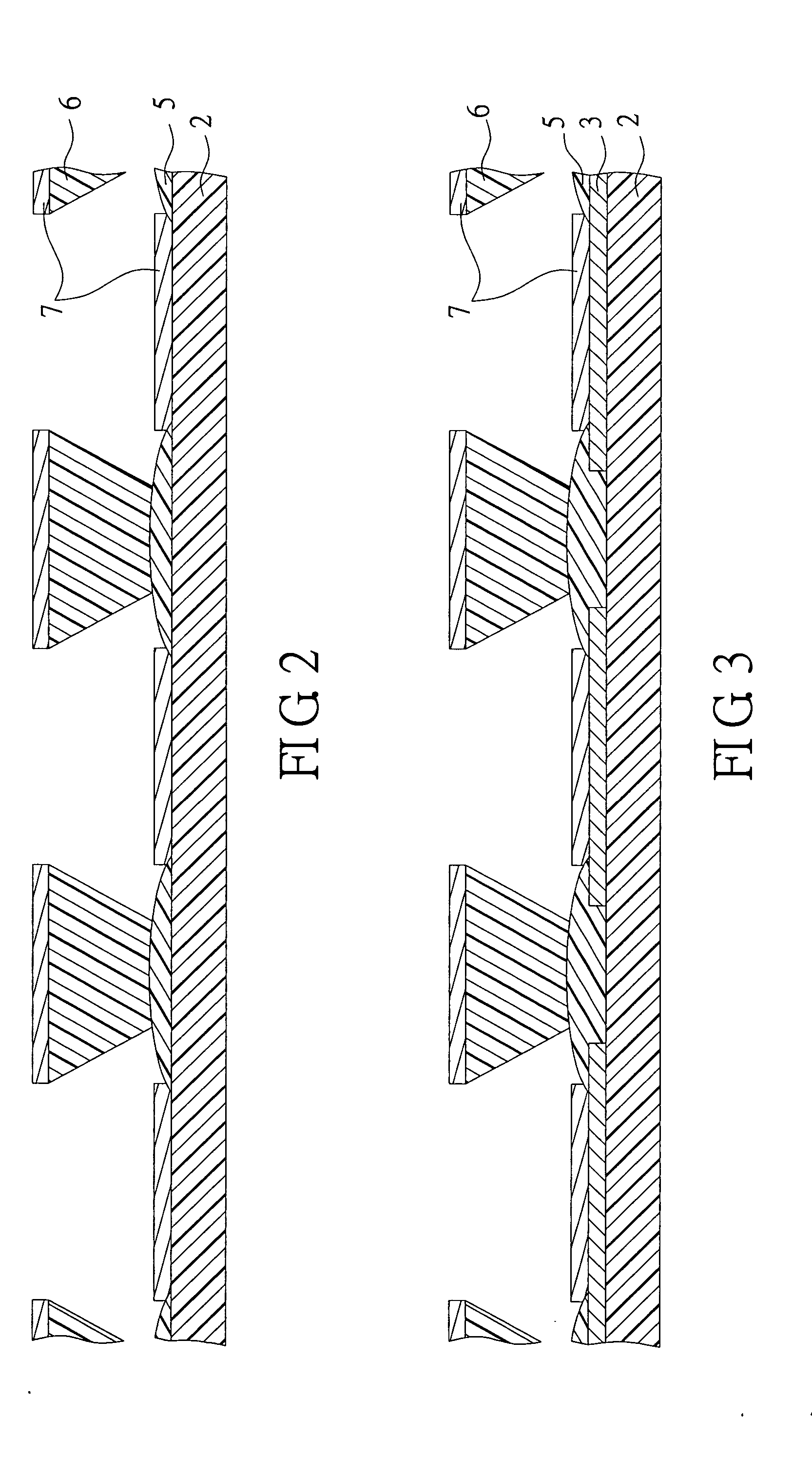

[0021] the electrode structure of the organic electroluminescent display panel 10 of the present invention as shown in FIG. 2 comprises a transparency substrate 2, an isolation area 5 provided on the transparency substrate 2 as isolation, a separation area 6 provided on the isolation area 5 with a raised predetermined height to separate electrical interference, and at least one metallic conductive layer 7 provided on the transparency substrate 2 and the separation area 6. The isolation area 5 isolates the electrical connection of adjacent leading wires. The separation area 6 with the predetermined height separates from and electrically isolates the metallic conductive layers 7 respectively provided on the separation area 6 and the transparency substrate 2 and further avoids from electrical interference of adjacent leading wires. Besides, the at least one metallic conductive layer 7 on the separation area 6 and the at least one metallic conductive layer 7 on the transparency substrat...

second embodiment

[0022] the electrode structure of the organic electroluminescent display panel 10 of the present invention as shown in FIG. 3 comprises a transparency substrate 2, a leading wire pattern layer 3 provided on the transparency substrate 2, an isolation area 5 provided on the leading wire pattern layer 3 as isolation, a separation area 6 provided on the isolation area 5 with a raised predetermined height to separate electrical interference, and at least one metallic conductive layer 7 provided on the leading wire pattern layer 3 and the separation area 6. The isolation area 5 isolates the electrical connection of adjacent leading wires. The separation area 6 with the predetermined height separates from and electrically isolates the metallic conductive layers 7 respectively provided on the separation area 6 and the leading wire pattern layer 3 and further avoids from electrical interference of adjacent leading wires. Besides, the at least one metallic conductive layer 7 on the separation...

third embodiment

[0023] the electrode structure of the organic electroluminescent display panel 10 of the present invention as shown in FIG. 4 comprises a transparency substrate 2, a leading wire pattern layer 3 provided on the transparency substrate 2, at least one auxiliary metallic conductive layer 4 provided on the leading wire pattern layer 3, an isolation area 5 provided on the leading wire pattern layer 3 as isolation, a separation area 6 provided on the isolation area 5 with a raised predetermined height to separate electrical interference, and at least one metallic conductive layer 7 provided on the auxiliary metallic conductive layer 4 and the separation area 6. The isolation area 5 isolates the electrical connection of adjacent leading wires. The separation area 6 with the predetermined height separates from and electrically isolates the at least one metallic conductive layer 7 provided on the separation area 6 and the at least one metallic conductive layer 7 provided on the auxiliary met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com