Image forming method, image formng apparatus, intermediate transfer body, method of modifying surface of intermediate transfer body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

I. First Embodiment

[0084] 1. Outline of Image Forming Device

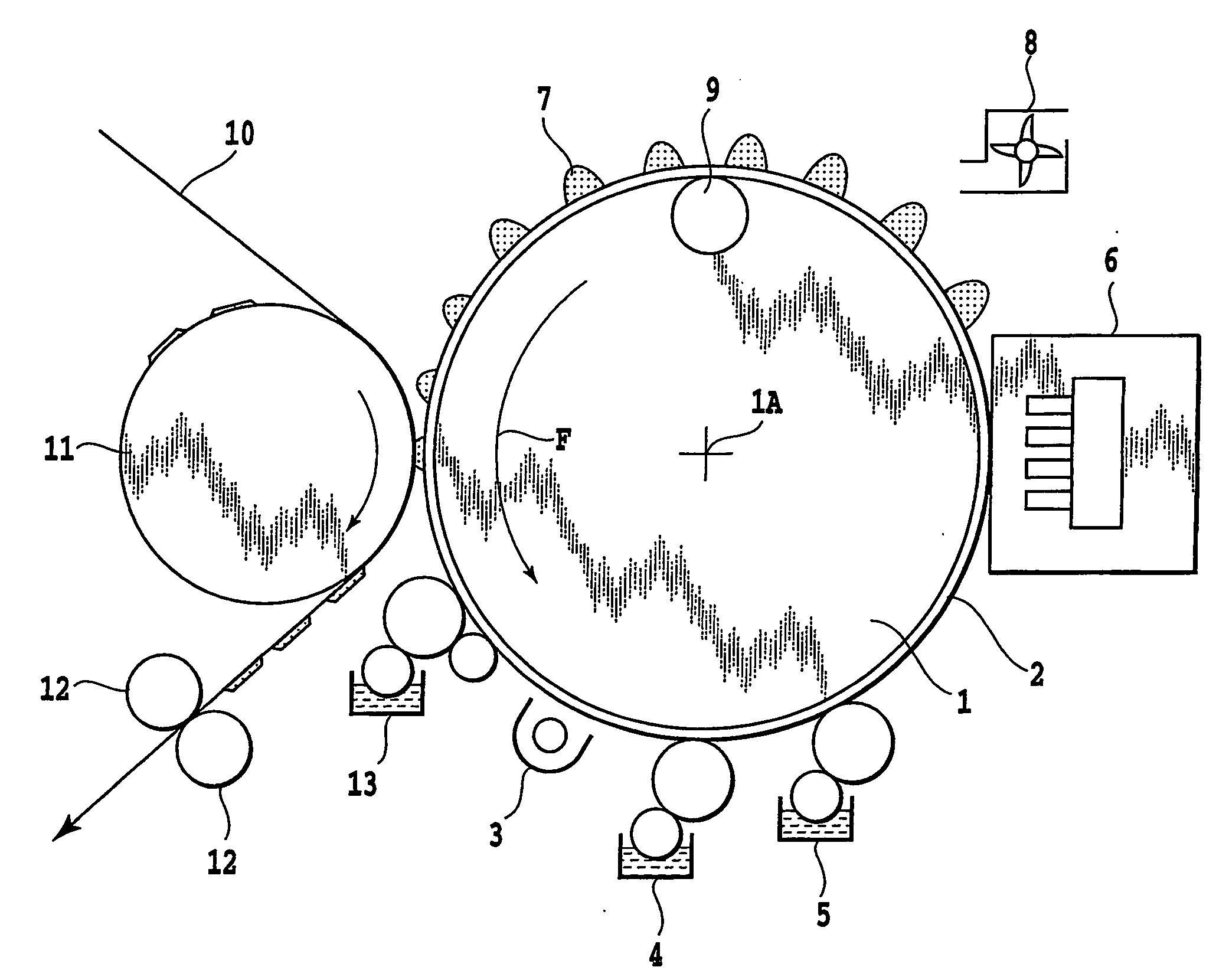

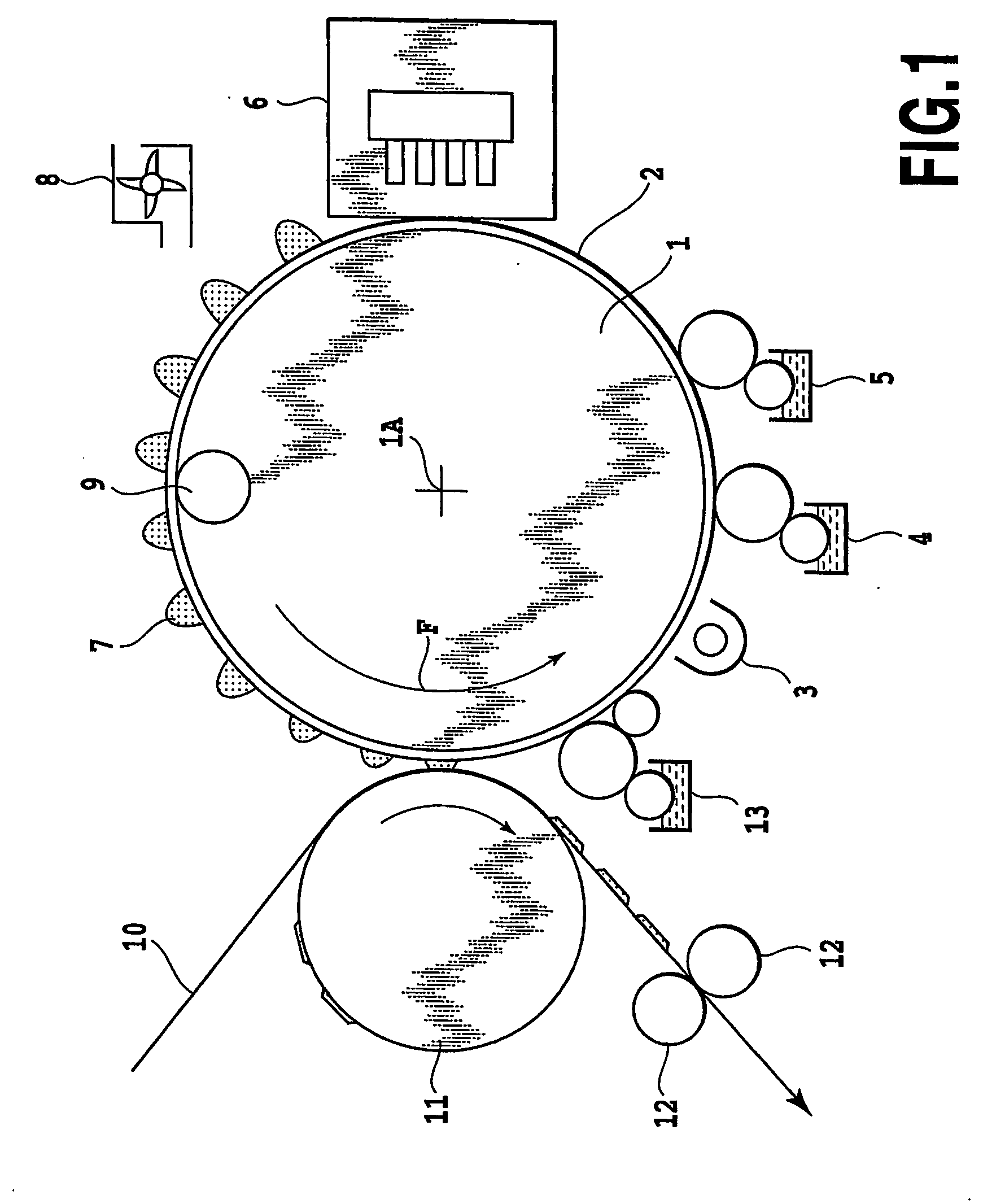

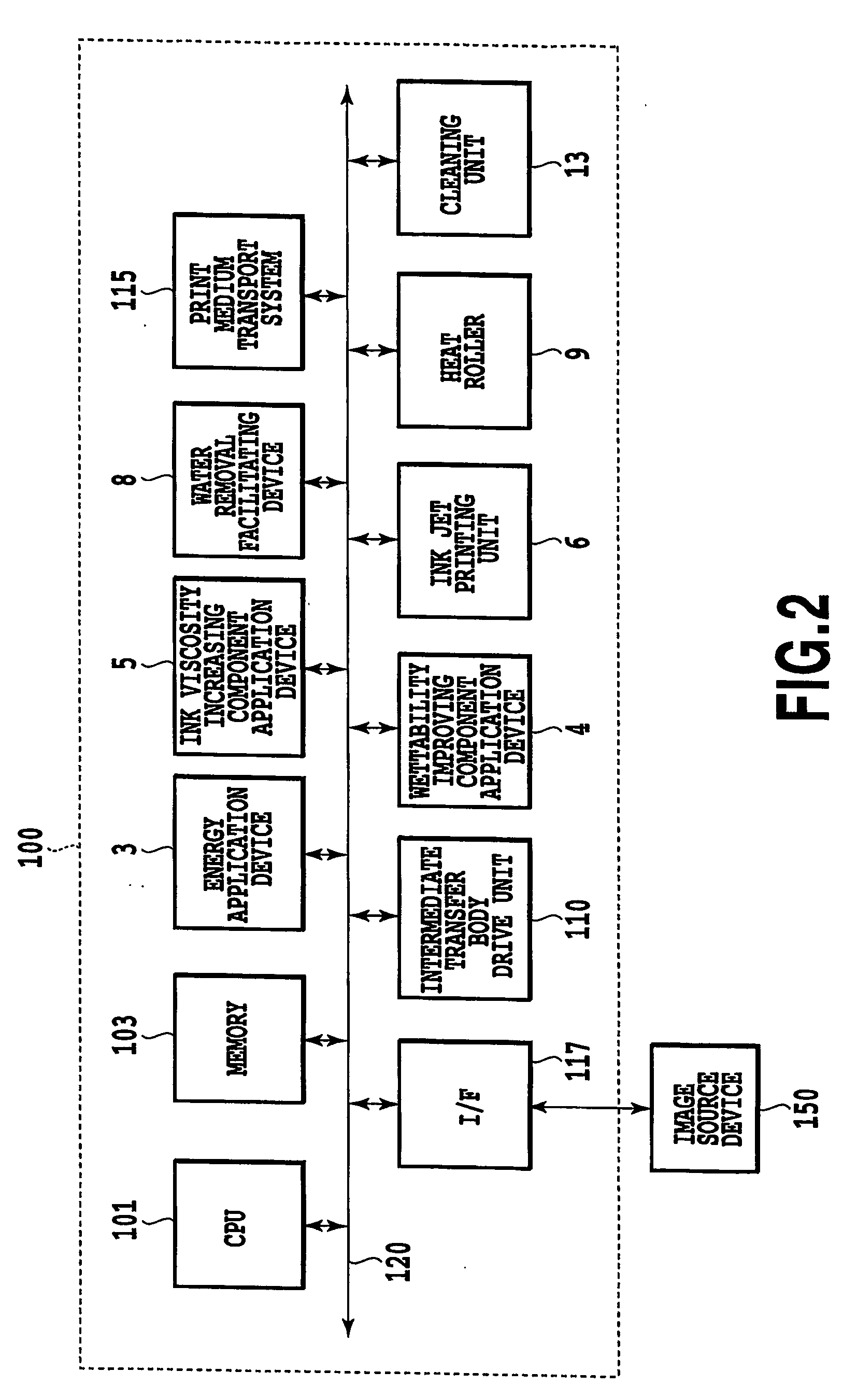

[0085]FIG. 1 is a schematic diagram showing an outline configuration of an image forming apparatus according to one embodiment of this invention. In FIG. 1, reference number 1 denotes an intermediate transfer body which is driven to rotate about an axis 1A in a direction of arrow F and has a surface layer 2 with good releasability. In FIG. 1, reference number 3 represents an energy application device that performs surface modifying processing on the surface layer 2. In the device shown in FIG. 1, application devices 4, 5 are put in contact with the surface of the intermediate transfer body 1 between the energy application device 3 and an ink jet printing unit 6 to apply a wettability improvement component and an ink viscosity increasing component to the