Compressor and hermetic housing with minimal housing ports

a compressor and hermetic housing technology, applied in the direction of machines/engines, positive displacement liquid engines, lighting and heating apparatus, etc., can solve the problems of increasing the cost of the compressor and the number of locations on the compressor housing at which fluid leakage could potentially occur, so as to reduce the cost of the compressor and simplify the manufacture of the compressor assembly. , the effect of reducing the initial cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

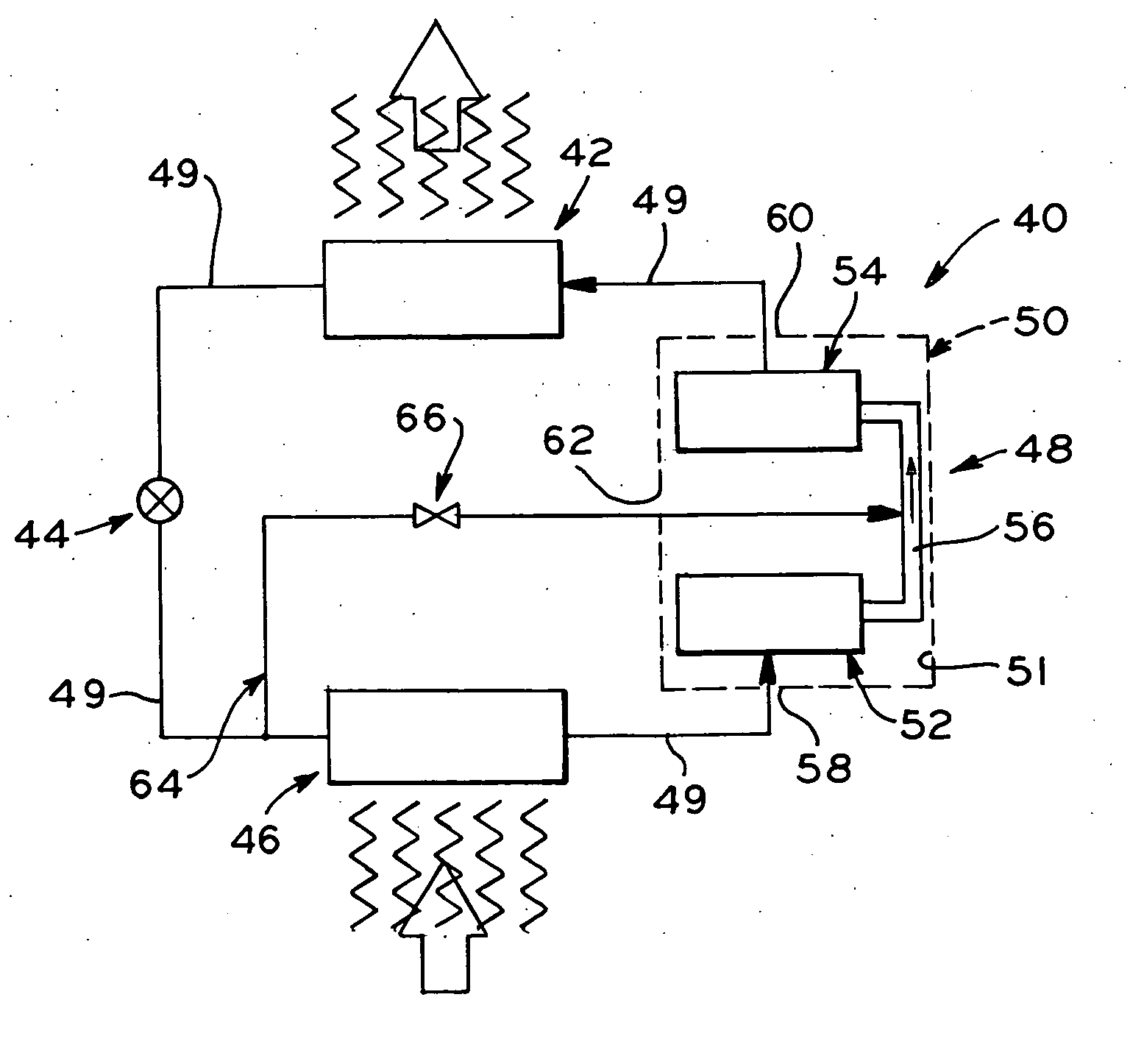

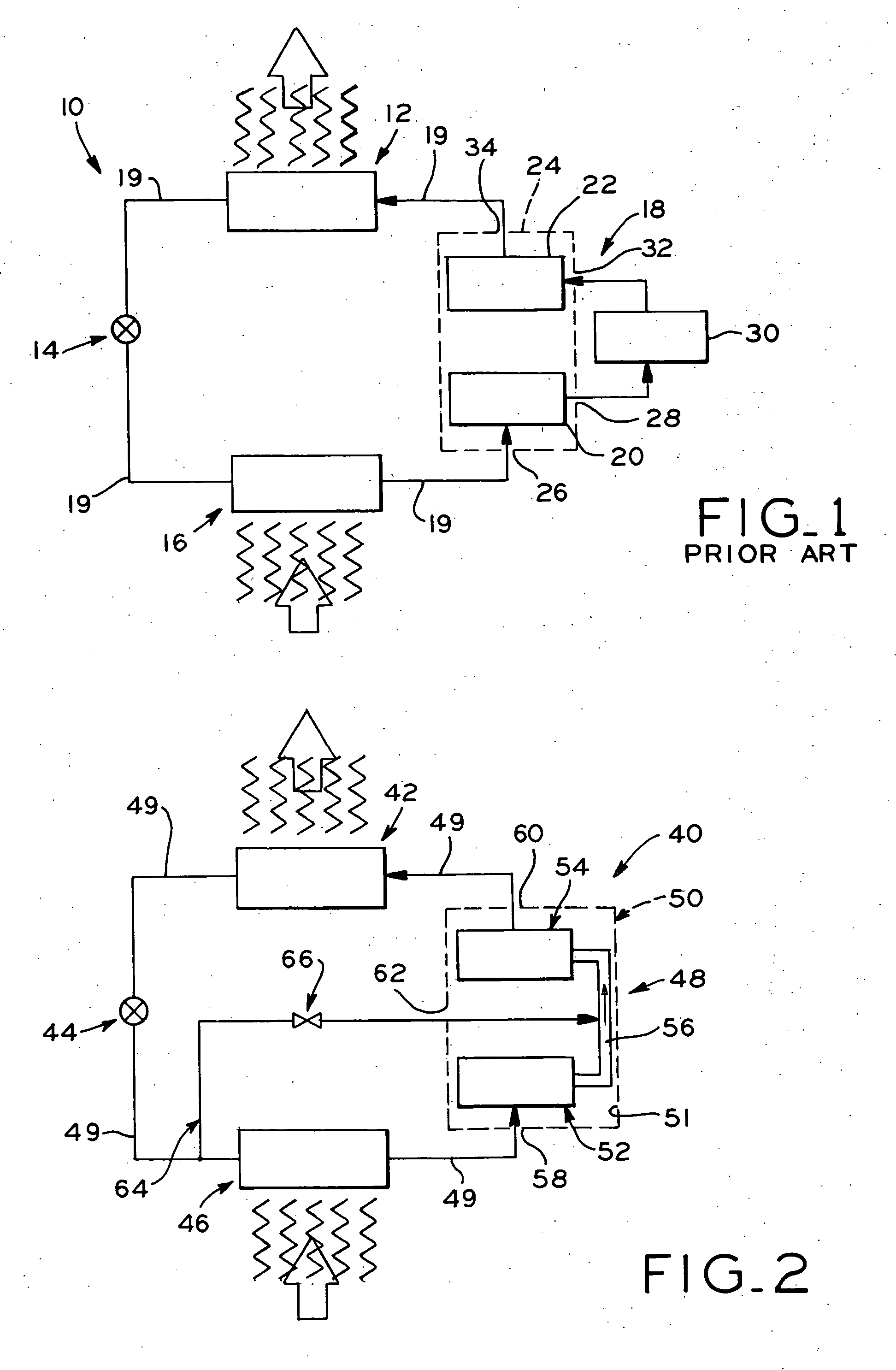

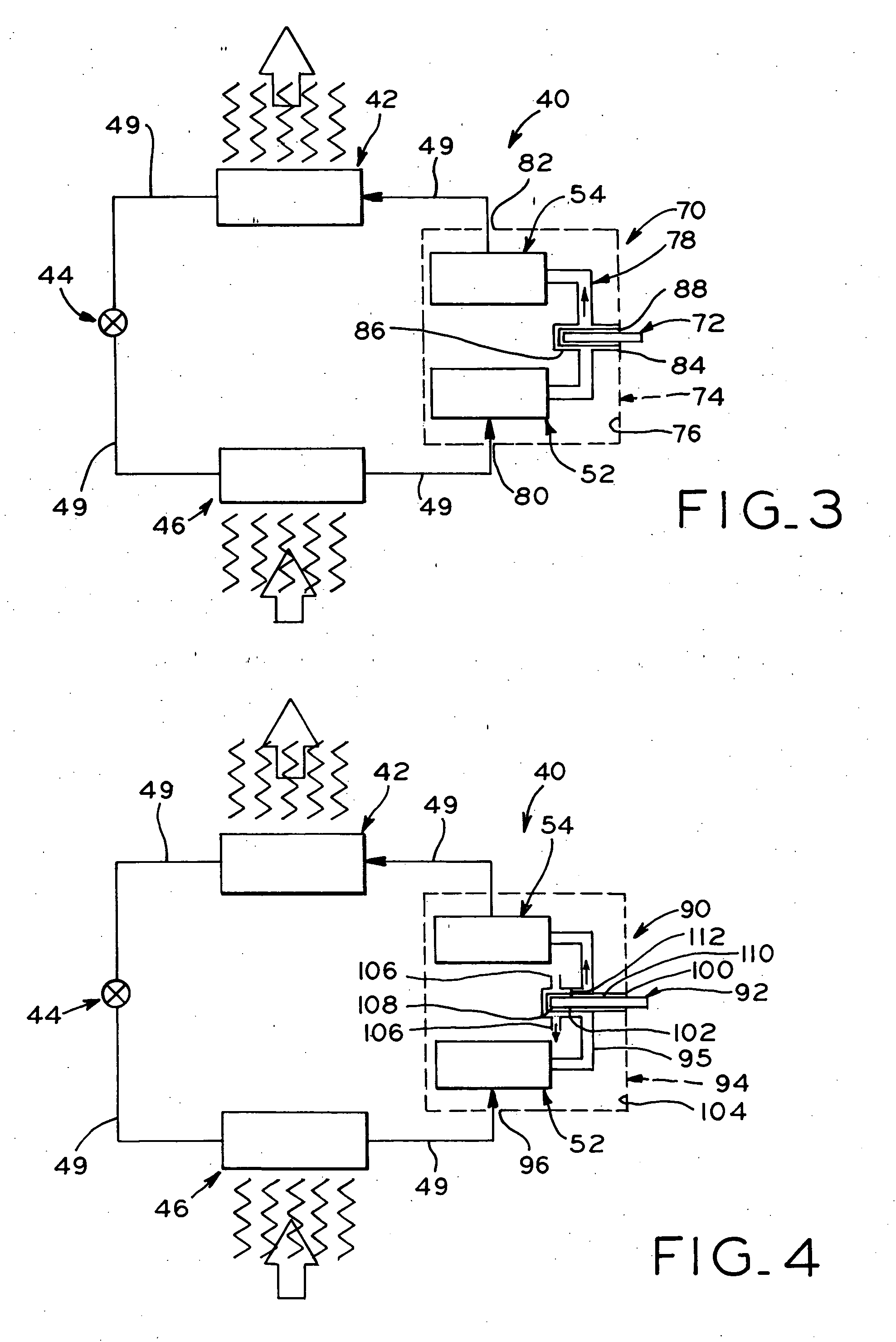

[0023] Referring to FIG. 2, vapor compression system 40 is a closed loop fluid circuit through which a working fluid is circulated. Vapor compression system 40 has operably disposed therein, in serial order, first heat exchanger 42, expansion device 44, second heat exchanger 46, and compressor assembly 48. In the illustrated vapor compression system 40, the working fluid is carbon dioxide and vapor compression system 40 is a transcritical system. Consequently, first heat exchanger 42 is a gas cooler wherein the carbon dioxide within gas cooler 42 is at a supercritical pressure while the carbon dioxide within second heat exchanger or evaporator 46 is at a subcritical pressure. The components of vapor compression system 40 are fluidly connected by a plurality of conduits 49. Although a charge of carbon dioxide flows through the fluid circuit in the illustrated embodiments, other refrigerants may alternatively be employed with the present invention.

[0024] The use of carbon dioxide as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com