Rolling/sliding part, rolling bearing, cam follower, and method of modificating surface of rolling/sliding part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

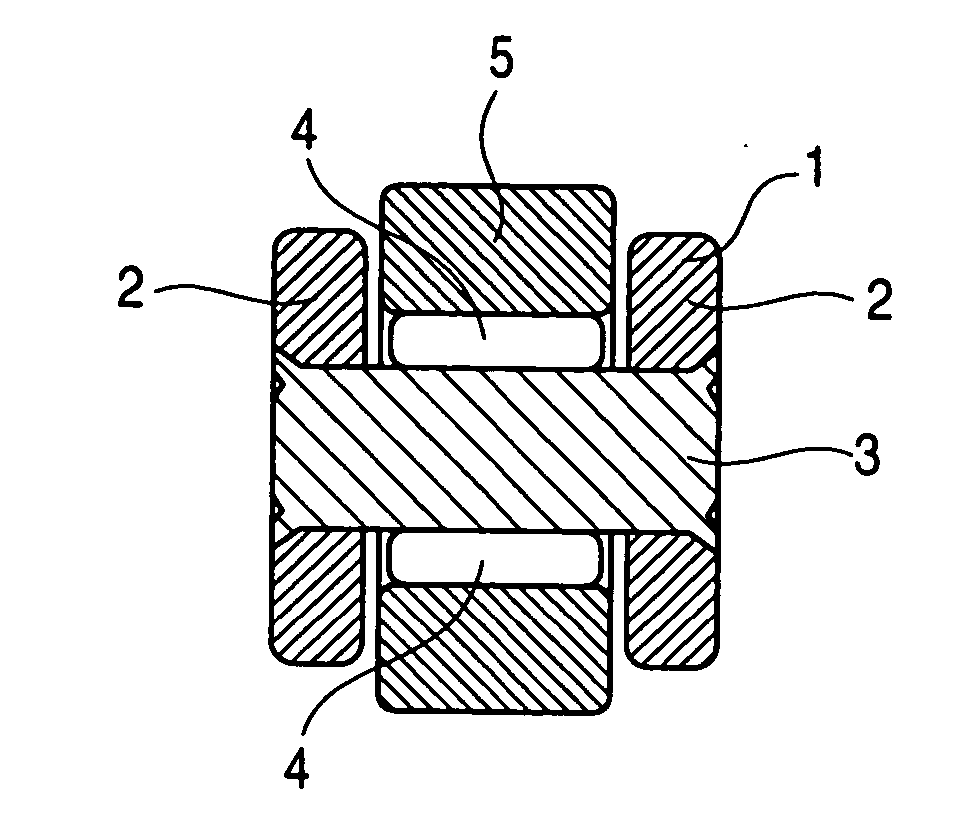

[0022]FIG. 1 is a sectional view of a cam follower according to Embodiment 1 of the present invention. In this cam follower, both ends of a shaft 3 is fixedly supported by a pair of support walls 2 and 2 which are provided with spacing between them at ends of the locker arm 1 which face a cam (not shown), a short cylindrical outer ring 5 is provided around the shaft 3 with rollers 4 and 4 disposed between the outer ring and the shaft, and the outside cylindrical surface of the outer ring 5 and the outside cylindrical surface of the cam is caused to abut on each other so that the outer ring 5 rotates about the shaft 3 with the rotation of the cam. Accordingly, the outer ring 5 corresponds to a rolling / sliding part of the present invention.

[0023] Now, considering that peeling occurring in the outside cylindrical surface of the outer ring 5 is surface peeling which is generated in a surface layer portion up to about 5 μm from a surface layer, the present inventors paid attention to im...

