Exhaust gas purification system of an internal combustion engine and method for purifying the exhaust gases thereof

a technology of exhaust gas purification system and internal combustion engine, which is applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of insufficient activity of the known scr system at exhaust gas temperatures below approximately 250° c., and achieve the reduction of nox emissions, nox reduction, and nox reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

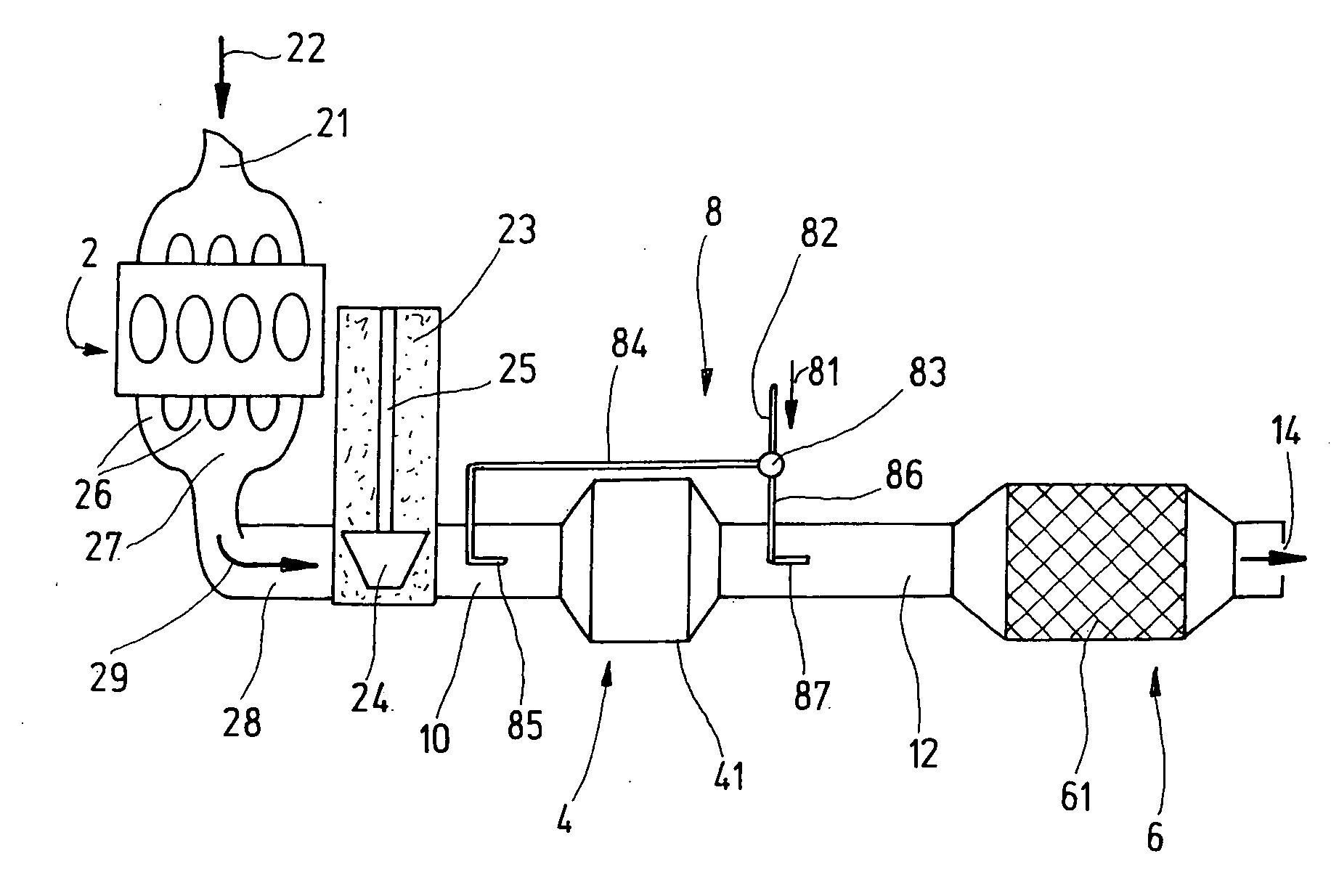

[0026]FIG. 1 shows an exhaust gas purification system according to the present invention. In FIG. 1, an oxidation catalytic converter 4 and a device for selective catalytic reduction, referred to as SCR catalytic converter 6, are disposed in an exhaust gas duct 28 of an internal combustion engine 2. Internal combustion engine 2 has an intake duct 21 for supplying fresh mixture 22, and outlet ducts 26 which are combined in a manifold 27 to form exhaust gas duct 28. Disposed in the exhaust gas duct is an exhaust gas turbine 24 of an exhaust gas turbocharger 23, which turbine 24 is coupled via a shaft 25 to a compressor, not shown here. Exhaust gas turbocharger 23 is optional and serves to improve the performance and exhaust gas emission characteristics of internal combustion engine 2.

[0027] Internal combustion engine 2 may be a diesel internal combustion engine featuring auto-ignition or a gasoline engine featuring direct fuel injection. Both types of engine emit a relatively oxygen-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com