Catheter having a funnel-shaped occlusion balloon of uniform thickness and methods of manufacture

a technology of occlusion balloon and funnel-shaped catheter, which is applied in the field of catheters having occlusion balloons of uniform thickness, can solve the problems of high chance of embolic material release, ischemia may pose a serious threat to the health or life of patients, and variability in deployment, so as to improve the manufacture of occlusion balloons. the effect of improving the manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

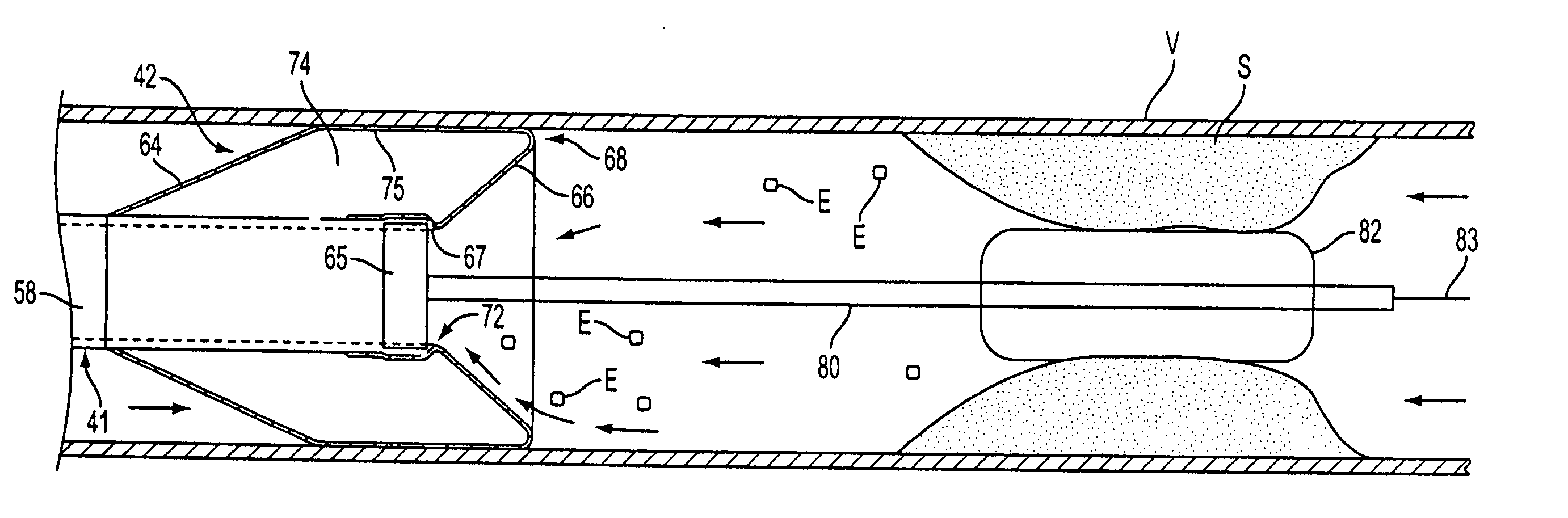

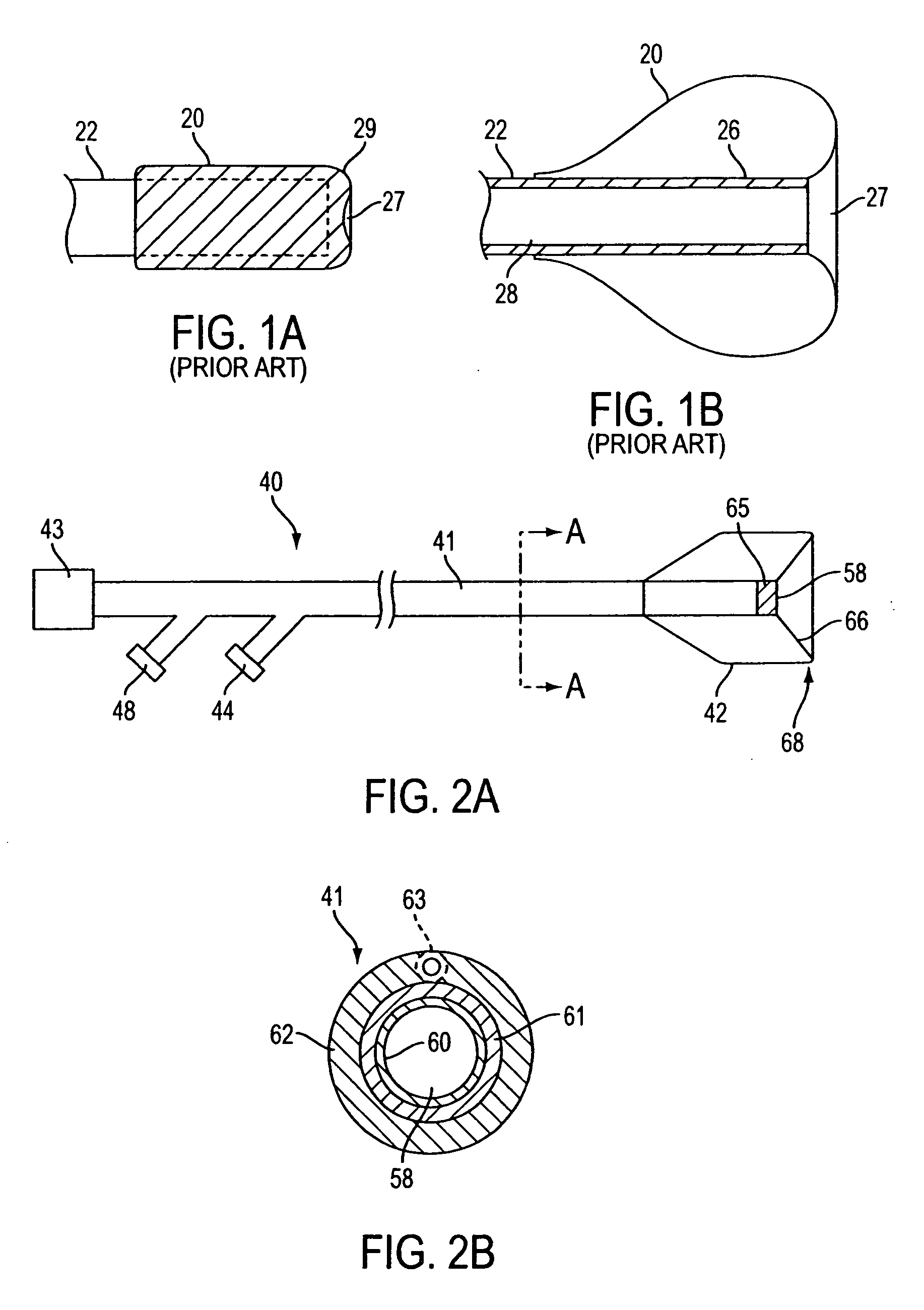

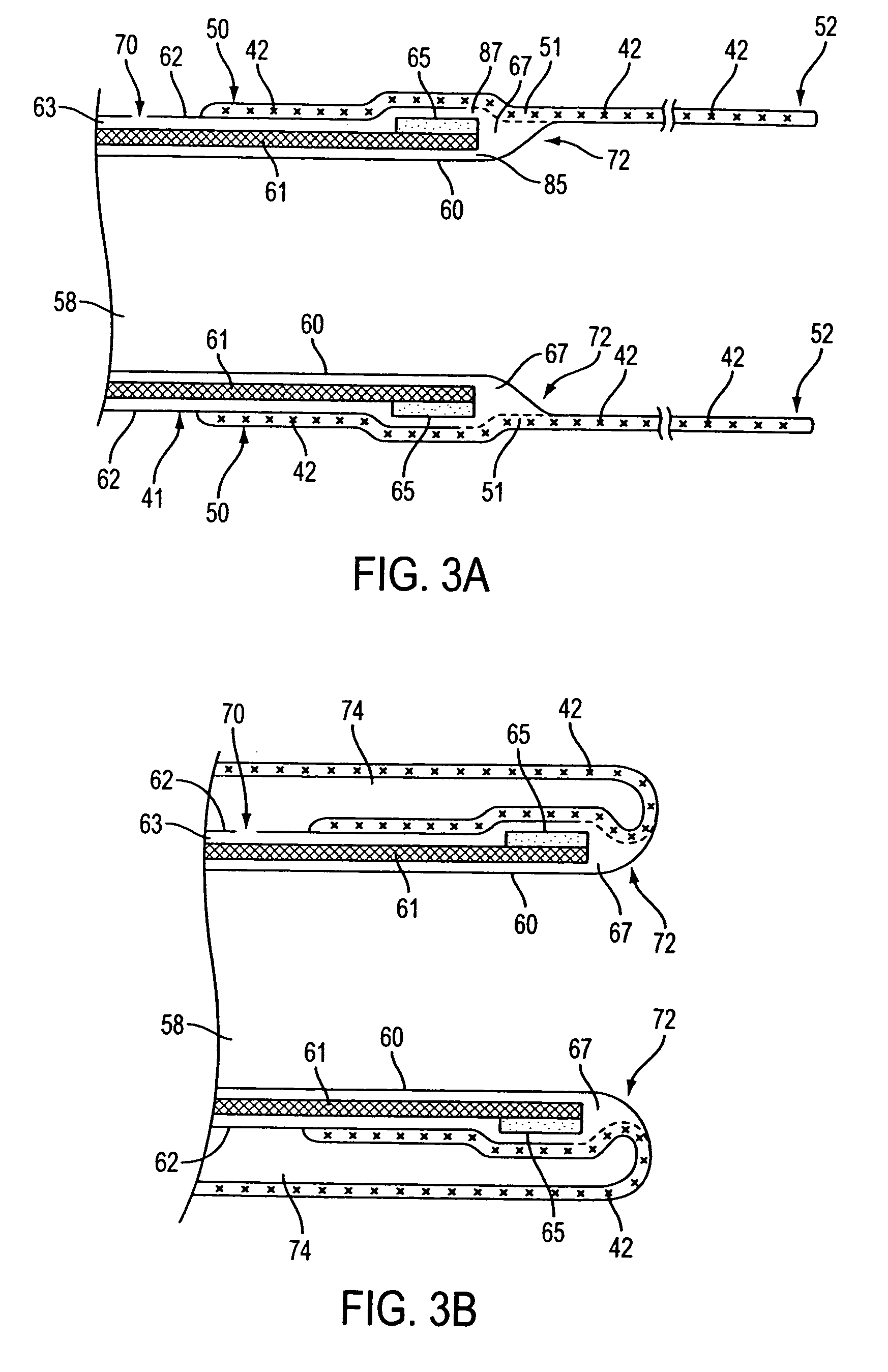

[0023] Referring to FIGS. 1A-1B, a bell-shaped occlusion balloon, as described in applicant's commonly assigned allowed U.S. patent application Ser. No. 09 / 418,727, filed May 8, 2001, which is incorporated herein by reference, is described. Occlusion balloon 20 is shown in contracted and deployed states in FIGS. 1A and 1B, respectively. Balloon 20 is affixed to distal end 26 of catheter 22, for example, by gluing or a melt-bond, so that opening 27 in balloon 20 leads into lumen 28 of catheter 22. Balloon 20 preferably is wrapped and heat treated during manufacture so that distal portion 29 of the balloon extends beyond the distal end of catheter 22 and provides an atraumatic tip or bumper for the catheter. In accordance with manufacturing techniques which are known in the art, occlusion balloon 20 comprises a compliant material, such as polyurethane, latex or polyisoprene which has variable thickness along its length to provide a bell-shape when inflated.

[0024] As described hereina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com