Tooth and adaptor assembly for a dipper bucket

a technology of adaptor and dipper bucket, which is applied in the direction of soil shifting machines/dredgers, constructions, etc., can solve the problems of reducing the use time-consuming installation and removal of the locking pin, and directional stresses and shock loads at exceedingly high levels, so as to reduce the possibility of tooth and/or adaptor nose breakage, reduce the possibility of shock and bearing loads, and improve the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

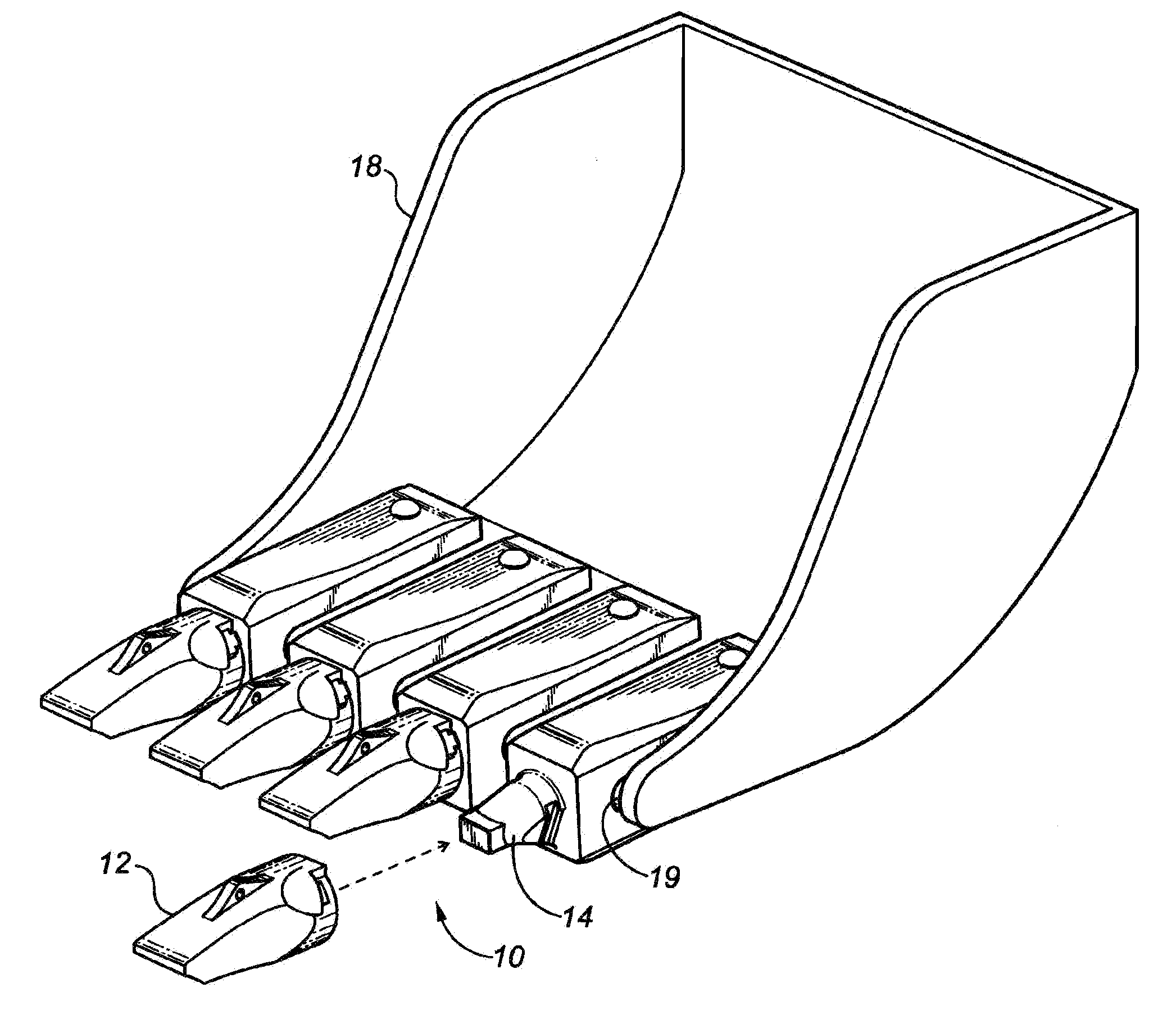

