Method of evaluating elimination of microoganisms and apparatus for evaluating elimination of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

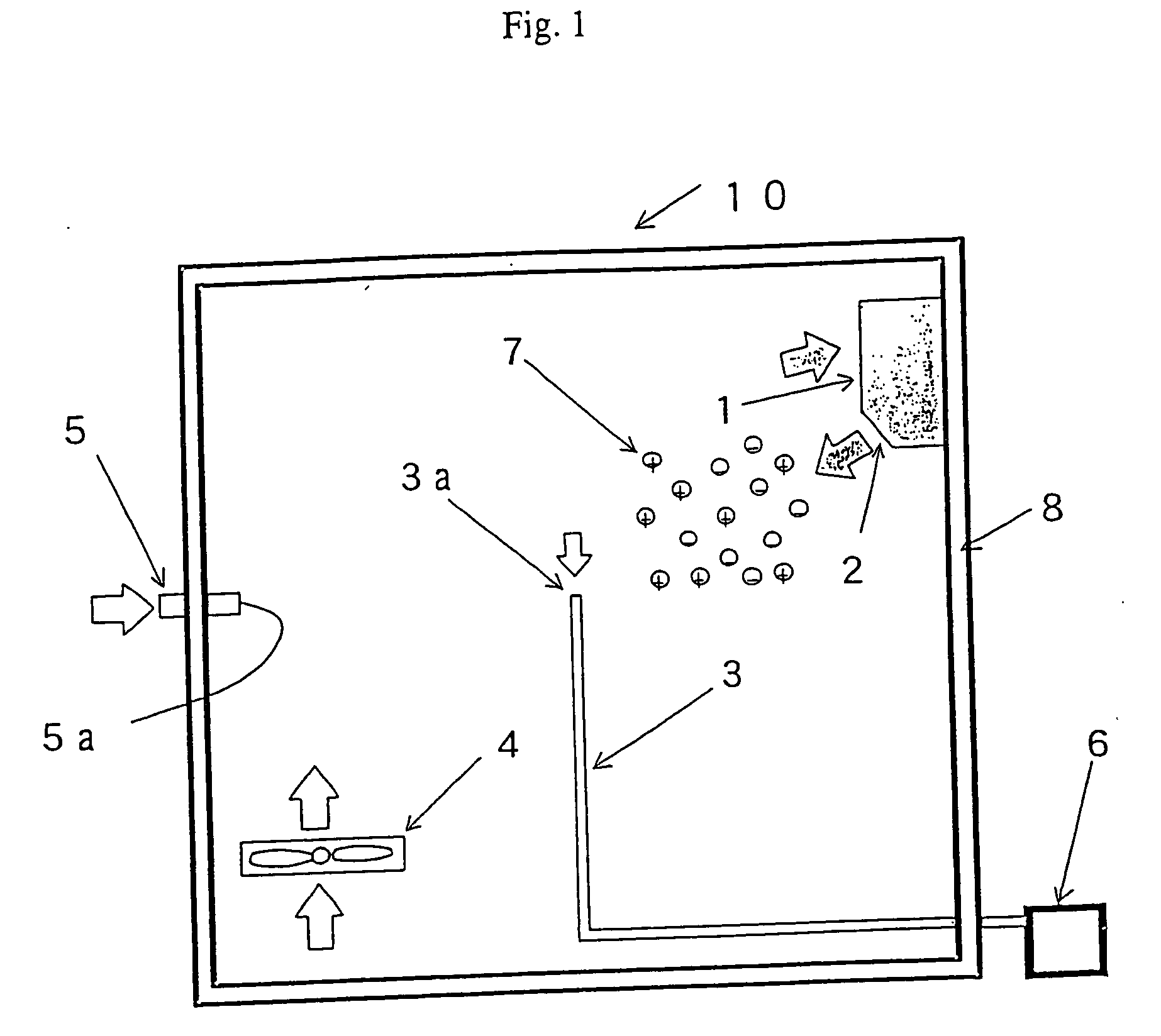

[0153] Example 2 was practiced under the following conditions. For evaluating the elimination microorganisms, the apparatus 10 for evaluating elimination of microorganism shown in FIG. 1 was used. The container 8 of the apparatus 10 for evaluating elimination of microorganism has a size for the inner space of 2.0 m length, 2.5 m width, and 2.7 m height.

[0154] Then, the atmosphere inside the container 8 was set to a temperature of 25° C. and a relative humidity of 42%. Further, the space inside the container 8 was stirred by the stirrer 4. Stirring was conducted by the stirrer 4 at an air flow of 4 m3 / min.

[0155]Escherichia coli were used as the microorganisms. The Escherichia coli in a mist were supplied into the container 8 via the microorganism injection port 5a. Then, Escherichia coli were scattered at a concentration of about 1,000 N / m3 in the container 8.

[0156] Further, the sampler 6 was constituted by using the Biotest Hyton RCS air sampler. The microorganisms were sampled a...

example 3

[0164] Example 3 was practiced under the following conditions. For evaluating the evaluation of microorganisms, the apparatus 10 for evaluating elimination of microorganism shown in FIG. 1 was used. The container 8 of the apparatus 10 for evaluating elimination of microorganisms has a size for the inner space of 2.0 m length, 2.5 m width and 2.7 m height. Then, the atmosphere inside the container 8 was set to a temperature of 25° C. and a relative humidity of 42%.

[0165] Further, in Example 3, comparison was made for the case of stirring and for the case of not stirring the inside of the container 8 which will be described later, and the stirring was conducted by the stirrer 4 at an air flow of 4 m3 / min in the case of stirring the space inside the container 8.

[0166]Cladosporium, a kind of mycete, were used as microorganisms. Cladosporium were supplied into the container 8 as a mist via the microorganism injection port 5a. Then, Cladosporium were scattered at a concentration of abou...

example 4

[0172] Example 4 was practiced under the following conditions. For evaluating the elimination of microorganisms, the apparatus 10 for evaluating elimination of microorganism shown in FIG. 1 was used. The container 8 of the apparatus 10 for evaluating elimination of microorganism has a size for the inner space of 2.0 m length, 2.5 m width and 2.7 m height.

[0173] Then, the atmosphere inside the container 8 was set to a temperature of 25° C. and a relative humidity of 42%. Further, space in the container was stirred by the stirrer 4. Stirring was conducted by the stirrer 4 at an air flow of 4 m3 / min.

[0174]Cladosporium, a kind of mycete, were used as microorganisms. Cladosporium were supplied into the container 8 in a mist form via the microorganism injection port 5a. Then, Cladosporium were scattered at a concentration of about 1,000 N / m3 in the container 8.

[0175] Further, the sampler 6 was constituted by using the Biotest Hyton RCS air sampler. The microorganisms were sampled at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com