Double silver low-emissivity and solar control coatings

a technology of solar control and low emissivity, applied in the field of low emissivity coatings, can solve the problems thin transparent metal film of ag, unable to provide the extreme reflected color required for aesthetic and other reasons by certain applications, and achieves the effects of reducing visible transmission, reducing emissivity, and ensuring the appearance of the surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

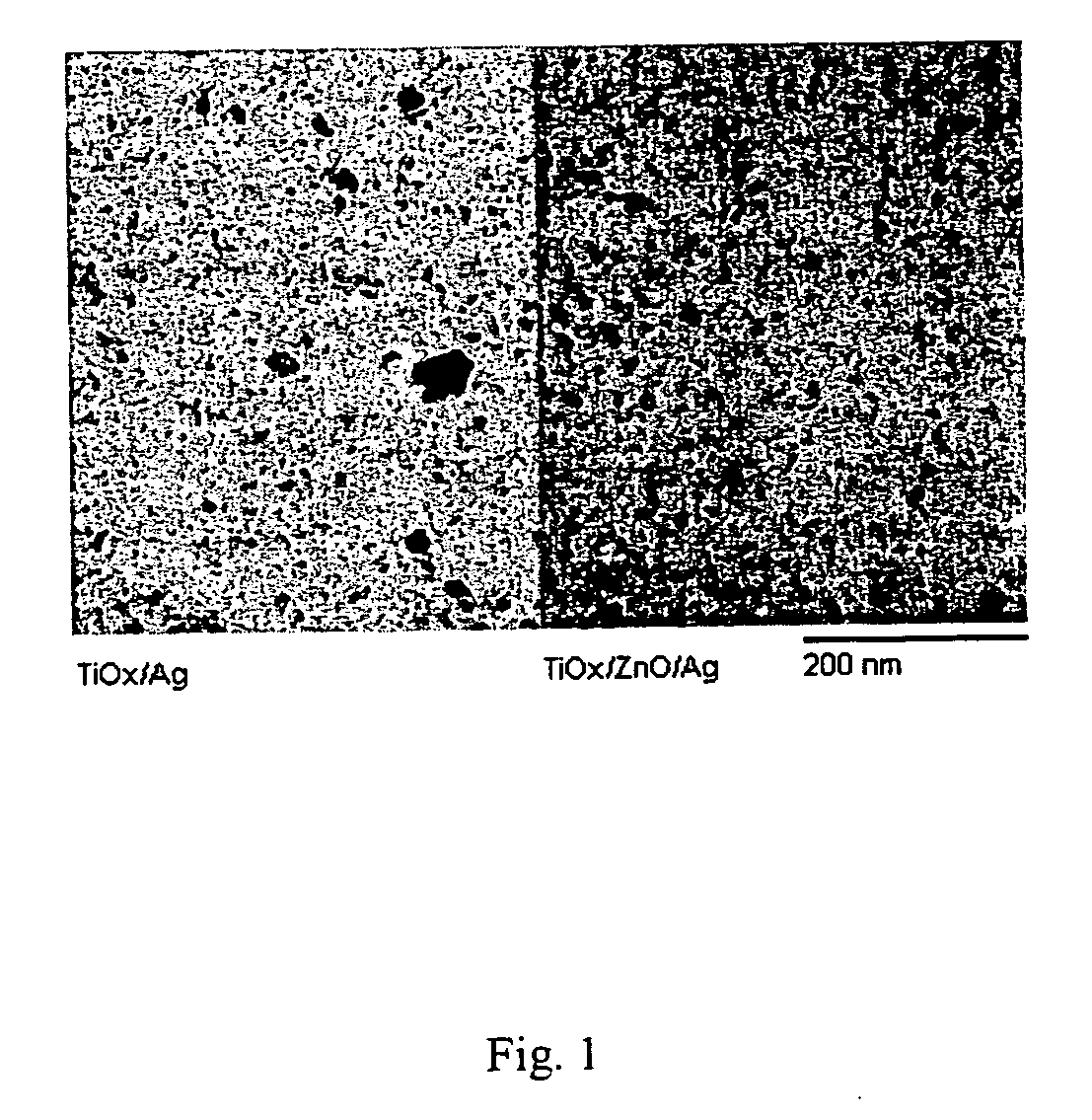

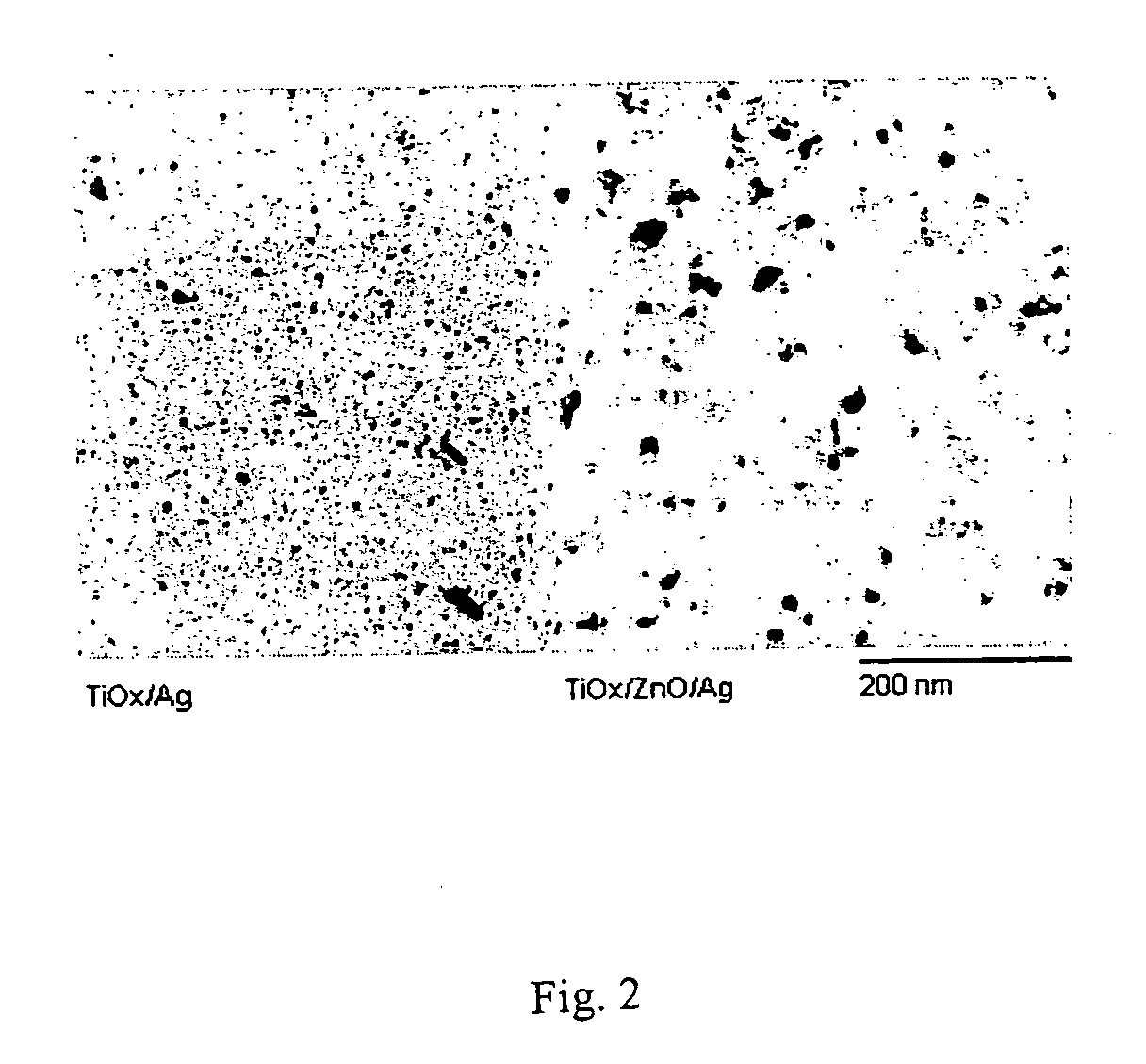

[0052] As discussed above, a sublayer of zinc oxide deposited on amorphous titanium oxide promotes the wetting of Ag on the zinc oxide and the formation of thinner layers of pin-hole free Ag.

[0053] To demonstrate this, Ag films 16 nm thick were planar DC magnetron sputter deposited onto amorphous TiOx (a-TiOx) underlayers 25 nm thick, and also onto ZnO (5 nm) / a-TiOx (25 nm) under(bi)layers. Transmission electron diffraction micrographs of the amorphous TiOx showed only broad diffuse rings, indicating that the TiOx was amorphous. The ZnO and a-TiOx dielectric layers were reactively sputtered from metal targets. The substrates for the a-TiOx layers included glass, and transmission electron microscopy (TEM) grids each having a 50 nm