Method and apparatus for an exhaust emissions control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

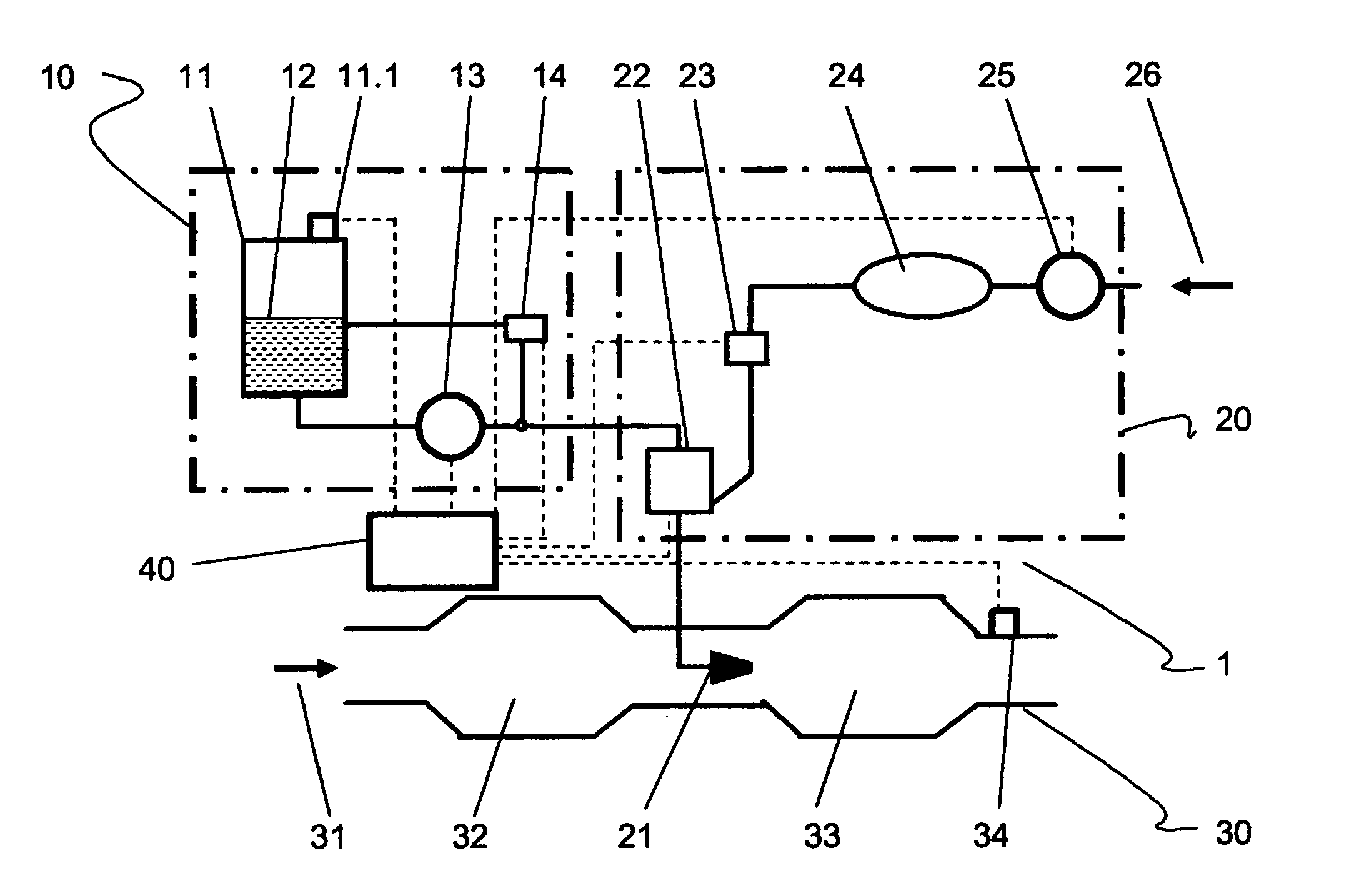

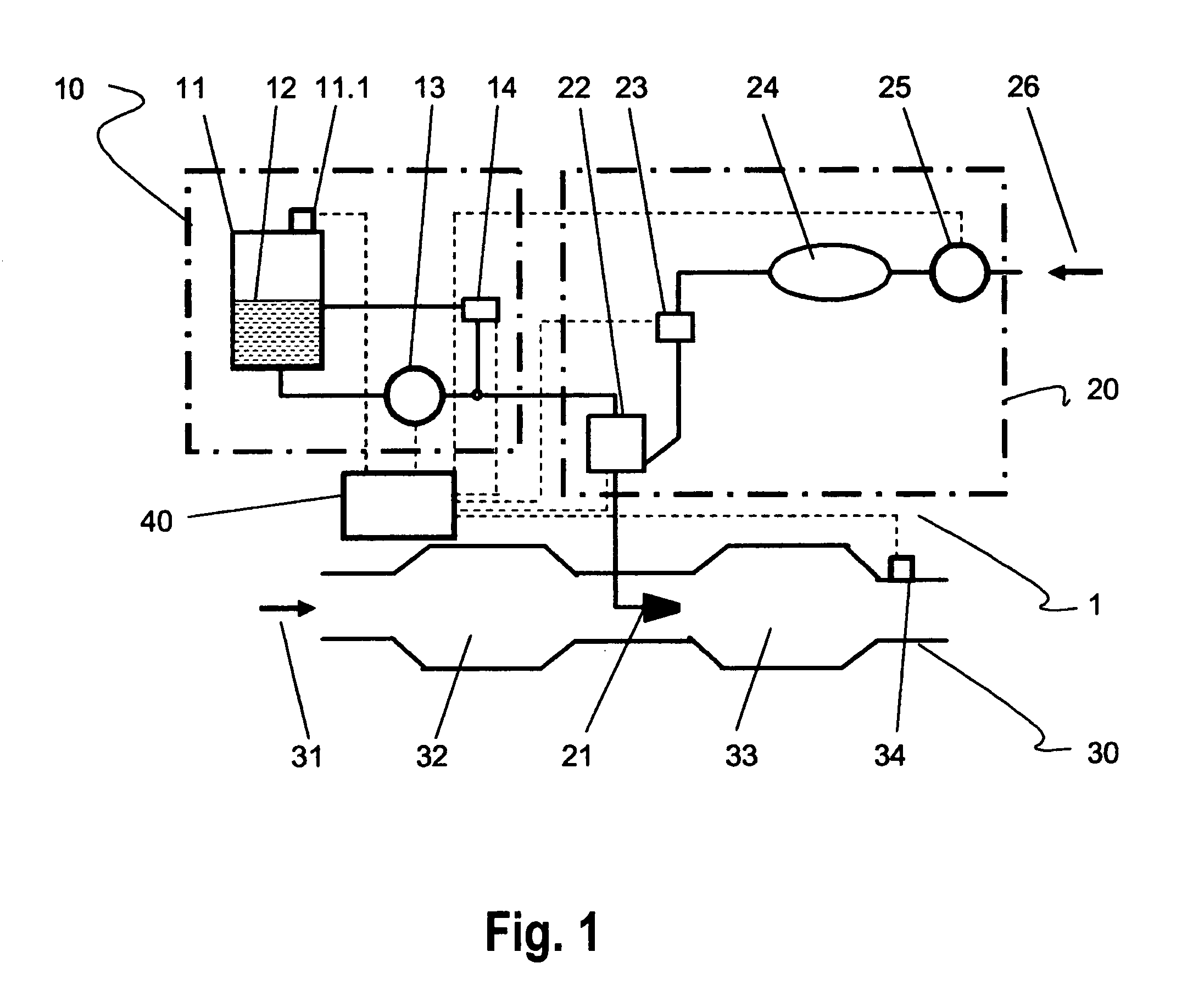

[0017]FIG. 1 shows a delivery module 10 and a metering module 20 of an exhaust emissions control system according to the existing art, having an exhaust gas conduit 30 and a control module 40.

[0018] Delivery module 10 is made up of a reservoir 11 that has a venting valve 11.1 and contains a uric acid solution (UWS) 12 which is conveyed via a delivery pump 13 to a metering valve 22. A pressure regulating valve 14 connected to the delivery side of pump 13 opens when the system pressure is too high, and then returns UWS to reservoir 11. In metering module 20, an air stream 26 is compressed with the aid of a pump 25, conveyed to a pressure accumulator 24, and conveyed via a regulating valve 23, together with the uric acid solution from delivery pump 13, to a metering valve 22. From there the air / UWS mixture is conveyed to an atomizer unit 21 disposed in exhaust gas conduit 30. In exhaust gas conduit 30, an exhaust gas stream 31 is conveyed in a first chamber to an oxidation catalytic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com