Wafer processing apparatus capable of controlling wafer temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

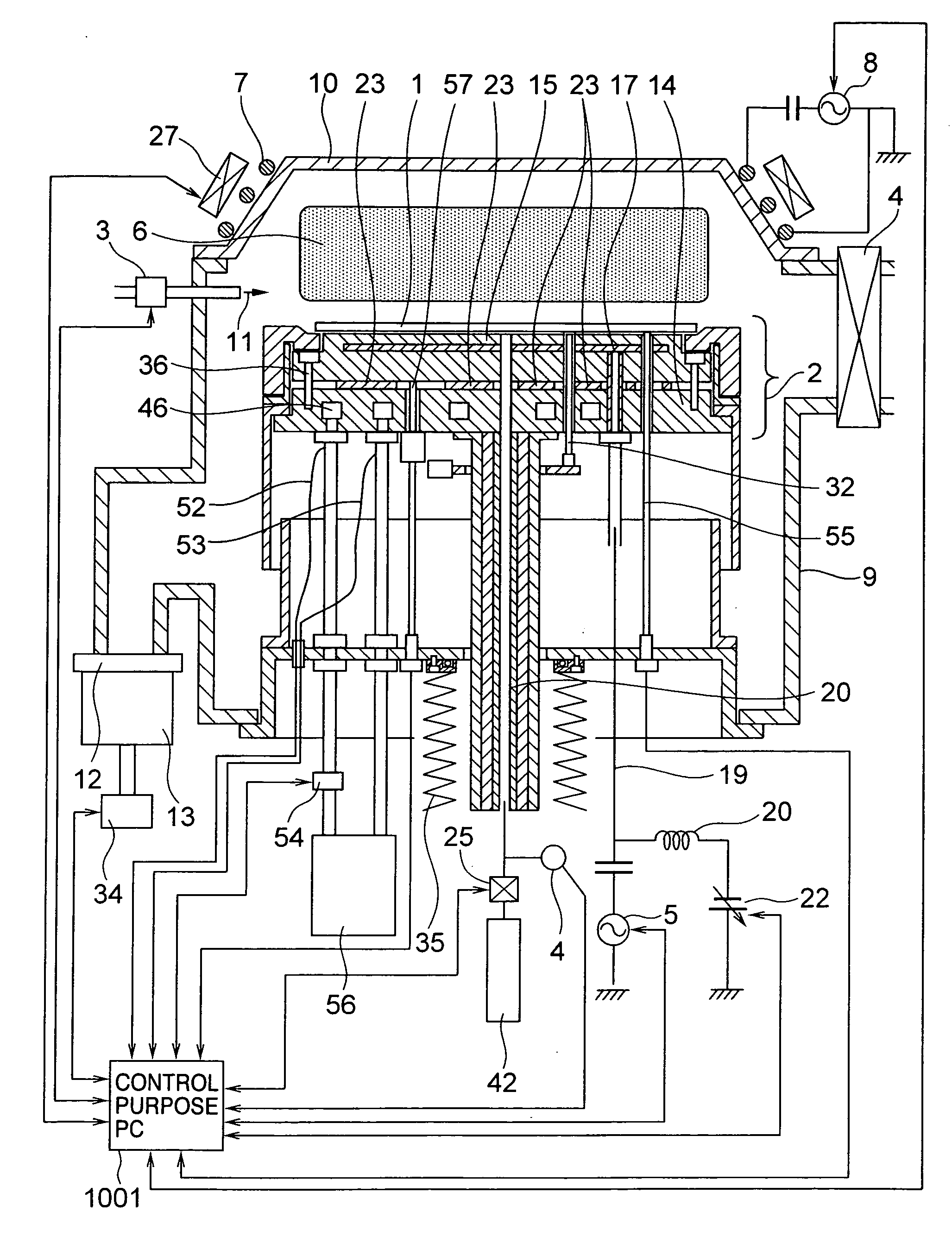

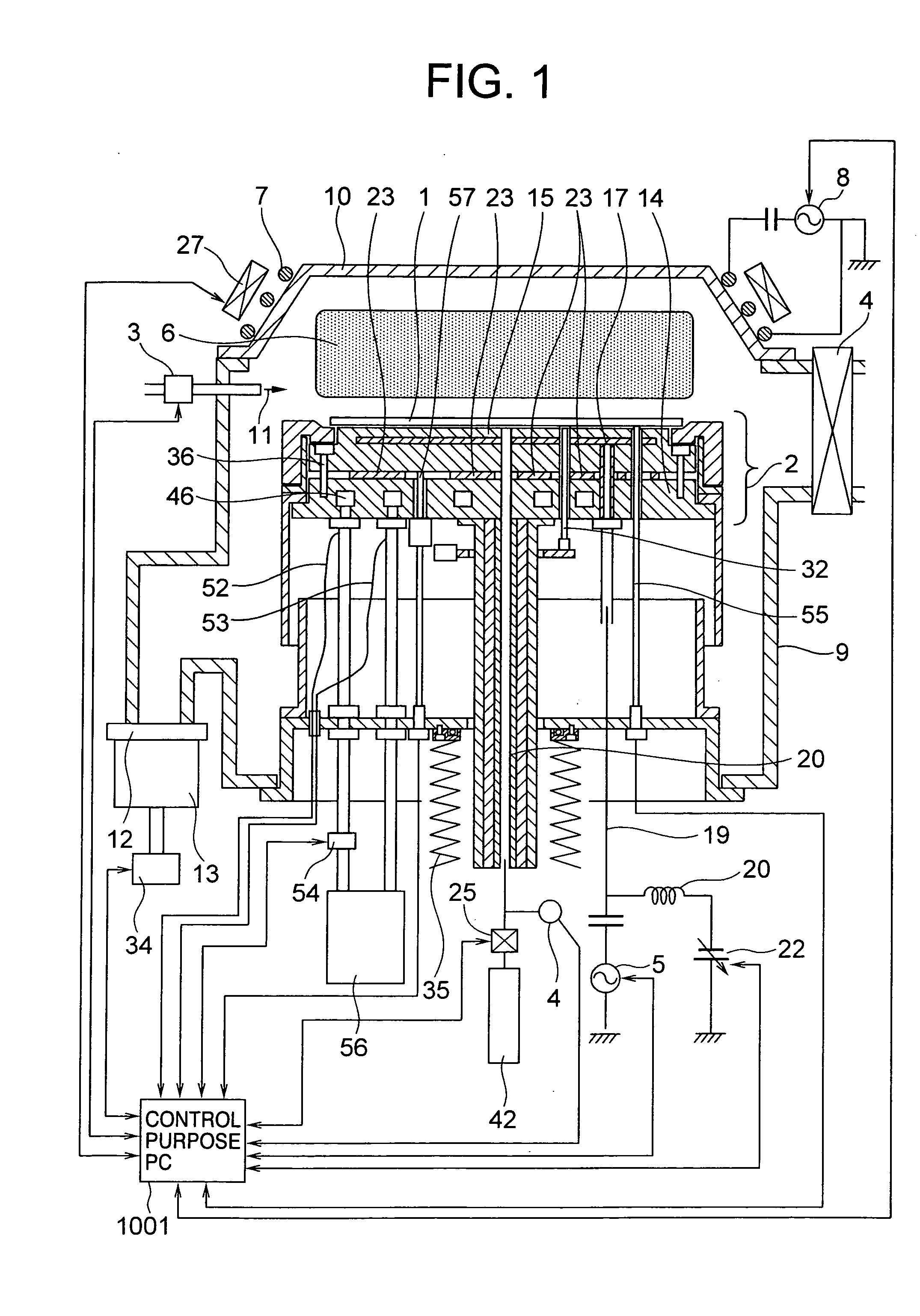

[0030] An embodiment of a wafer processing apparatus according to the invention will be described in detail with reference to the drawings. FIG. 1 shows one example of the etching apparatus to which this embodiment of the invention is applied.

[0031] Referring to FIG. 1, a wafer 1 is placed on a wafer stage 2 within a vacuum chamber 9. At this time, a bell jar 10 made of aluminum is secured to the top of the vacuum chamber 9 to keep the inside airtight.

[0032] The inside of the vacuum chamber 9 is evacuated by a turbo-molecular pump 13 and an oil-less pump 34, and then an etching gas 11 is introduced while it is being controlled in its flow rate by the flow controller 3. At this time, the inside of the vacuum chamber 9 is kept at a proper pressure by adjusting the opening valve travel of a valve 12 provided on the upstream of the turbo-molecular pump 13.

[0033] A coil 7 is provided to surround the bell jar 10, and a high-frequency voltage of, for example, 13.56 MHz is supplied to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com