surface. Although the application device 4 for applying a wettability improvement component such as surface active agent and the application device 5 for applying an ink vi...

embodiment 1

[0152] (a) Surface Modification of Transfer Body

[0153] As an intermediate transfer body this embodiment used an aluminum drum coated with silicone rubber with a hardness of 40 degrees (KE12 of Shinetsu Kagaku make) to a thickness of 0.2 mm. First, the surface of the intermediate transfer body was modified under the following conditions by using an atmospheric pressure plasma processor 3 (ST-7000 of Keyence make).

[0154] Irradiation distance: 5 mm

[0155] Plasma mode: High

[0156] Processing rate: 100 mm / sec

[0157] (b) Application of Ink Viscosity Increasing Component

[0158] Next, the intermediate transfer body whose surface was modified was coated with an ink viscosity increasing component using a roll coater. As the ink viscosity increasing component, a 10% by mass aluminum chloride hexahydrate solution in water was used.

[0159] (c) Forming of Image on Intermediate Transfer Body

[0160] Next, the ink jet printing unit (nozzle density: 1200 dpi (dots / inch), ejection volume: 4 pl, driv...

embodiment 2

[0169] (a) Surface Modification of Transfer Body

[0170] As an intermediate transfer body this embodiment used an aluminum drum coated with silicone rubber with a hardness of 60 degrees (KE30 of Shinetsu Kagaku make) to a thickness of 0.2 mm. First, the surface of the intermediate transfer body was modified under the following conditions by using an atmospheric pressure plasma processor (Plasma Atom Handy of Nippon Paint make).

[0171] Irradiation distance: Contact

[0172] Plasma mode: Standard

[0173] Processing rate: 10 mm / sec

[0174] (b) Application of Ink Viscosity Increasing Component

[0175] Next, 0.5% of fluorinated surfactant (Surflon S-141 of Seimi Chemical make) was added to a 10% by mass calcium chloride dihydrate solution in water, and this solution was coated to the surface of the intermediate transfer body whose surface was modified using the roll coater.

[0176] (c) Forming of Image on Intermediate Transfer Body

[0177] Next, the ink jet printing unit (nozzle density: 1200 dp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com