High strength, high toughness, weldable, ballistic quality, castable aluminum alloy, heat treatment for same and articles produced from same

a technology of aluminum alloy and casting alloy, which is applied in the field of aluminum alloy casting operations, can solve the problems of not having the desirable combination of high strength, high ductility, hot tearing, and unusability of the cast produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

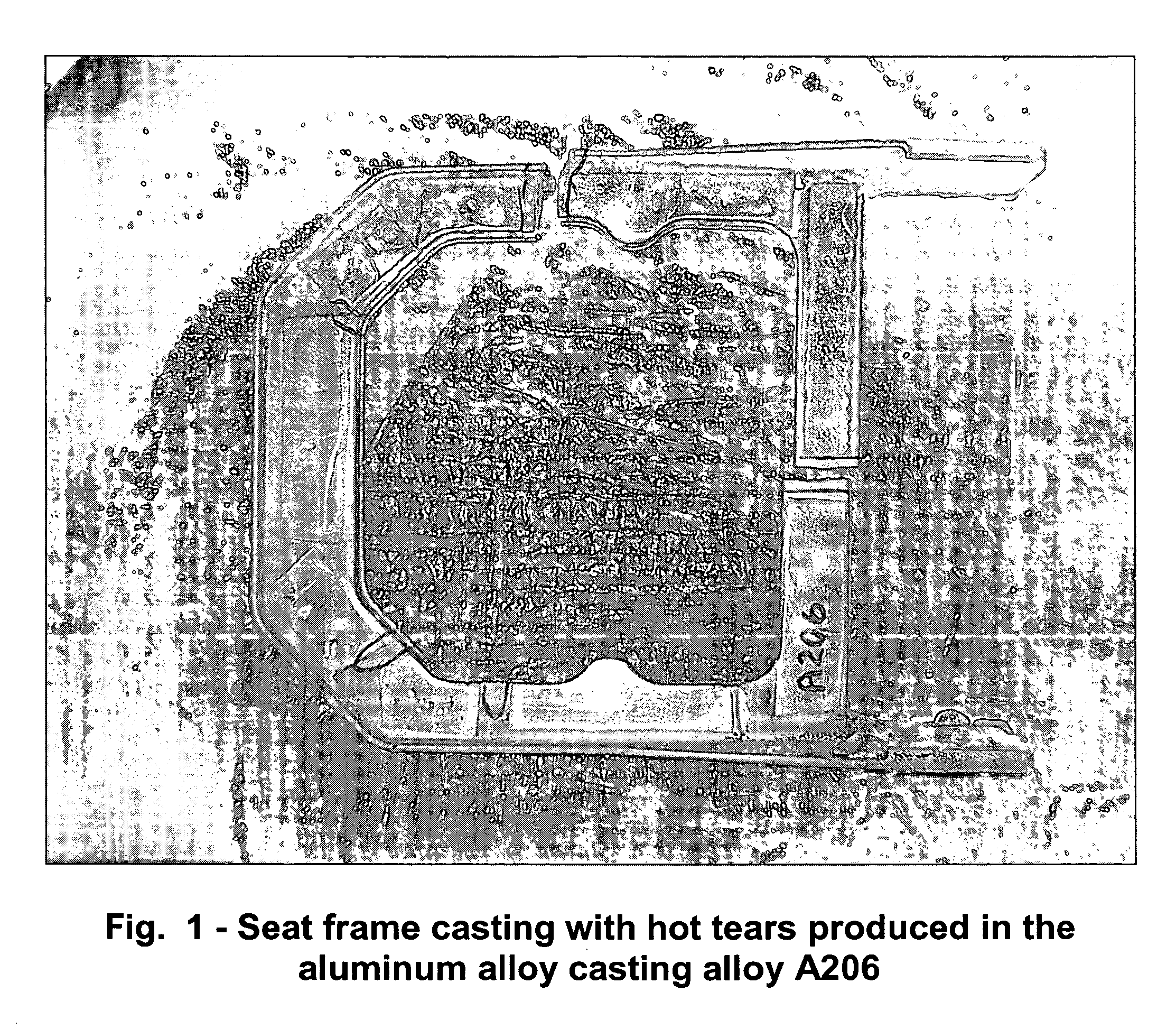

Problems solved by technology

Method used

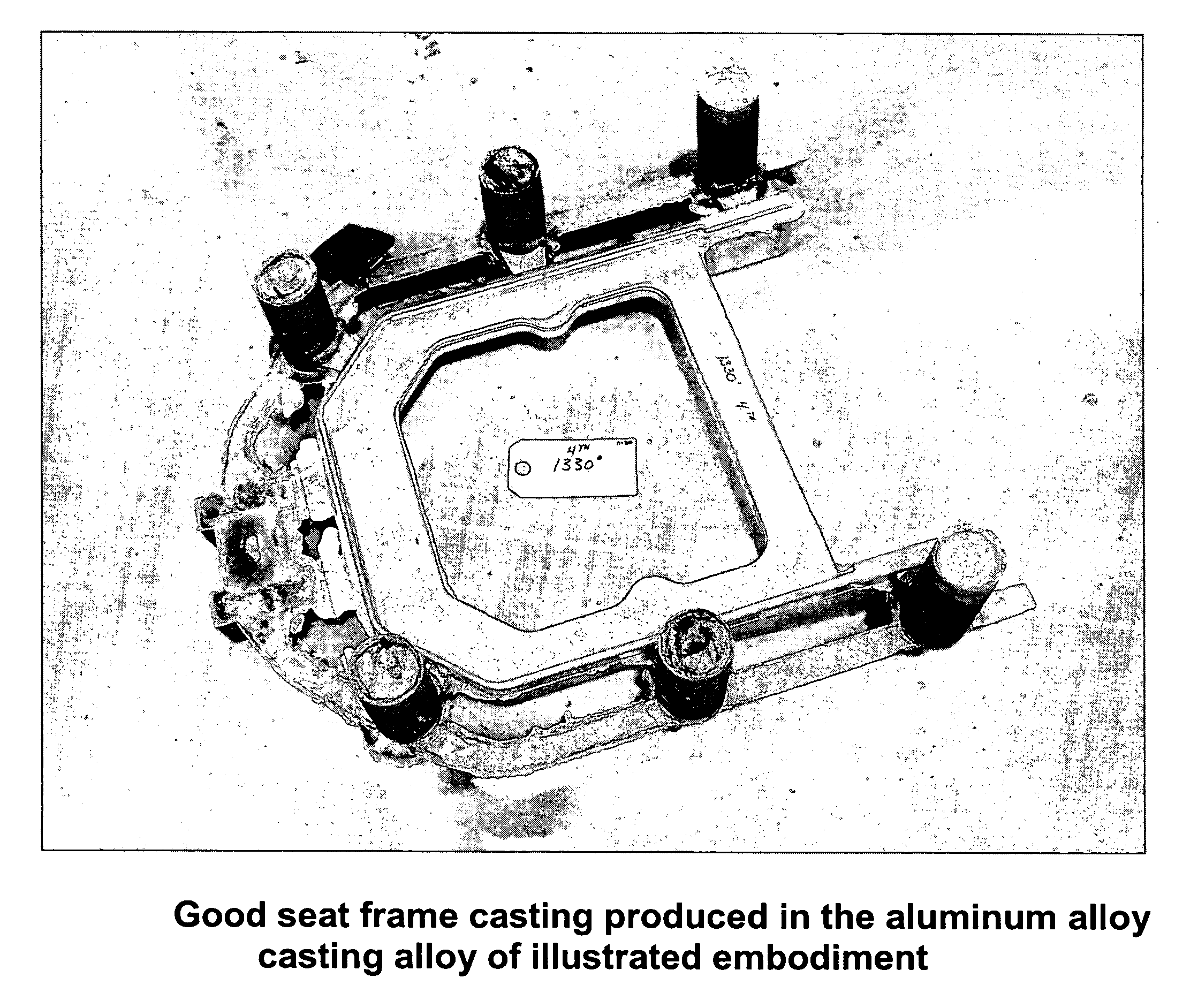

