Collimator fabrication

a technology of collimator and fabrication method, which is applied in the direction of instruments, nuclear engineering, and handling using diaphragms/collimeters, etc., can solve the problems of non-redundancy design arrays, and achieve the effect of low error tolerance, precise dimensions and low error toleran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

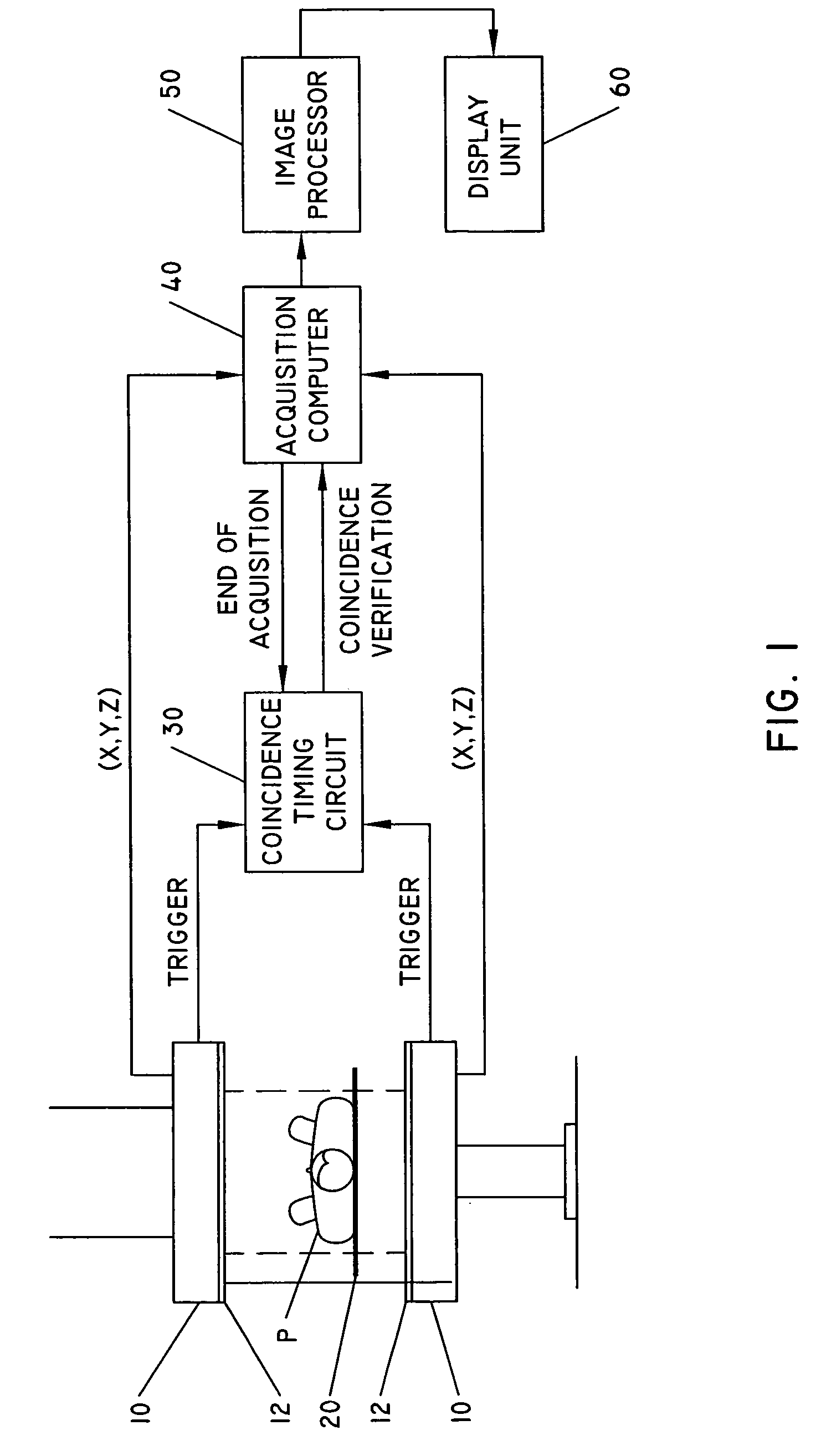

[0039] Referring now in greater detail to the drawings, wherein the showings are for the purpose of illustrating preferred embodiments of the invention only and not for the purpose of limiting the invention, FIG. 1 shows a block diagram of a prior art gamma ray detector system used for diagnostic purposes. A pair of gamma detectors 10, each optically coupled to a scintillation crystal 12, are disposed parallel to each other. Detector pair 10 is mounted on a gantry that can rotate about a patient P resting on a table 20. Additionally, either detector pair 10 or patient P can be transversely displaced in the direction perpendicular to the plane of the figure. This configuration allows for total body scanning and / or static imaging, both well-known techniques in NM coincidence measurements.

[0040] System hardware and software, schematically described in FIG. 1 by blocks 30, 40, 50 and 60, allows for coincidence measurements in accordance with technology well known in the art. Thus, no f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com