Method and system for controlling a machine tool with direct transfer of machining data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

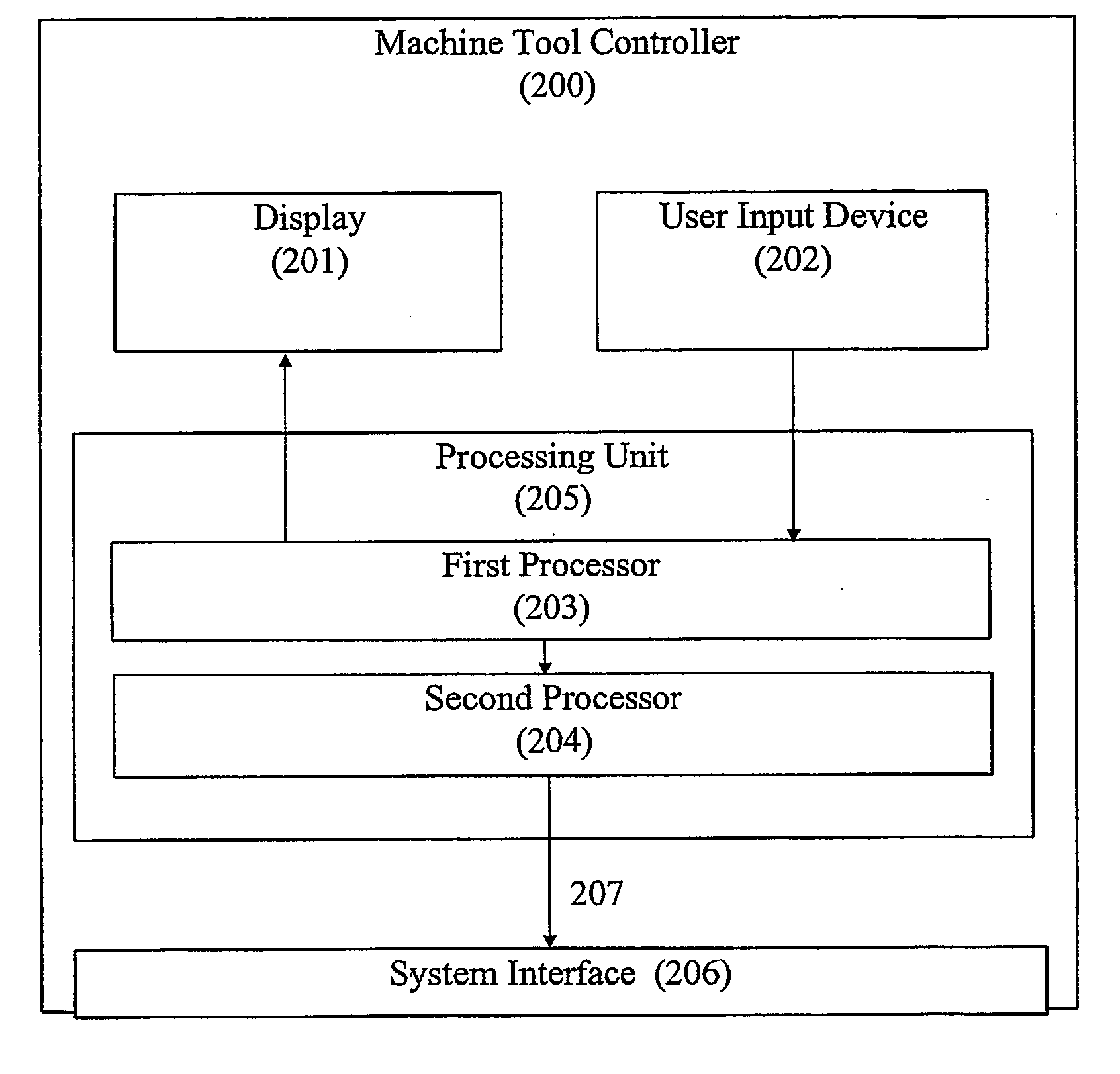

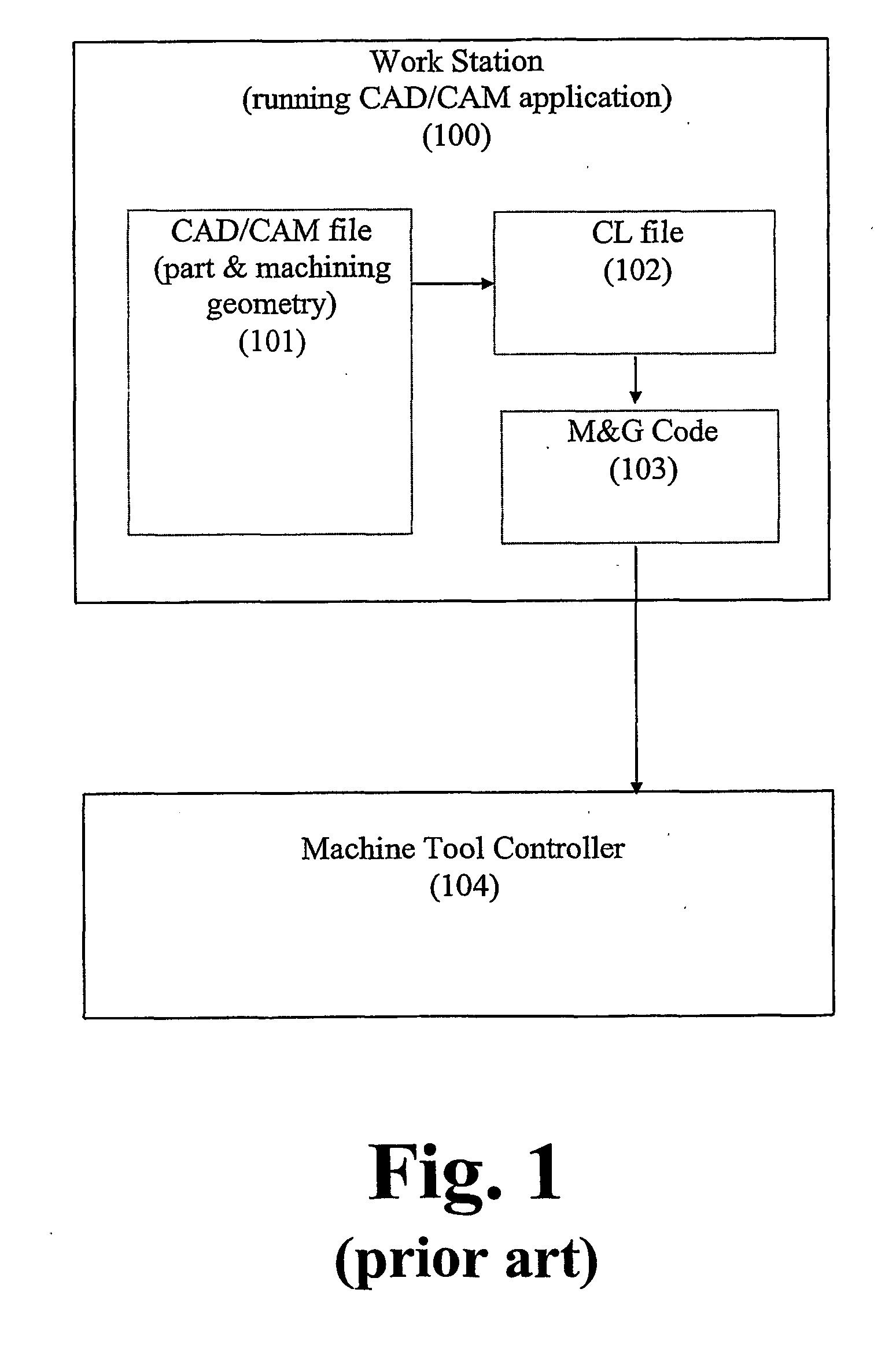

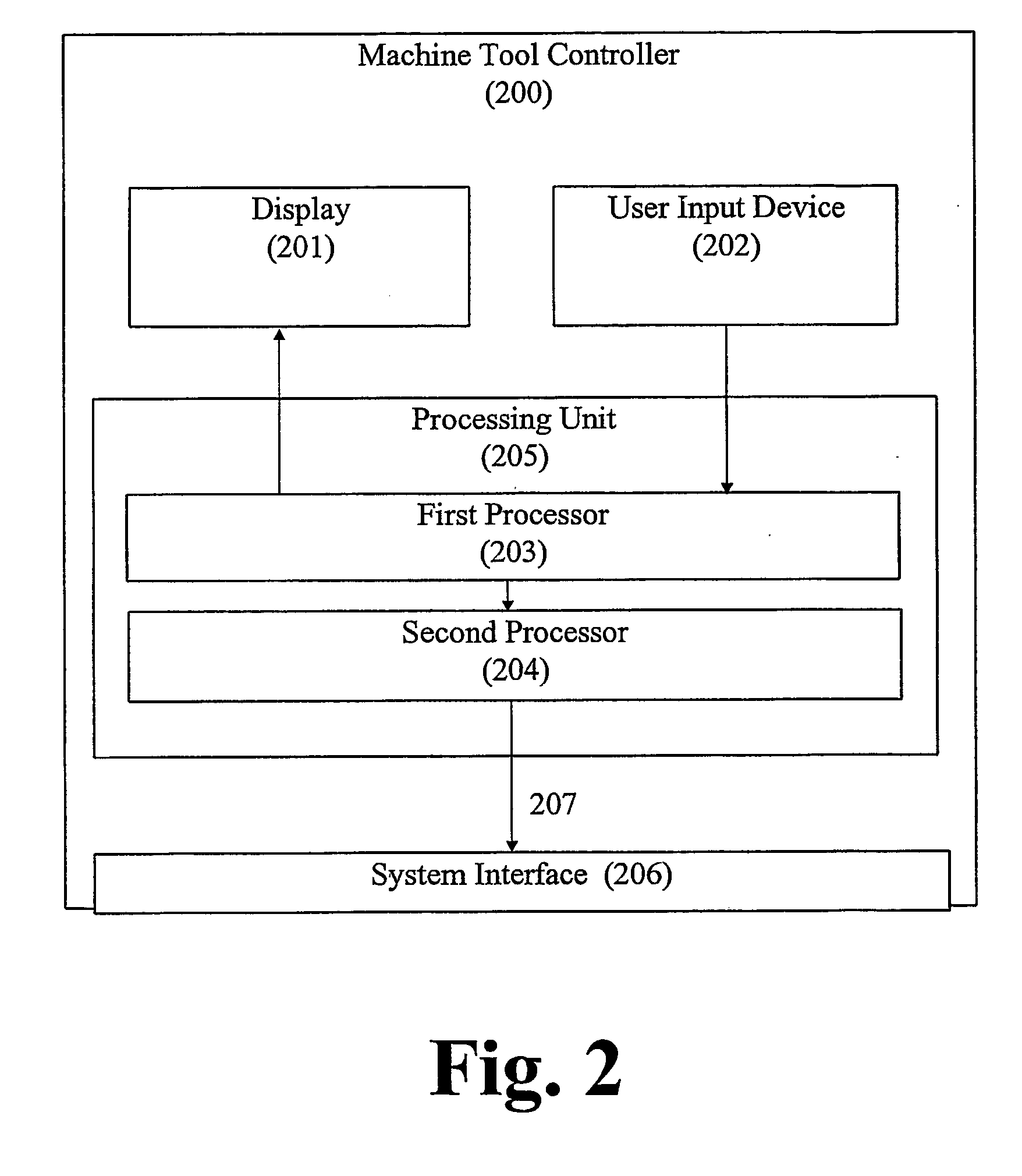

[0038] The present invention provides a new, open, software architecture for digital control interfaces. As will be recognized by those of skill in the art, this new interface architecture can be utilized in any system in which control data is sent to a servo-controlled machine that is interfaced with a control system.

[0039] A preferred application of the digital control interface and accompanying principles of the present invention is to the machine tool controller of a machine tool for making machine parts according to predetermined specifications. For example, the present invention provides a new paradigm in which it is possible to utilize the abilities of existing design applications, such as CAD / CAM packages, and machine tool controllers to more directly and efficiently transfer a CAD-generated design of a part into the instructions necessary to appropriately control the machine tool. The process of the present invention will be referred to as “Direct Machining.”

[0040] Direct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com