Semiconductor device and a method of manufacturing the same

a technology of semiconductor devices and semiconductors, applied in semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of reducing affecting the productivity of qfn, and affecting so as to improve the production yield of qfn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

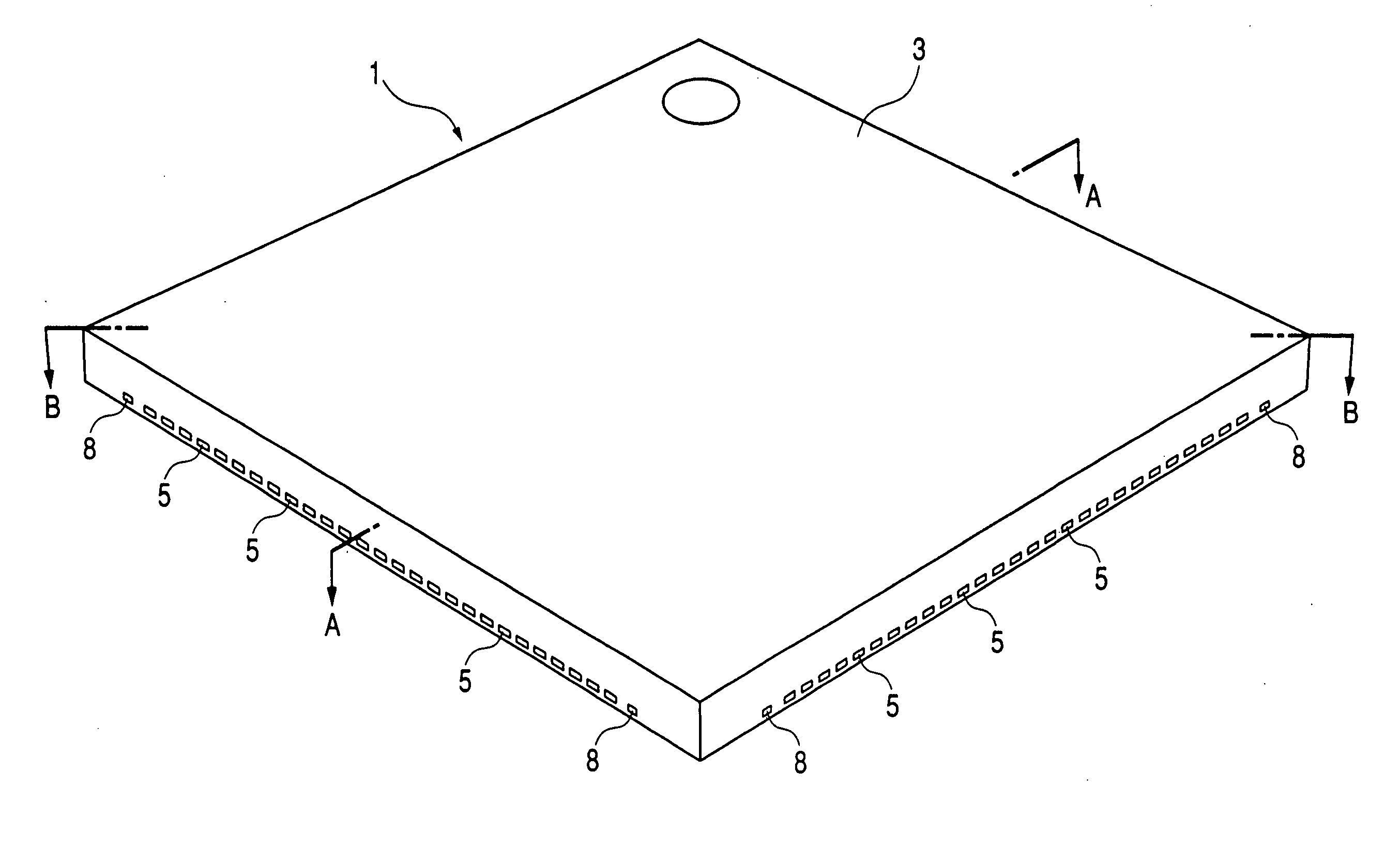

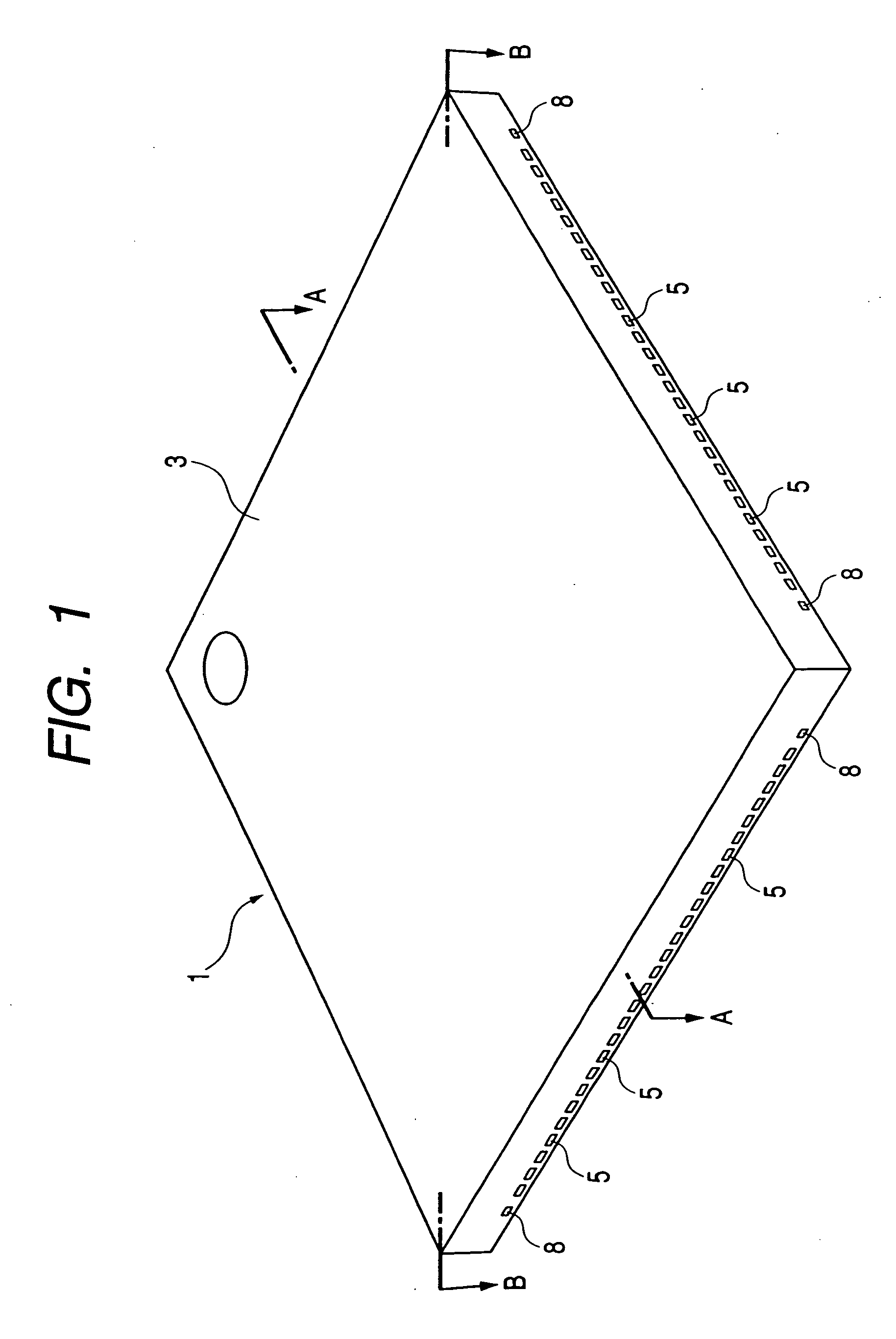

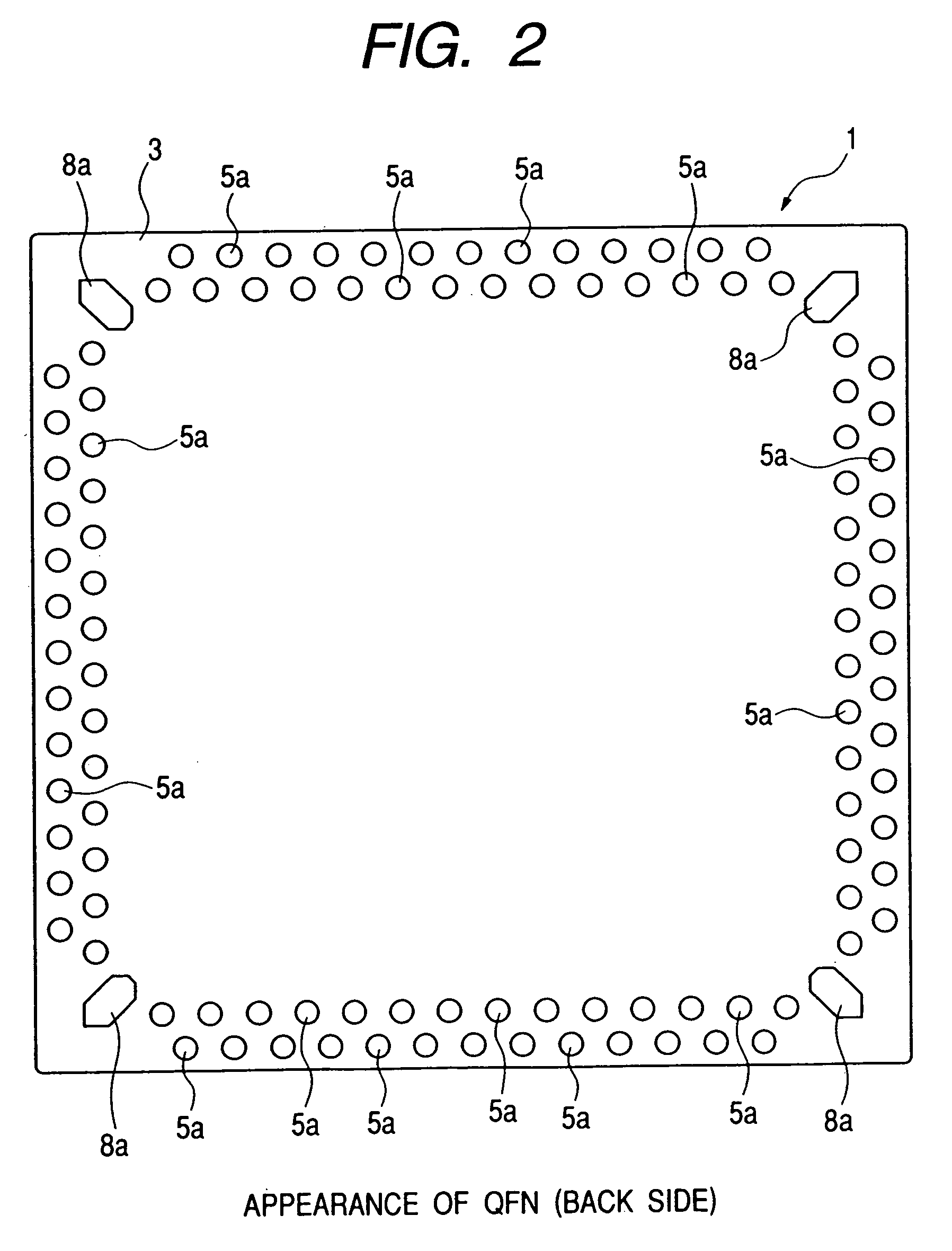

[0080]FIG. 1 is a perspective view showing an appearance of a QFN according to an embodiment of the present invention, FIG. 2 is a plan view showing an appearance (back surface) of the QFN, FIG. 3 is a plan view showing an internal structure (surface side) of the QFN, FIG. 4 is a plan view showing an internal structure (back surface) of the QFN, FIG. 5 is a side view of the QFN, FIG. 6 is a sectional view taken along line A-A in FIG. 1, and FIG. 7 is a sectional view taken along line B-B in FIG. 1.

[0081] The QFN of this embodiment, indicated at 1, is a surface-mounted type package wherein one semiconductor chip 2 is sealed with a resin sealing member 3. It external dimensions are, for example, 12 mm long, 12 mm wide, and 1.0 mm thick.