embodiment 2

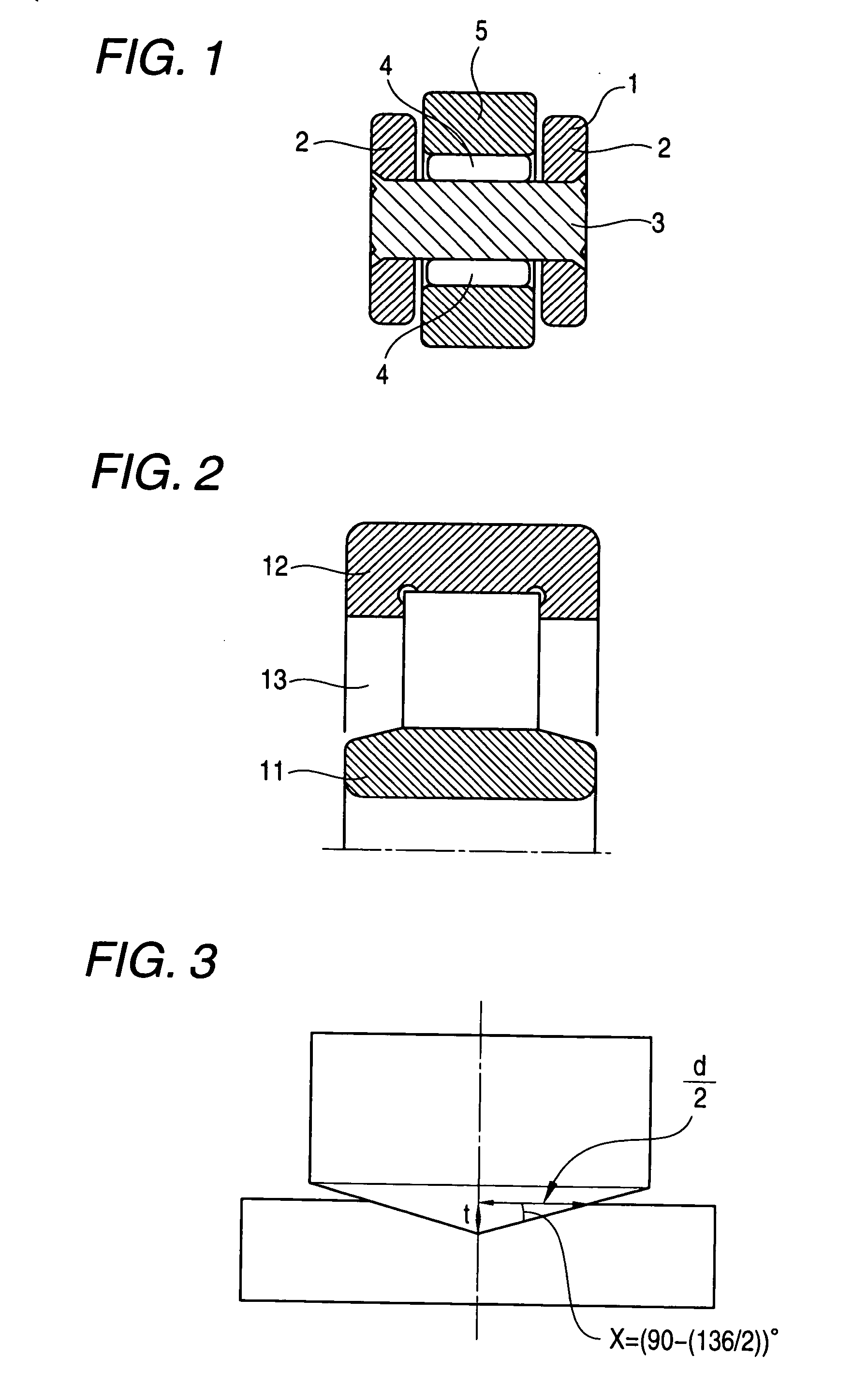

[0038] Although the outer ring 5 of the cam follower is exemplified in Embodiment 1 as a rolling / sliding part with its surface modification, which is used in a state where the rolling / sliding part comes into sliding contact or rolling contact with a mating part, the present invention can also be applied to a rolling bearing. FIG. 2 is a partial sectional view of the roller bearing according to Embodiment 2 of the present invention. This roller bearing is obtained by arranging rolling elements 13 that are a plurality of cylindrical rollers between an inner ring 11 and an outer ring 12 that are bearing rings. In such a cylindrical roller bearing, it is possible to obtain a roller bearing capable of preventing occurrence of peeling and occurrence of pitching to a mating member by subjecting the inner ring 11 and the rolling elements 13 to the surface modificating as described in Embodiment 1.

embodiment 3

[0039] The outer ring 5, the inner ring 11, and the rolling elements 13, and the like, which have the surface modificating characteristics as described above, are obtained by performing surface modificating on a surface layer portion of a base material to be a rolling / sliding part. Specifically, soft shot-blasting or flow barrel processing which has an effect on the hardness of only a surface layer portion existing at a depth of, at a maximum, 10 μm (preferably about 5 μm) from the surface of the base material is performed on the base material, and this processing is repeated until it is confirmed that, when Vickers hardness measurement is performed on the base material after the processing, the hardness A measured under a load of 0.1 N becomes Hv 780 to 900, and the hardness B measured under a load of 1 N becomes lower than the hardness A and less than Hv 780. Thereby, sliding parts having the surface modificating characteristics of Embodiment 1 can be obtained.

[0040] In the case ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com