Materials and Methods For the Purification of Polyelectrolytes, Particularly Nucleic Acids

a technology of polyelectrolytes and materials, applied in the preparation of sugar derivatives, chemical/physical processes, peptides, etc., can solve the problems of additional implementation and neutralization of reagents, and achieve the effect of purifying polyelectrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

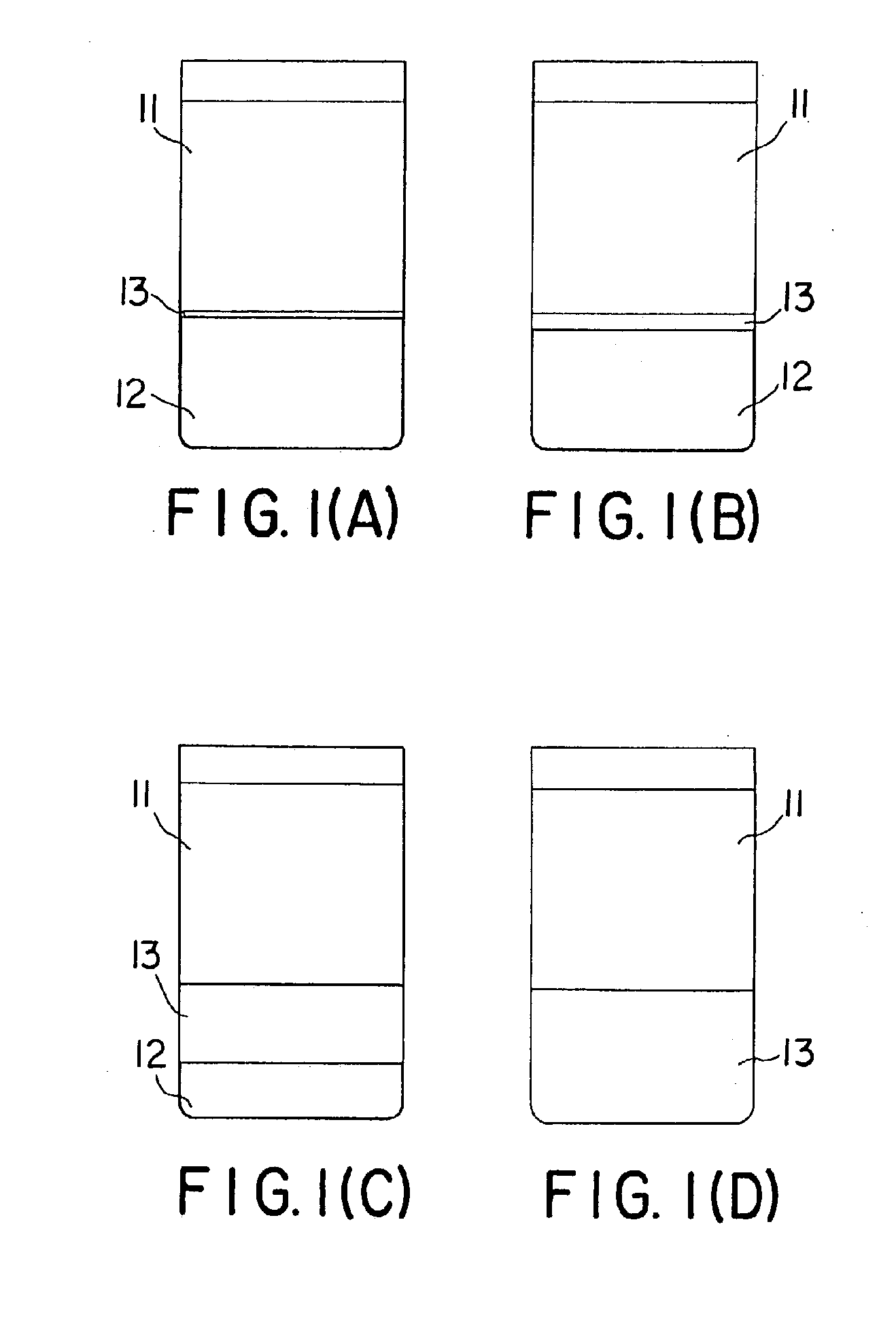

example 1

[0047] 25 grams of agarose (Sigma Chemical Co., St. Louis, Mo., product number A9918) were dissolved in one liter of 8M urea solution by heating the solution with stirring until the solution became clear, forming layer 12, in FIG. 1. The medium is made by slowly adding water, 11, on top of a 2.5% (W / V) agarose solution in 8M urea, 12. A thin layer of gel, 13, which forms at the interface of the agarose and water layers, grows in thickness until all the agarose gels as time progresses from FIG. 1(A) to FIG. 1(D), and as described in Example 1. This solution remained ungelled after cooling to room temperature for a period of over 150 days. Upon slow addition of water, layer 11 in FIG. 1, to the top of this solution and standing unperturbed for a few hours, a gelled layer, 13, forms