Method for manufacture of microcrystalline nitrocellulose

a technology of microcrystalline nitrocellulose and manufacturing method, which is applied in the direction of nitrocellulose explosive composition, explosives, weapons, etc., can solve the problems of difficult consolidation of nitrocellulose in this manner, low bulk density of cellulose, and light, fluffy material that is not easily compressed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following detailed description illustrates the invention by way of example and not by way of limitation. The description clearly enables one skilled in the art to make and use the invention, describes several embodiments, adaptations, variations, alternatives, and uses of the invention, including what is presently believed to be the best mode of carrying out the invention.

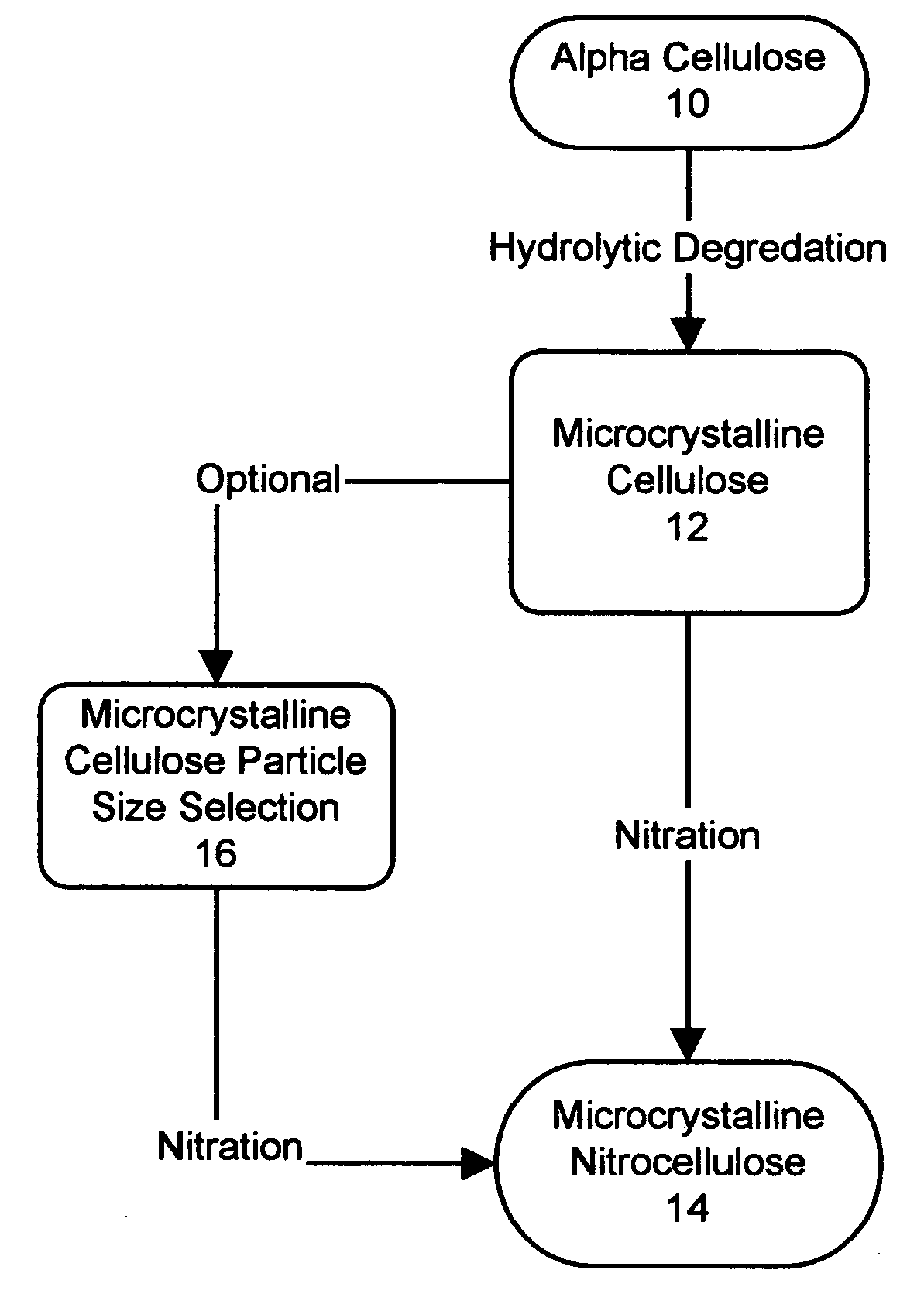

[0019] Microcrystalline cellulose is basically cellulose, and is derived from high-quality wood pulp, and in particular, from special grades of alpha cellulose. In many ways, cellulose is an ideal excipient. A naturally occurring polymer, cellulose is comprised of glucose units connected by a 1-4 beta glycosidic bond. These linear cellulose chains are bundled together as microfibril spiraled together in the walls of a plant cell. Each microfibril exhibits a high degree of three-dimensional internal bonding resulting in a crystalline structure that is insoluble in water and resistant to reagents. There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com