Phase change material and non-volatile memory device using the same

a phase change material and non-volatile memory technology, applied in the direction of bulk negative resistance effect devices, semiconductor devices, electrical equipment, etc., can solve the problems of stability problems, slow writing speed, disadvantages of sb-te based alloys, etc., and achieve the effect of smaller diatomic bond strength and higher atomic number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

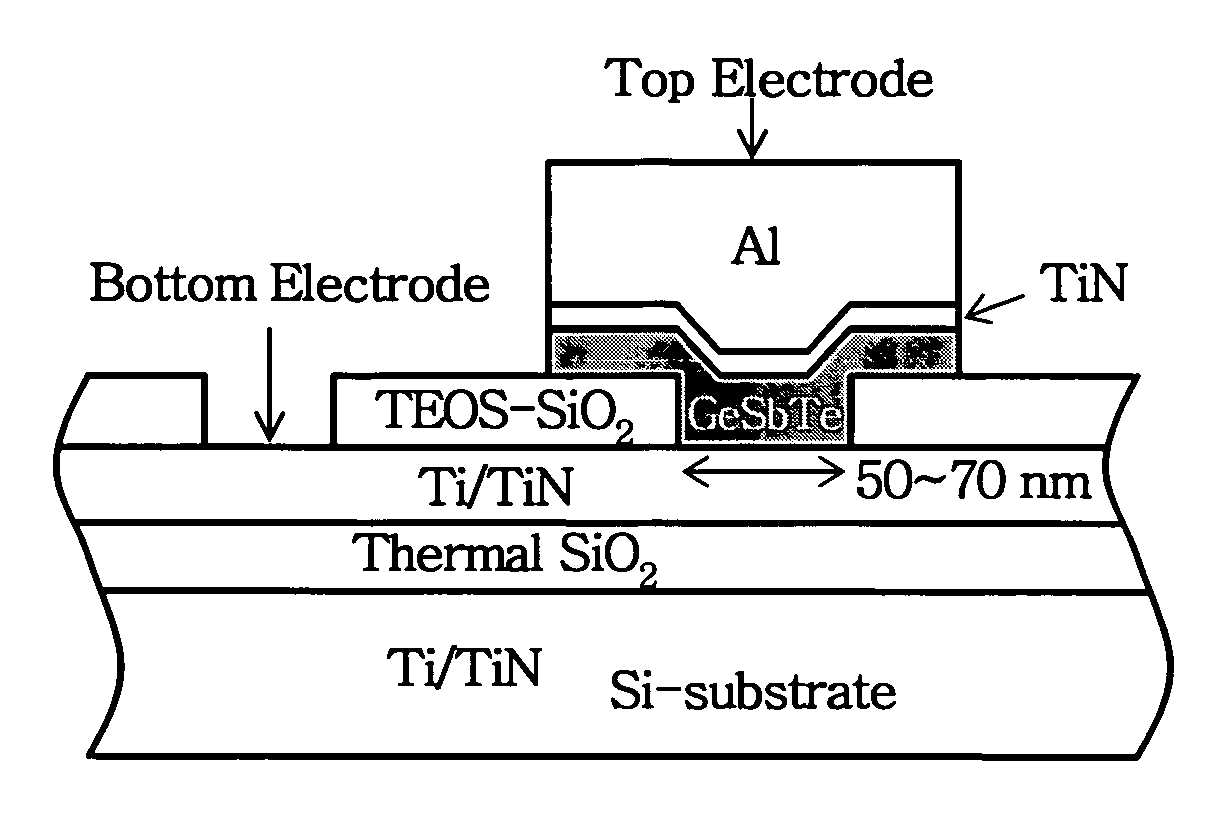

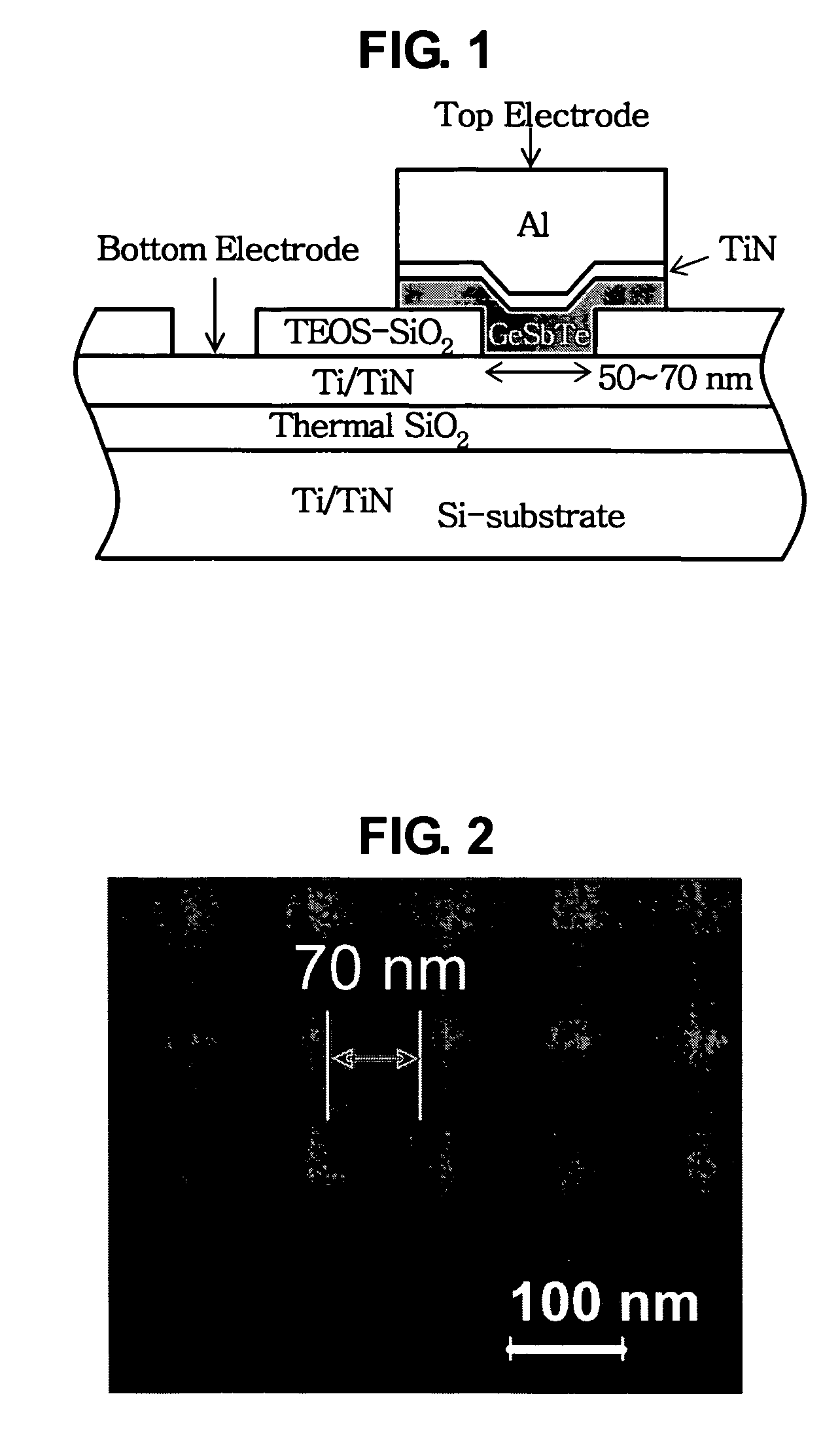

[0037] An off-set type phase change memory cell as shown in FIG. 1 was prepared according to the following procedures. 200 nm-thick SiO2 film was deposited on silicon substrate. Ti / TiN film, as a bottom electrode, was deposited thereon at a thickness of 100 nm, respectively. Next, 100 nm-thick SiO2 was formed thereon. As shown in SEM picture of FIG. 2, a contact hole of 70 nm was formed by electron beam lithography.

[0038] Next, as a phase change material, solid solution of (Ge1Sb2Te4)0.8(Sn1Bi2Te4)0.2 was deposited in the contact hole by PVD (physical vapor deposition) at a thickness of 100 nm. As top electrodes, 100 nm-thick TiN and 500 nm-thick Al films were sequentially deposited on the phase change material.

[0039]FIG. 1 describes a schematic diagram of an off-set type phase change memory cell including a material in accordance with the present invention. Transistor part for cell addressing is not shown in FIG. 1.