[0082] A semiconductor chip 2 is mounted on an upper surface of a metallic die pad portion 4 and in this state is disposed at a center of a resin sealing member 3. The die pad portion 4 is formed as a so-called small tab structure wh...

second embodiment

(Second Embodiment)

[0116]FIG. 35 is a plan view showing a part of the lead frame LF2 used in manufacturing the QFN 1, FIG. 36 is a sectional view taken along line Y-Y′ in FIG. 35, and FIG. 37 is a sectional view taken along line Z-Z′ in FIG. 35.

[0117] As shown in the figures, each of plural leads 5 formed in a lead frame LF2 used in this embodiment is different in thickness between inside (closer to a die pad portion 4) and outside of the portion where each of terminals 5a is formed. More specifically, in each lead 5, the thickness (t′) of an outside portion (FIG. 36) of the terminal 5a is larger than the thickness (t) of an inside portion (FIG. 37) of the terminal 5a (t′>t).

[0118] The lead frame LF2 is fabricated by the method of half-etching a metallic sheet 10 described in the previous first embodiment (see FIGS. 9 and 10), but a difference from the first embodiment resides in that, at the time of forming photoresist films 11 on one side of the lead-forming area of the metallic...

third embodiment

(Third Embodiment)

[0123]FIG. 44 is a plan view showing a part of a surface of a lead frame LF3 used in manufacturing QF1, FIG. 45 is a plan view showing a part of a back surface of the lead frame LF3, and FIG. 45 is a perspective view showing a central portion (the area where a die pad portion 4 is formed) on a larger scale.

[0124] The lead frame LF3 is characteristic in that plural projections 4a are formed along an outer periphery of a back surface of the die pad portion 4. As shown in FIG. 47, the projections 4a are formed simultaneously with forming patterns (die pad portion 4, leads 5, suspension leads 8) of the lead frame LF3. More specifically, there is provided a metallic sheet 10 of, for example, Cu, Cu alloy, or Fe—Ni alloy having a thickness of 125 to 150 μm, and one side of the metallic sheet 10 is coated with photoresist film 11 in portions where a die pad 4 and leads 5 (and suspension leads 8 not shown) are to be formed. In portions where terminals 5a and projections 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com