Smooth outer coating for combustor components and coating method therefor

a technology of combustor components and outer coatings, which is applied in the direction of solid-state diffusion coatings, superimposed coating processes, transportation and packaging, etc., can solve the problems of reducing the service life of tbc systems, and affecting the service life of components. , to achieve the effect of reducing the component temperature and reducing the convective and radiant heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

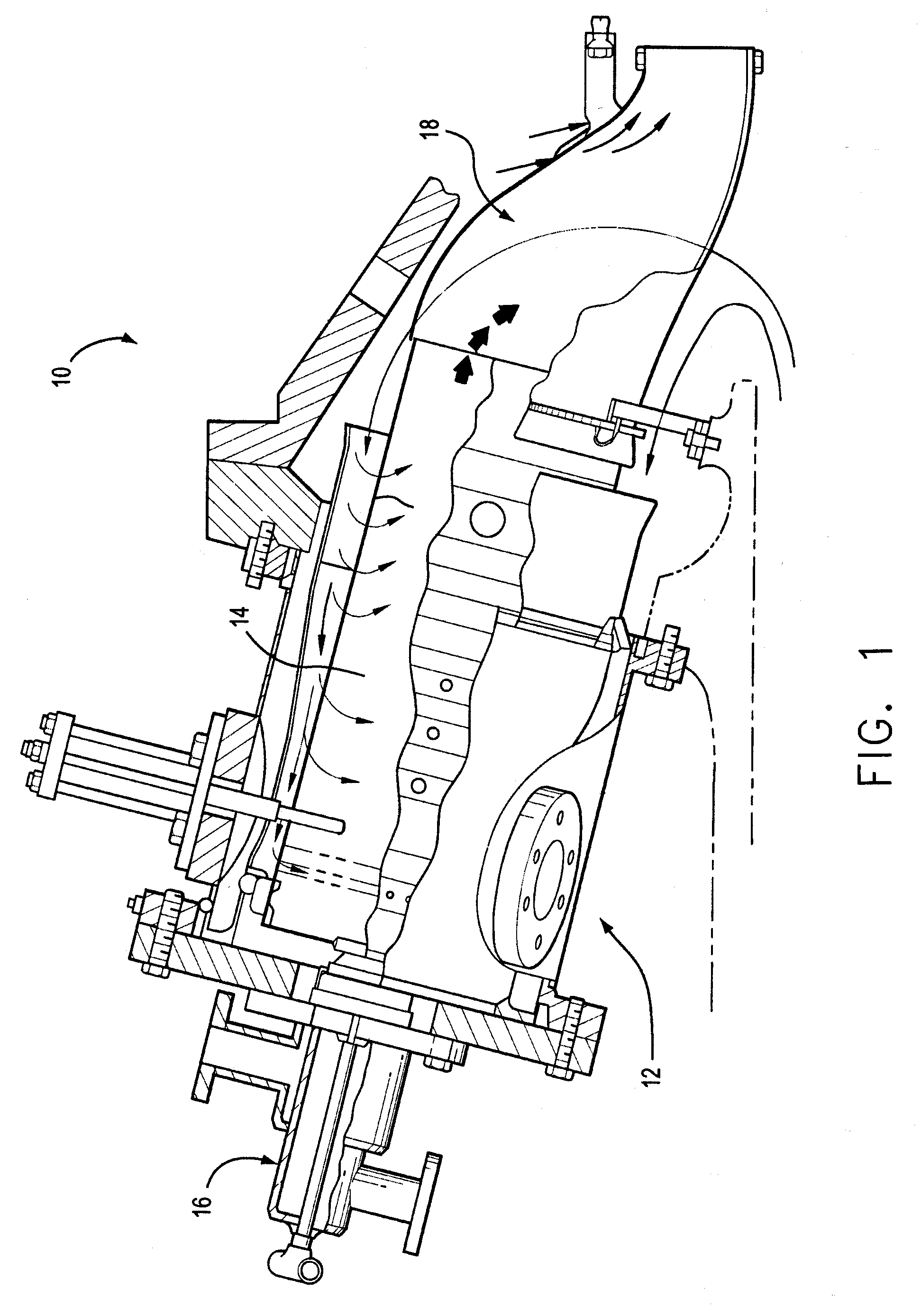

[0014] The present invention will be described in reference to a combustor 12 of an industrial gas turbine 10, a portion of which is shown in cross-section in FIG. 1. The combustor 12 is one of multiple can-annular combustors located about the periphery of the turbine 10, and has a can-type liner 14 whose interior defines a combustion chamber of the turbine 10. The liner 14 is inserted into a transition piece 18 with multiple fuel nozzle assemblies 16 located at the head end of the liner 14. Both fuel and water may be injected into the combustion chamber through the nozzle assemblies 16, with the injection of water being for the purpose of reducing combustion temperatures and consequently NOx emissions. The invention is not limited to combustors having the configuration shown in FIG. 1, but instead is applicable to other combustor configurations, such as the well-known annular type.

