Breath freshening confectionery products and methods of making and using same

a technology confectionery products, which is applied in the field of breath freshening confectionery products, can solve problems such as general shattering, and achieve the effect of not causing irritation in the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

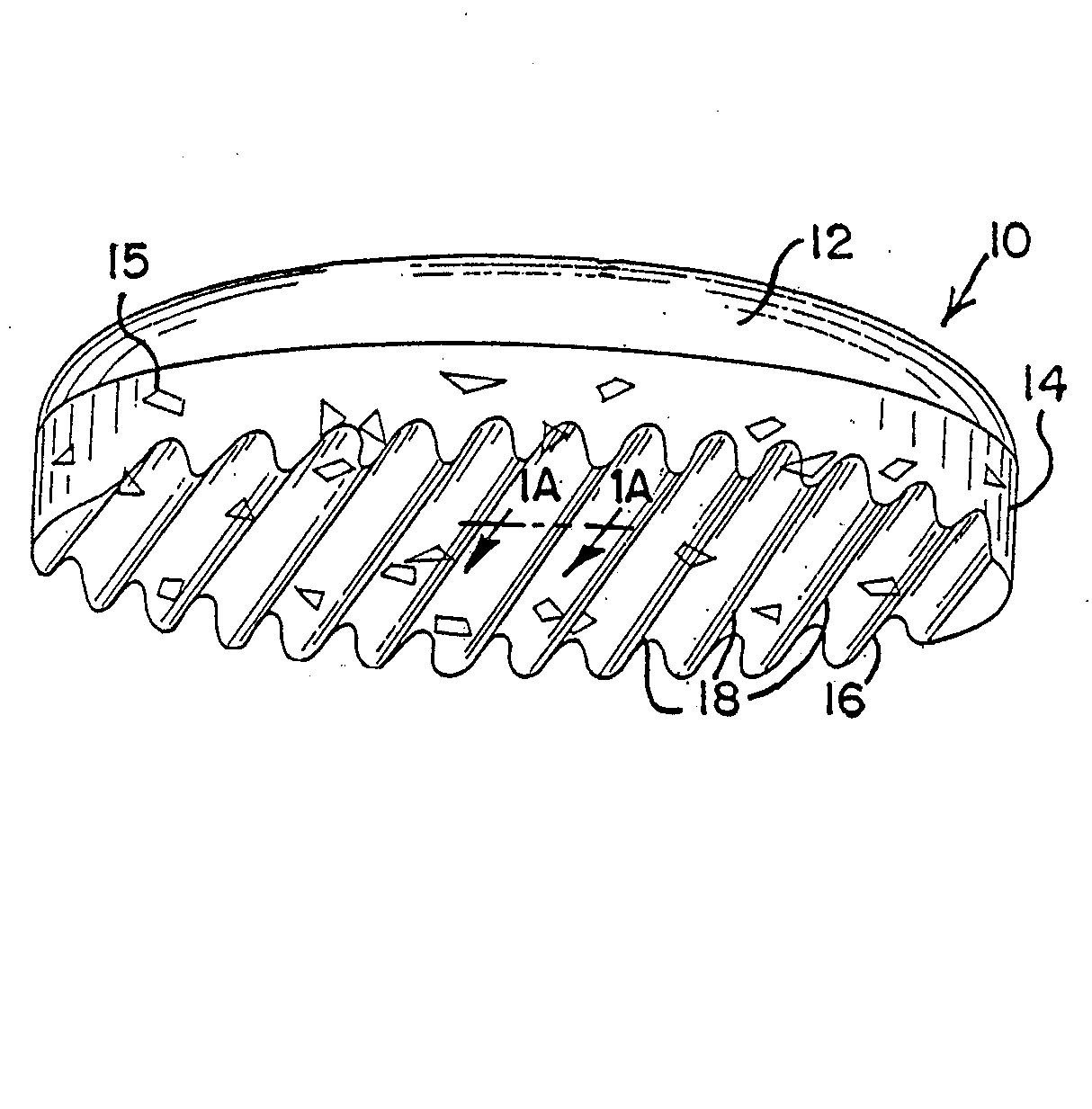

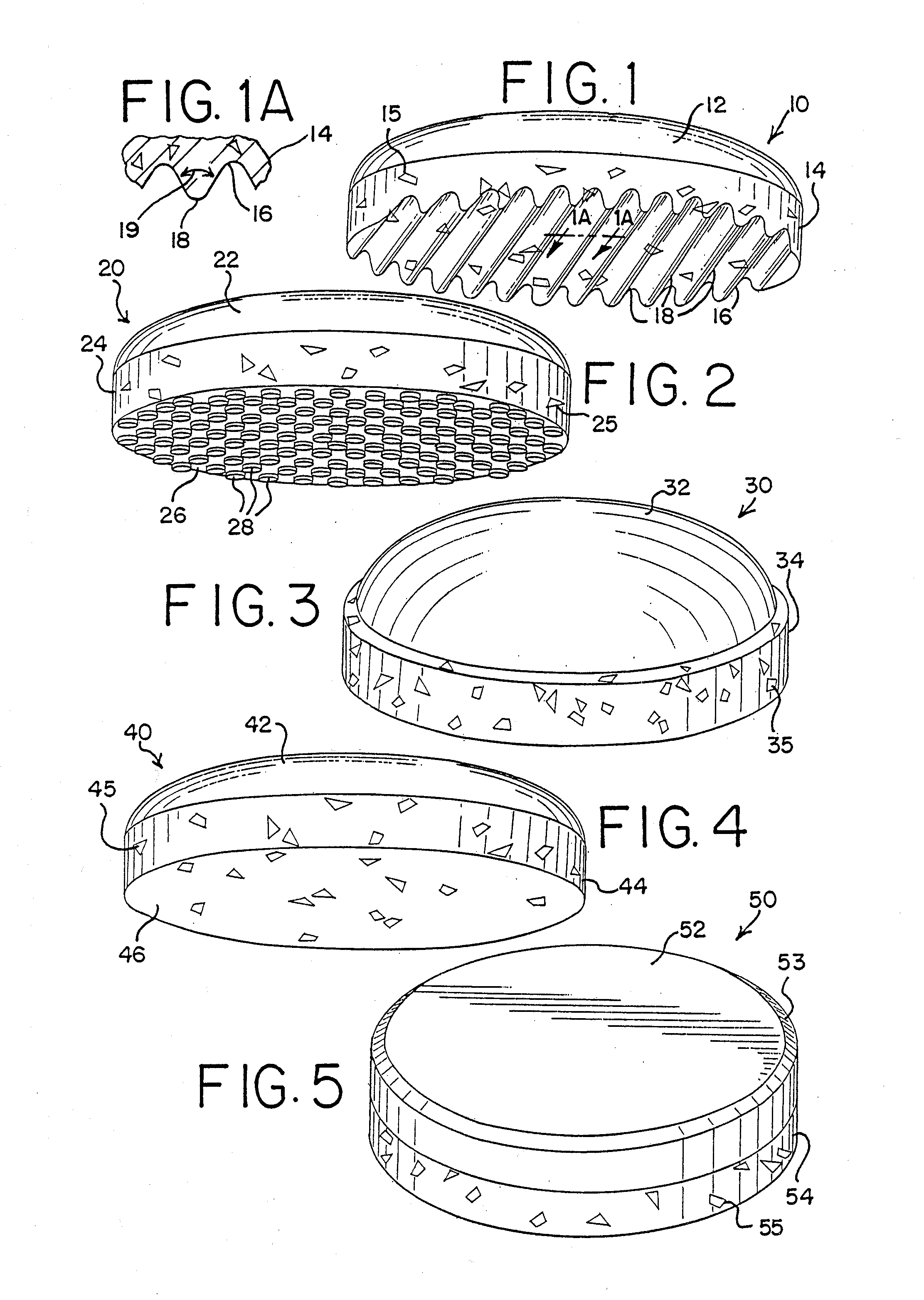

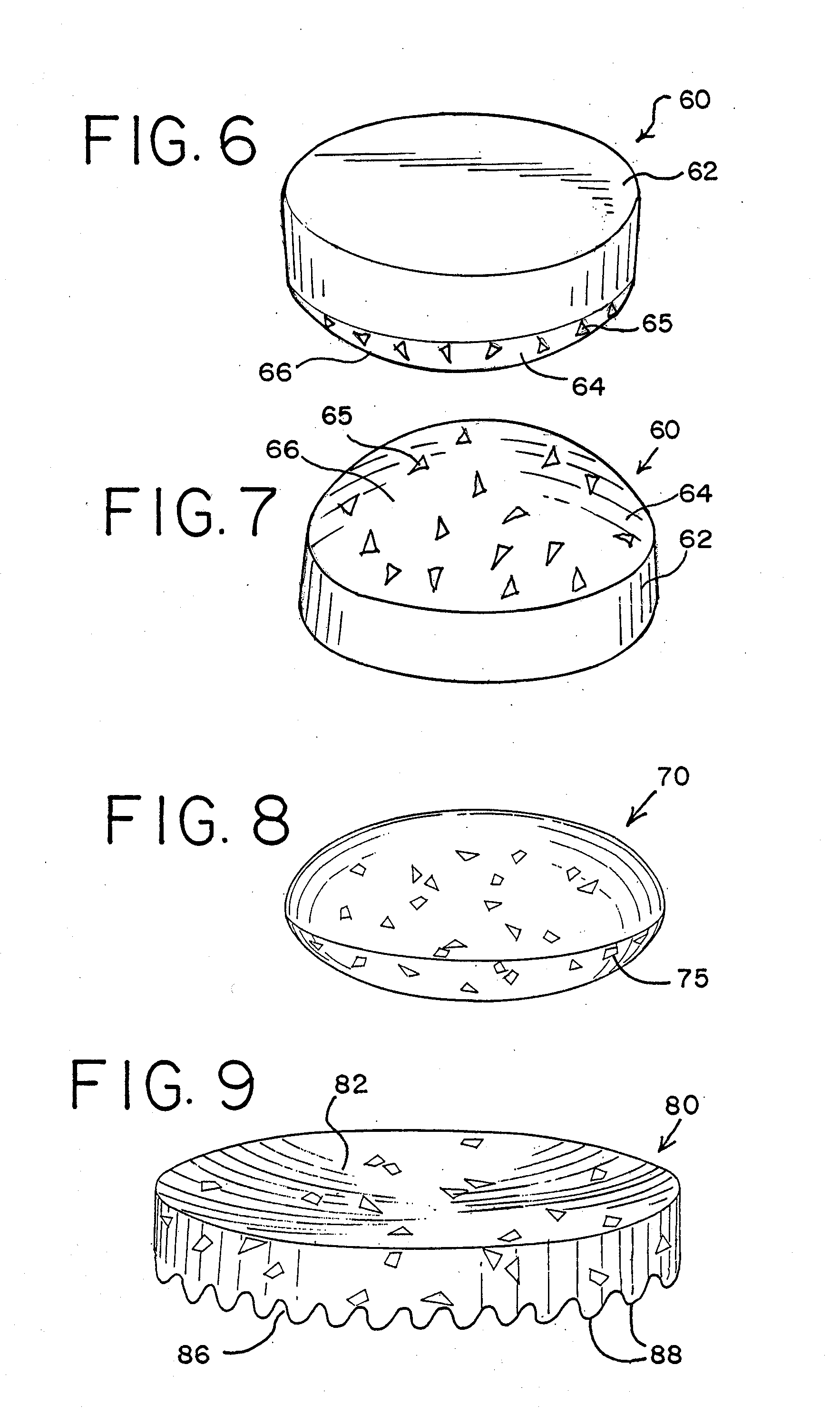

Image

Examples

example 2

Pressed Tablet

[0123]

First layer (white)Sorbitol98.11%Intense sweeteners0.34%Lemon / menthol flavor0.51%Malic acid0.06%Magnesium stearate0.98%Total100.0Second layer (blue, fizzing)Sorbitol62.36%Sodium bicarbonate19.96%Malic acid16.21%Intense sweeteners0.47%Lemon / menthol flavor0.34%Magnesium stearate0.62%Blue color0.04%Total100.0

[0124] For the first (white) layer, sorbitol, sweeteners, and acid were mixed for 5 minutes, flavor was added and mixed for 10 minutes, and then magnesium stearate was added and mixed for 2 minutes.

[0125] For the second (blue) layer, sorbitol, sweeteners, acid, bicarbonate, and color were mixed for 5 minutes, flavor was added and mixed for 10 minutes, and then magnesium stearate was added and mixed for 2 minutes.