at the interface. This is indicated by the appearance of a white color. This layer plays an important role in preventing further mixing of the water with the agarose in the chaotropic solution. Water and ur...

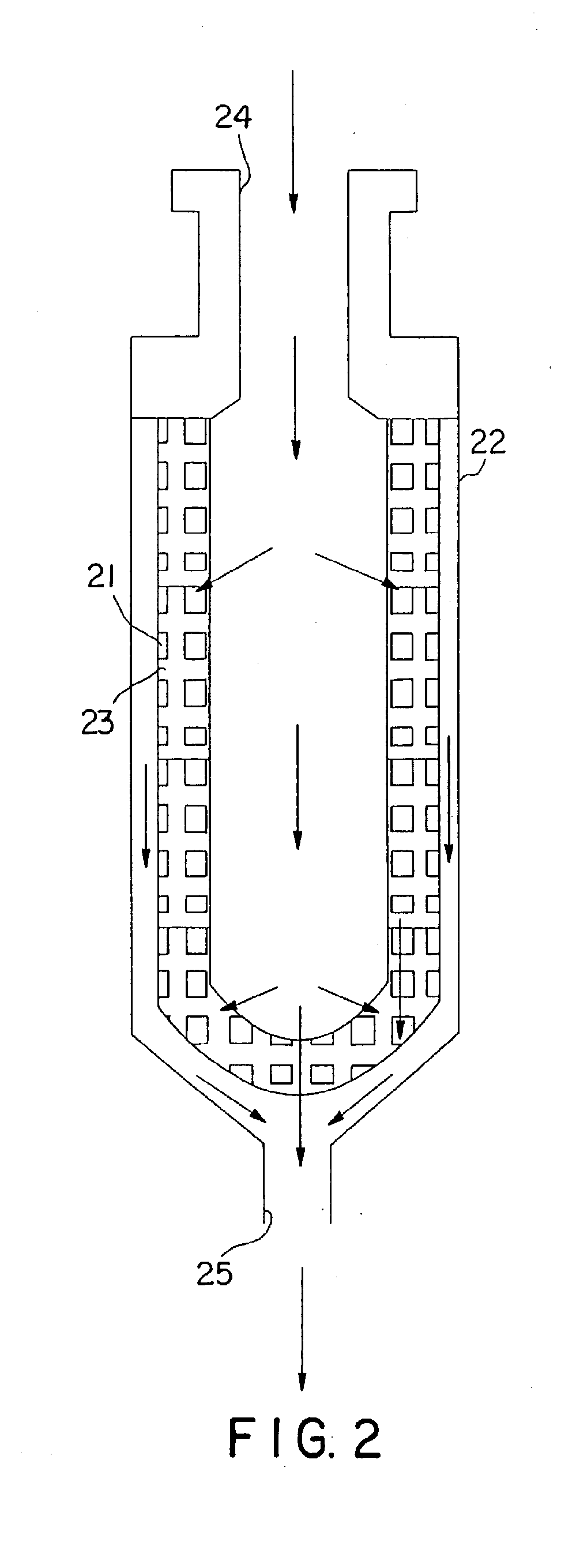

example 2

[0048] An ultra high molecular weight polyethylene (UHMWPE) porous cylinder, 9.5 mm O.D., 4.8 mm I.D., and 35 mm long was used, with one end sealed and the other open. This cylinder had nominal pore size of 20 microns and void volume (empty space in the walls of the cylinder) of approximately 50%. The inner bore of the cylinder was blocked by a rod of the same diameter as the ID of the cylinder to prevent the agarose solution from filling the bore. Agarose (2.5% w / v) was solubilized in 8M Urea as in Example 1. The agarose solution was vacuum drawn into the pores of the cylinder using a vacuum pump. The cylinder was soaked in water overnight. Referring to the schematic in FIG. 2, this cylinder is numbered 21. The agarose gelled in the pores of the cylinder as the urea diffused out to form the gel, 23. The rod was removed from the cylinder. A luer fitting attachment, 24, was sealed to the open end of the cylinder, and was used to attach the device to syringes or peristaltic pumps for ...