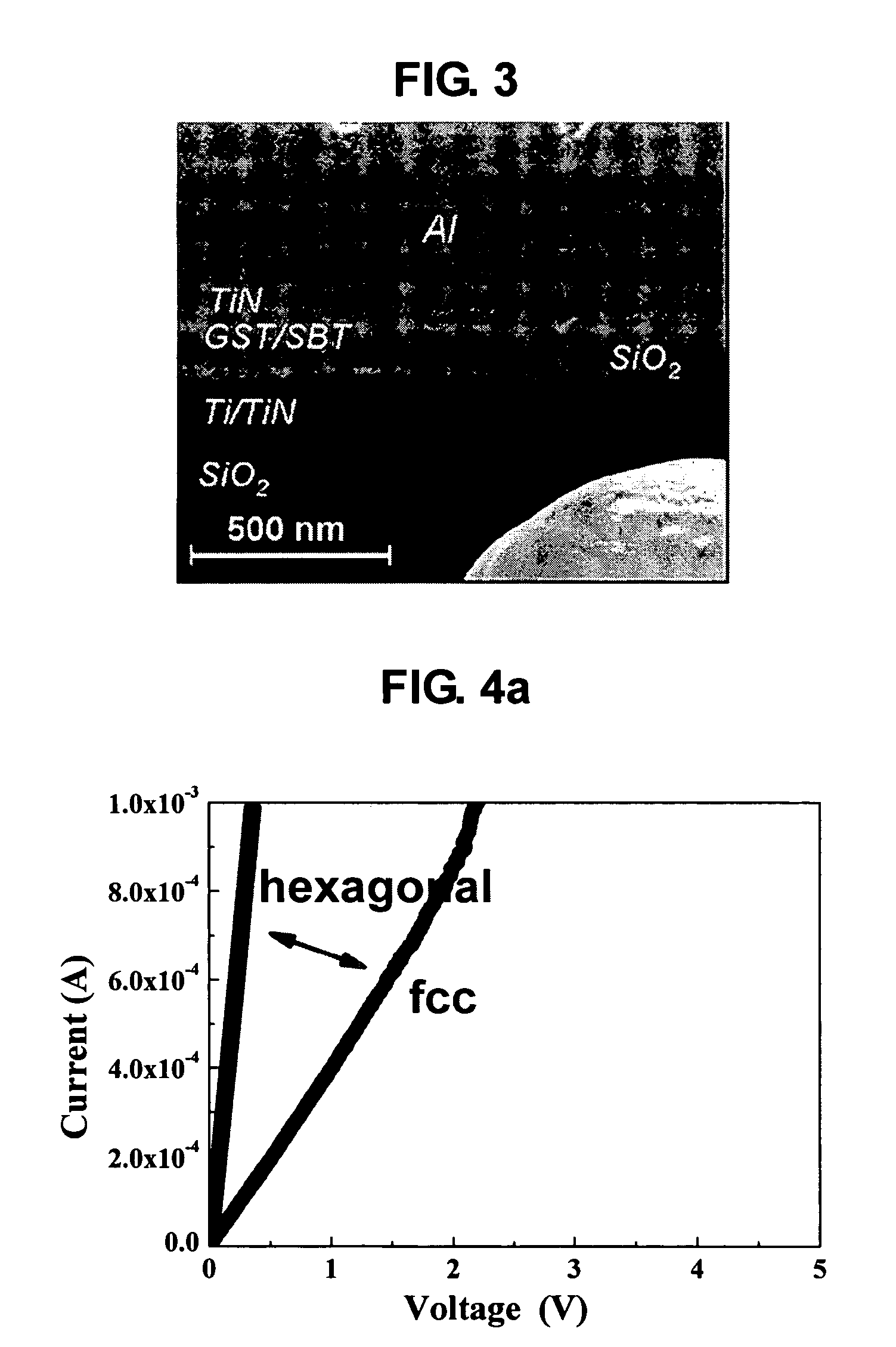

[0040]FIG. 3 illustrates sectional SEM picture of a phase change...

example 2

[0041] Procedures in Example 1 were repeated except that a solid solution of (Ge1Sb2Te4)0.9(Sn1Bi2Te4)0.1 was used instead of (Ge1Sb2Te4)0.8(Sn1Bi2Te4)0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| resistances | aaaaa | aaaaa |

| resistances | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com