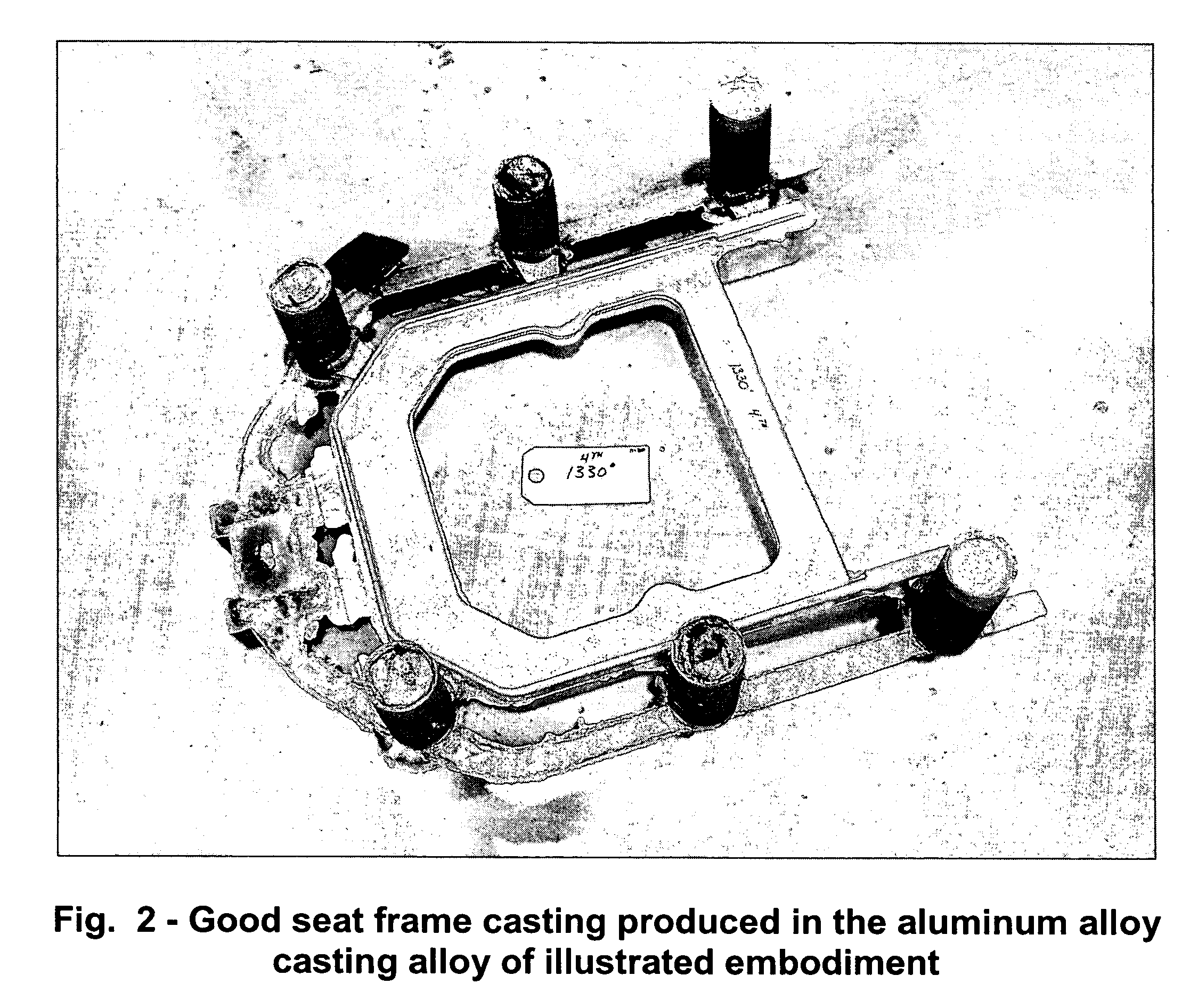

Image

Examples

Embodiment Construction

[0032] Aluminum alloy casting alloys A201 and A206 were purchased as ingots from a supplier. The aluminum alloy casting alloy in the illustrated embodiment was produced using A206 ingot with addition of aluminum-copper, aluminum-manganese, aluminum-chromium, aluminum-vanadium, aluminum-zirconium master alloys and pure magnesium. Commercially available aluminum-titanium-boron and aluminum-titanium-carbon grain refiners were used. The chemical compositions of a plurality of aluminum alloy casting alloys produced are shown in Table 7. In Table 7, the columns represent a weight percentage of the indicated element and each row represents one mixture of the constituent elements, termed a heat and designated by a letter A through W.

TABLE 7Chemical compositions of aluminum alloy casting alloysAmount in weight percentHeat IDCuCrMgMnVZrTiFeSiotherAlA5.600.260.290.140.230.370.030.08remB6.080.180.230.290.130.220.200.030.11remC4.500.010.260.400.120.150.190.040.04remD5.200.010.240.400.110.140.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| mechanical property | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com