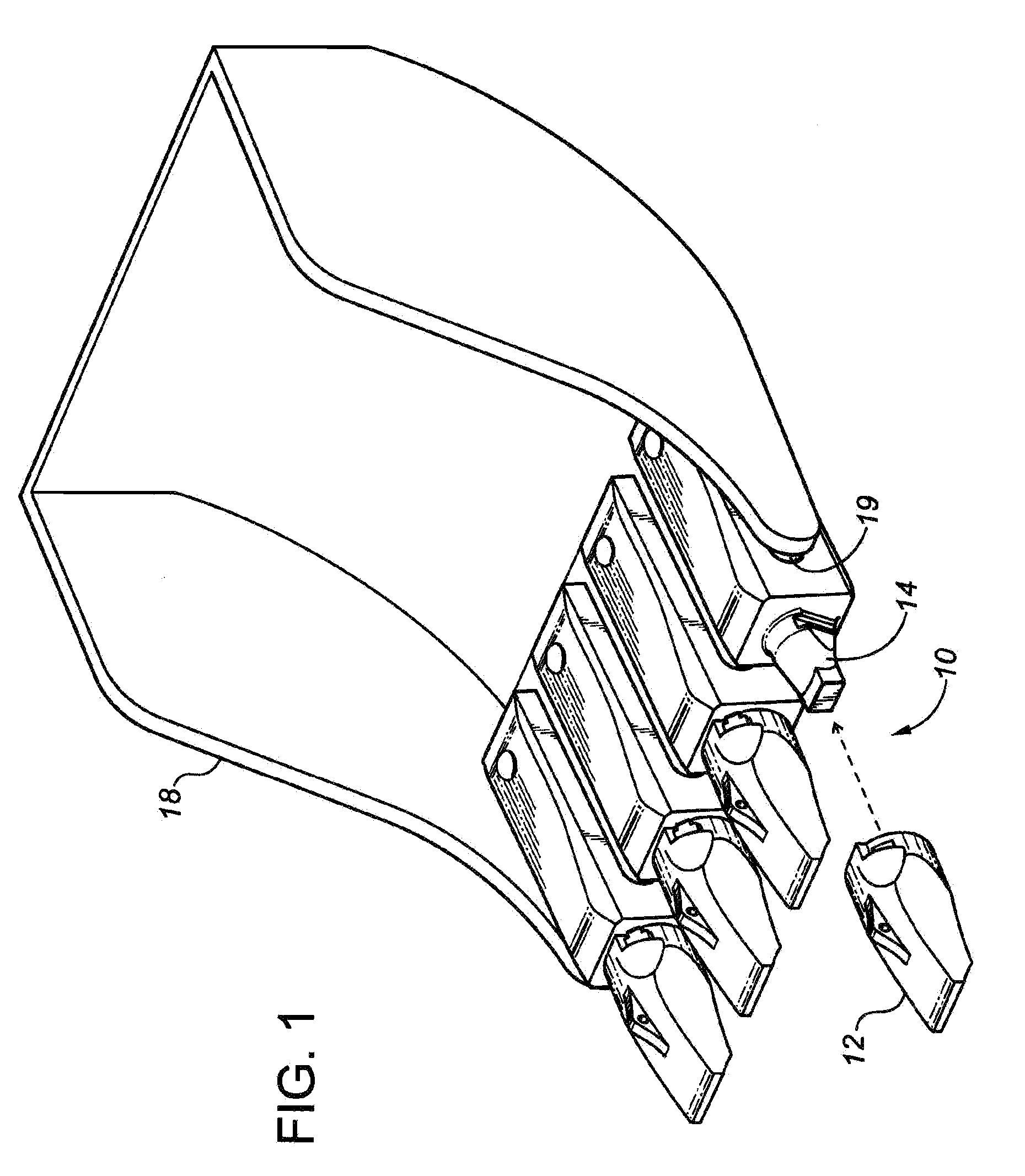

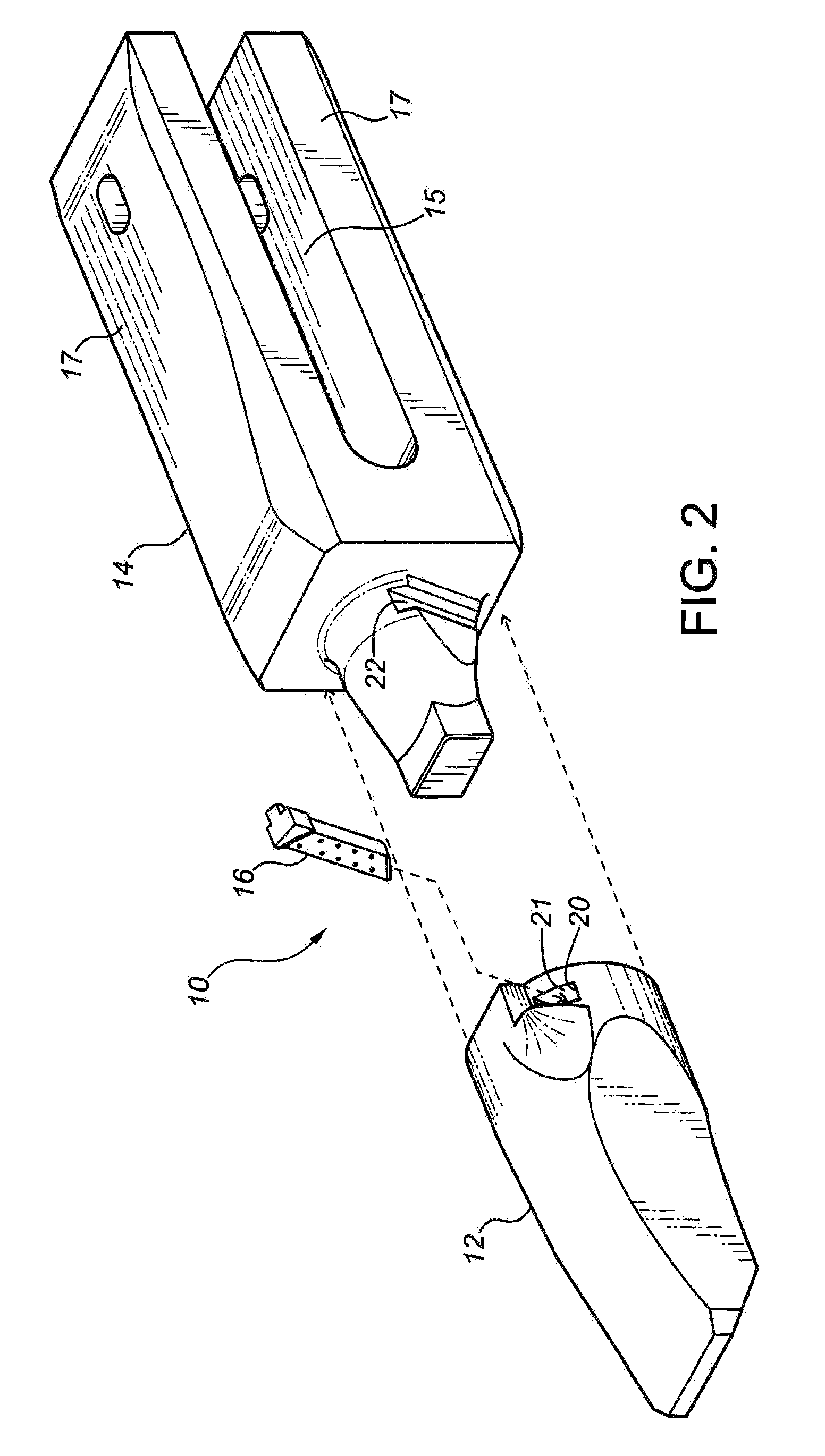

[0038] Referring to FIGS. 1 and 2, a representative embodiment of the present invention is shown. Tooth / adaptor assembly 10 broadly consists of excavation tooth 12, adaptor 14 and retainer pin 16. Adaptor 14 comprises an elongated U-shaped member that attaches to dipper bucket 18 on bucket lip 19 as well known to those skilled in the art. Tooth 12 is seated onto adaptor 14 and secured by retainer pin 16 that is inserted through opening 20 to fit snugly into groove 22. Tooth 12 is designed to bear the brunt of the wearing forces caused by excavating and will wear out over time. As tooth 12 wears out to the point that it is no longer serviceable, tooth 12 can be removed from adaptor 14 by extracting retainer pin 16 from opening 20 and sliding tooth 12 off of adaptor 14 so that a new tooth 12 may be installed.

[0039] Referring to FIGS. 3 and 4, side and top views of assembly 10 is shown with tooth 12 fully seated on adaptor 14. Tooth 12 has a pointed top 24 designed for excavating is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com