Exposure apparatus, exposure method, and method for producing device

a technology of exposure apparatus and exposure method, which is applied in the direction of photomechanical apparatus, printing, instruments, etc., can solve the problems of insufficient margin, inconvenience, and difficulty in matching the substrate surface with respect to the image plane of the projection optical system

- Summary

- Abstract

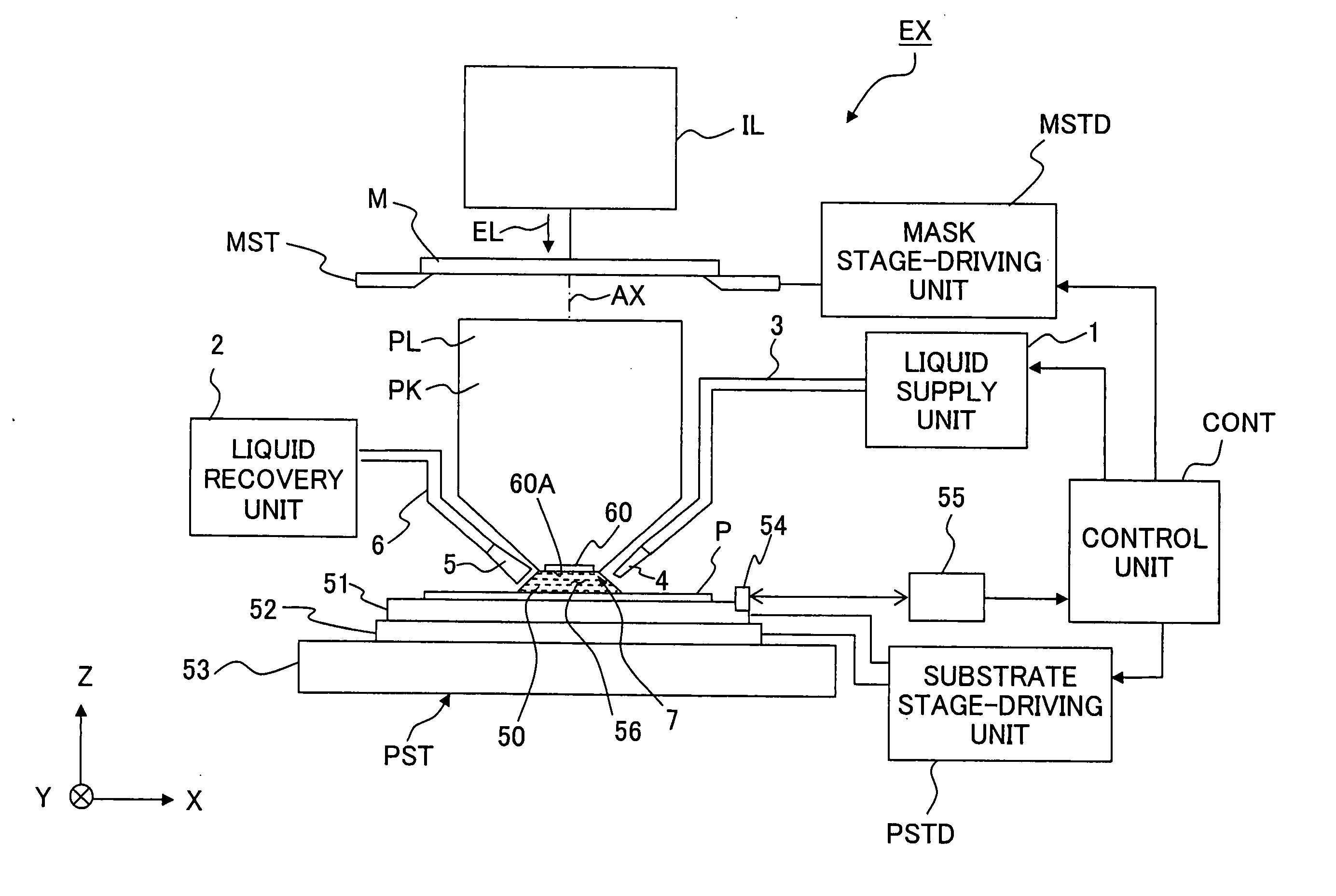

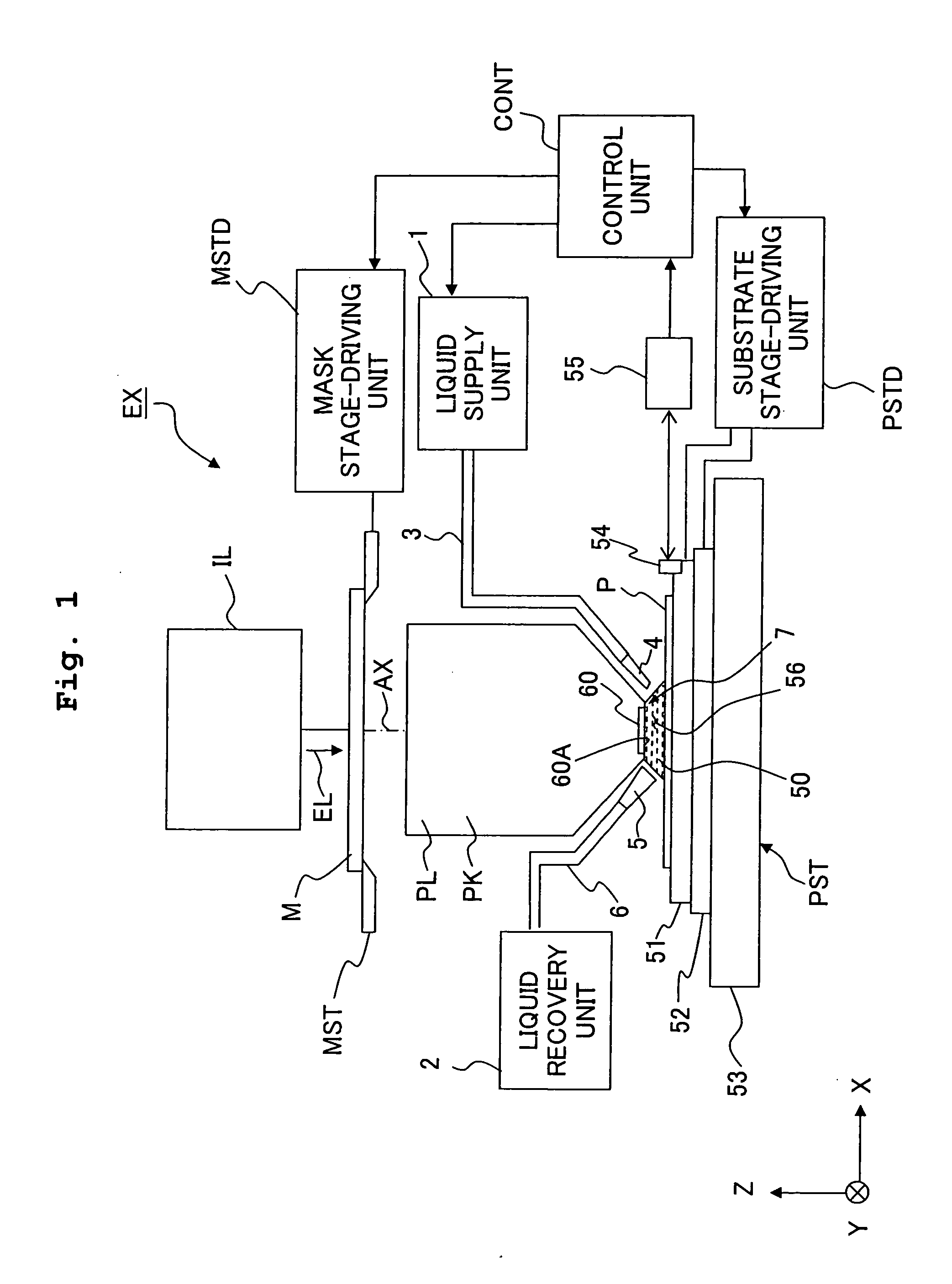

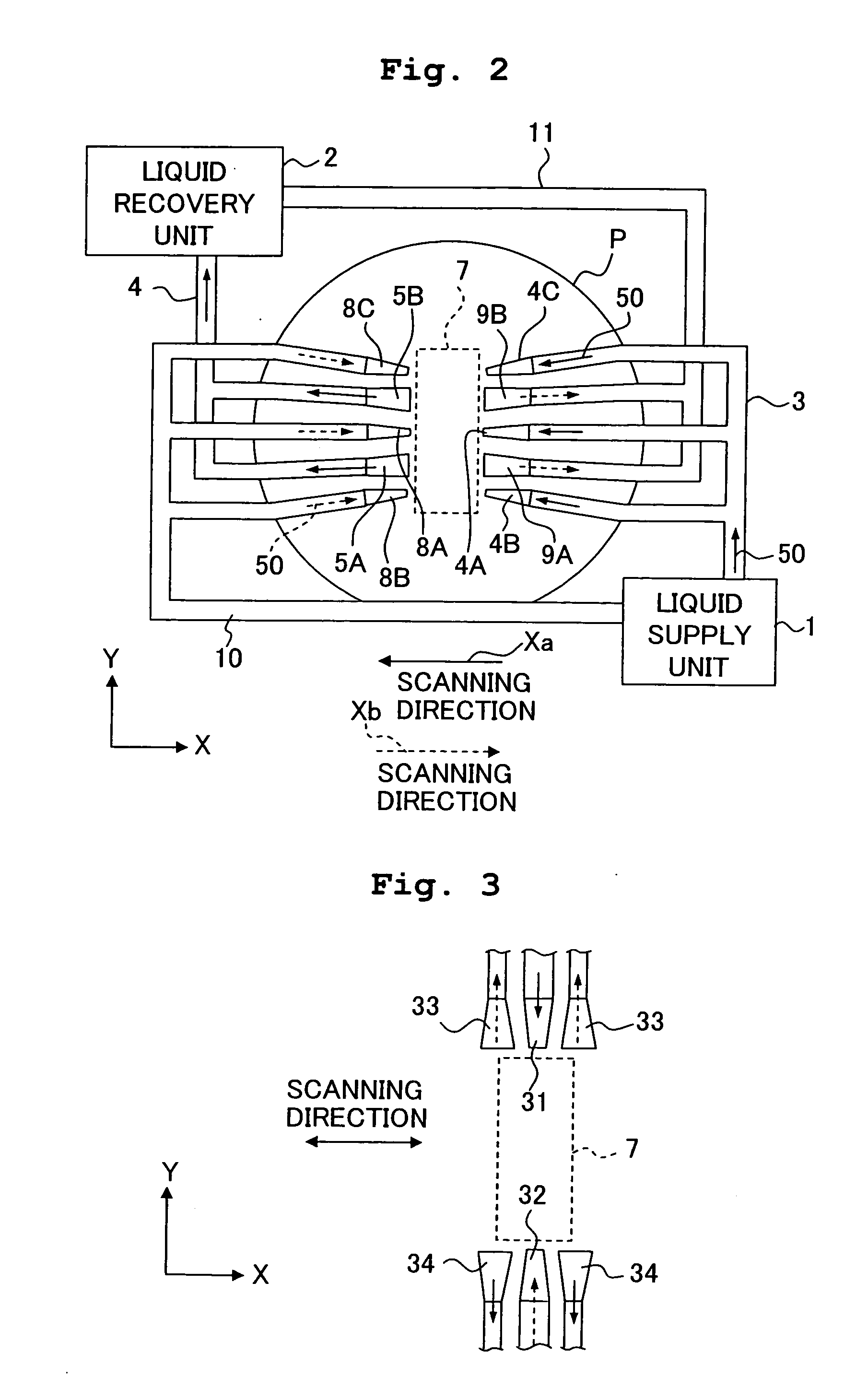

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0092] Next, an explanation will be made with reference to FIG. 7 about the present invention.

[0093] An exposure apparatus EX of this embodiment is designed such that the following conditional expression is satisfied provided that d represents a thickness of the liquid 50 between the lower surface 7A of the projection optical system PL and the surface of the substrate P (in this case, the spacing distance between the projection optical system PL and the substrate P), v represents a velocity of a flow of the liquid 50 between the projection optical system PL and the substrate P, ρ represents a density of the liquid 50, and μ represents a coefficient of viscosity of the liquid 50:

(v·d·ρ) / μ≦2,000 (3)

Accordingly, the liquid 50 flows as a laminar flow in the space 56. As for the liquid 50, it is also assumed that a plurality of different flow velocities v exist depending on the position in the liquid. However, it is enough that the maximum velocity Vmax thereof satisfies the expressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com