[0126] Three parts of the white powder (about 0.66 grams) were placed in a die that included a mesh screen to form a rough surface, and tapped down. Two parts (about 0.44 grams) of blue powder were then poured into the die. The powders were compressed...

examples 3 a-h

[0129] A two layer pressed tablet was made according to the following formula.

Layer 1 (bottom, scrubbing layer)%Sorbitol (Roquette Neosorb(TM))65.94Palatinit Inclusions*32.97Magnesium Stearate0.49Peppermint Flavor0.49Aspartame0.07Acesulfame K0.02Cooling Agent (FEMA 4006)0.02100.00

*Palatinit (hydrogenated isomaltulose) particles with 0.30% food approved blue lake color sized to pass through a #20 sieve and be retained on a #40 sieve.

[0130]

Layer 2 (upper, smooth layer)%Sorbitol (Roquette Neosorb(TM))98.91Magnesium Stearate0.49Peppermint Flavor0.49Aspartame0.07Acesulfame K0.02Cooling Agent (FEMA 4006)0.02100.00

[0131] Ingredients in the above formulas were dry blended together. A quantity of Layer 1 powder equal to 40% of the total piece weight was loaded into the die with lower punch (with tongue-cleaning features) inserted and compressed lightly by hand with the upper punch. The upper punch was removed and cleaned of loose powder. A quantity of Layer 2 powder equal to 60% of the to...

example 4

[0134] The Example 3 Layer 1 and Layer 2 formulas were tableted as in Example 3 but on a Stokes BB2 3-layer, 24 station tablet press with dies and punches shaped to make the tablet shown in FIGS. 39 / 40, having a tablet weight of approximately 1.1 g, a width of 0.465 inches and a length of 0.625 inches. An initial compression pressure was set and a few tablets were made. These were tested for hardness and the compression pressure adjusted up or down to produce tablets of the desired hardness, a target of 30 Kp. The force used to produce that hardness was 3.65 US tons, or 7300 pounds. This setting was dependent on the size and shape of the tablet produced. For the tablet of FIGS. 39 / 40, with a thickness of approximately 8.9 mm, a width of 0.465 inches and a length of 0.625 inches, the tablet has a maximum cross-sectional area of about 0.228 square inches. Thus, the 7300 pounds of force produced a pressure of about 32,000 psi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com