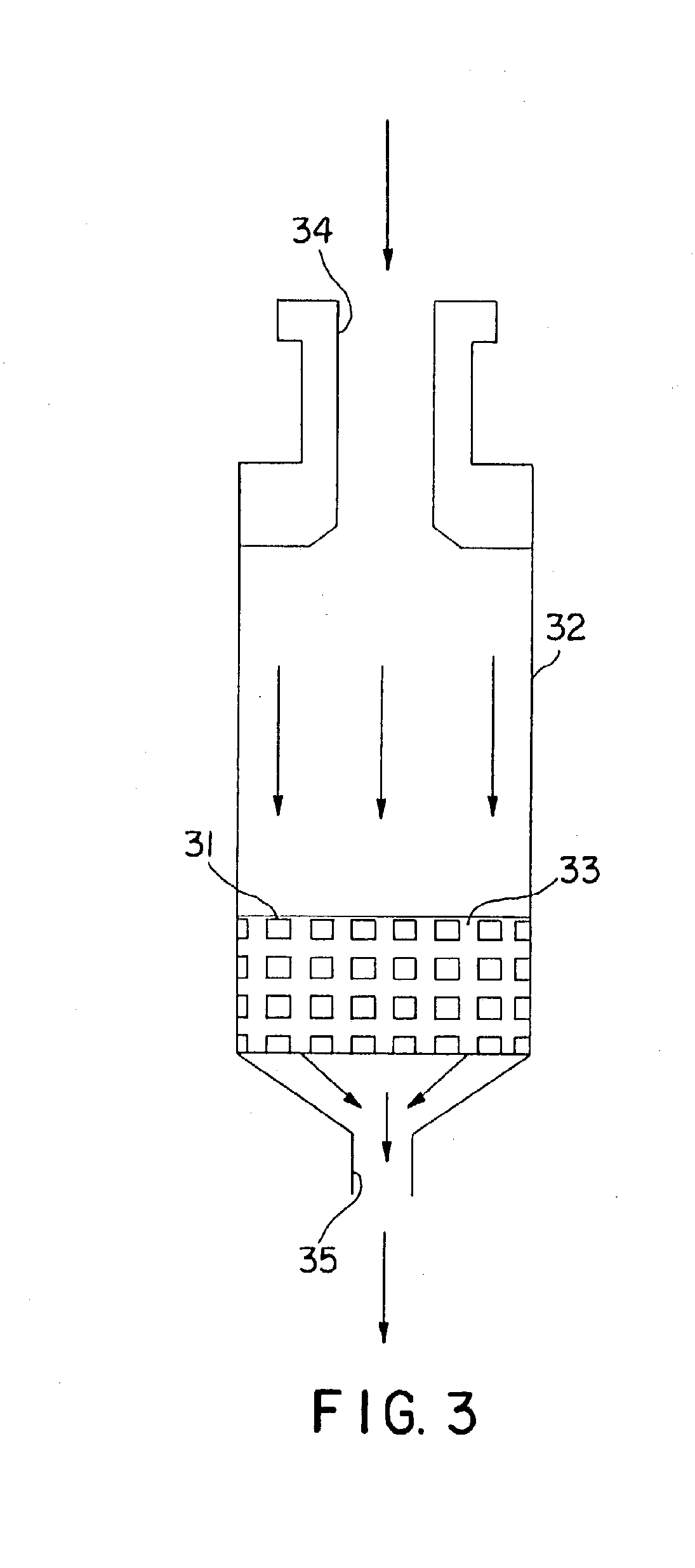

example 3

[0049] The agarose-filled cylinder in Example 2 was equilibrated in 1M NaOH for 4 hours. The NaOH was drained out and the agarose was cross-linked using 3% epichlorohydrin in 95% (VIV) ethanol / water mixture for 16 hours at room temperature. The resulting cross-linked gel can be used a filtration device. The liquid permeability of the device after cross-linking increased slightly to about 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basicity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

| Polymeric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com