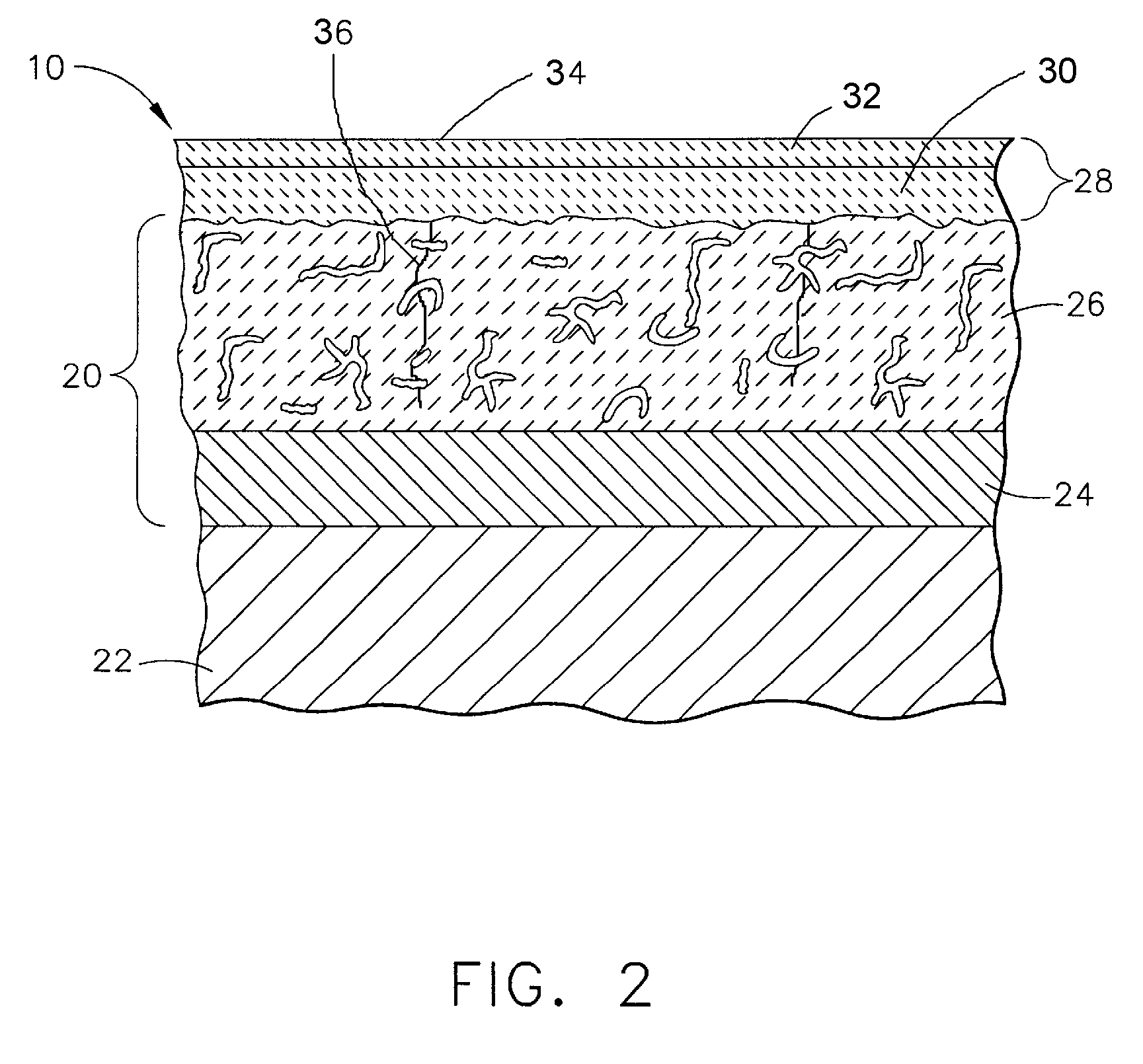

[0015] A thermal barrier coating (TBC) system 20 of a type suitable for thermally insulating the inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com