thick, amorphous, silicon nitride, electron transparent membrane peripherally supported by Si. The membrane was formed in a manner well known in the art by depositing silicon nitride by LPCVD (liquid phase chemical vapor deposition) onto a Si wafer, and th...

example 2

[0059] A complex structure incorporating many of the features of the present invention appears in Table 6.

TABLE 6LayerMaterial*5SiNx4c(2)NiCrOx4b(2)Ag4c(1)NiCrOx4b(1)Ag4aZnOx3cTiOx3bNiCrOx3aTiOx, SiNx, or superlattice2c(2)NiCrOx2b(2)Ag2c(1)NiCrOx2b(1)Ag2aZnOx1a(2)TiOx1bNiCrOx1a(1)TiOx, SiNx, or superlattice0glass substrate

*In Table 6, the subscript “x” indicates both stoichiometic and sub-stoichiometric compositions.

[0060] Various multilayer coatings including all, or a portion, of the layers shown in Table 6 were made by DC magnetron sputtering.

[0061] It was found that by varying the thicknesses of the silicon nitride and titanium oxide layers the reflected color of the coating can be positioned in any of the four color coordinate quadrants of the CEE 1976 L*a*b* (CIELAB) and CIE 1931 Yxy (Chromaticity) color spaces. Techniques and standards for quantifying the measurement of color are well known to the skilled artisan and will not be repeated here.

[0062]FIGS. 4a-4c show trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com