Mineral wool panel comprising a web which covers both faces thereof

a technology of mineral wool and web, which is applied in the direction of shafts, steering controls, building components, etc., can solve the problems of uneven strength and increase in strength, and achieve the effects of increasing surface strength and tensile strength, increasing structural strength of the panel, and increasing resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

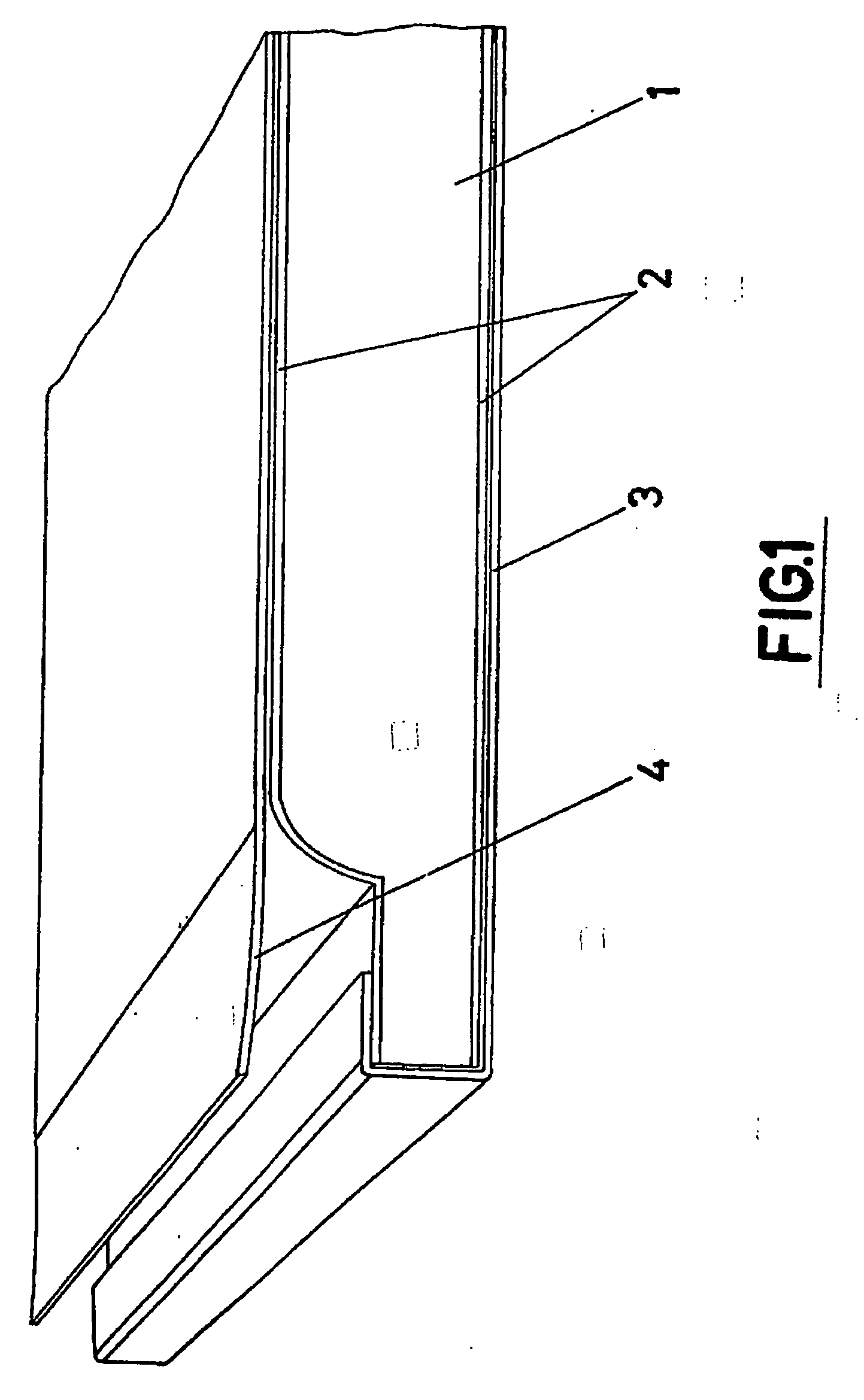

[0028] As indicated above, the detailed description of the preferred embodiment of the panel of the invention will be given below with the aid of the appended drawing. In this context, the single figure shows a schematic representation of a perspective view of the panel of the invention, which shows a mineral wool core 1, the inner and outer surfaces of which can receive, according to the invention, a web 2 on both of them, this being fastened to said surfaces, said webs extending over the totality of said respective surfaces, it being possible for the desired coatings 3, 4 to be applied to the outer face.

[0029] Each of the webs 2 incorporated on the inner and outer surfaces of the core of the panel consists of a multiplicity of glass fibers or organic polymer fibers, which are woven or nonwoven. The materials for manufacturing said webs 2 may also advantageously comprise a mixture of polymer (especially polyester) fibers and glass fibers.

[0030] By way of illustration, the grammag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com