Fixed cutter drill bit for abrasive applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

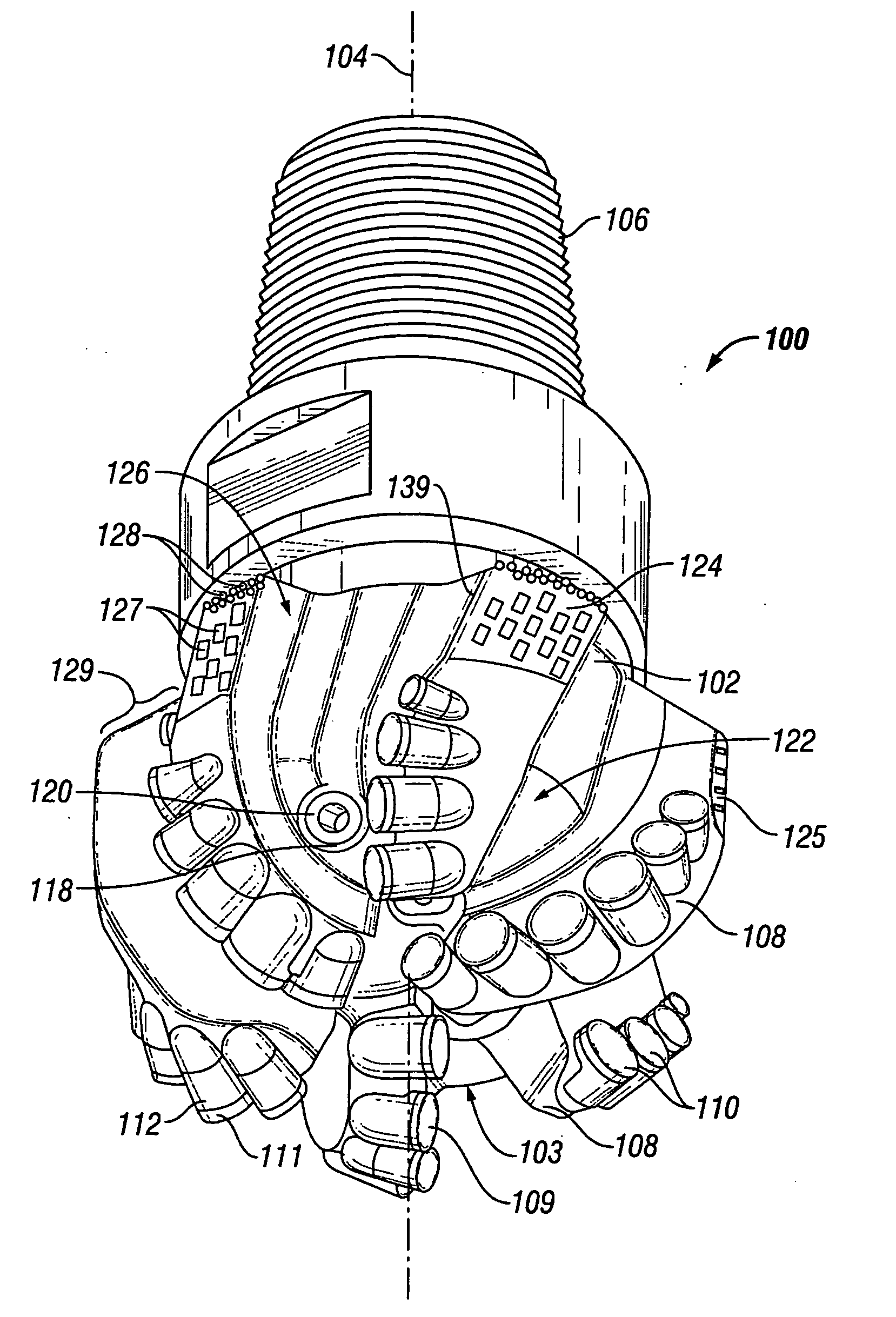

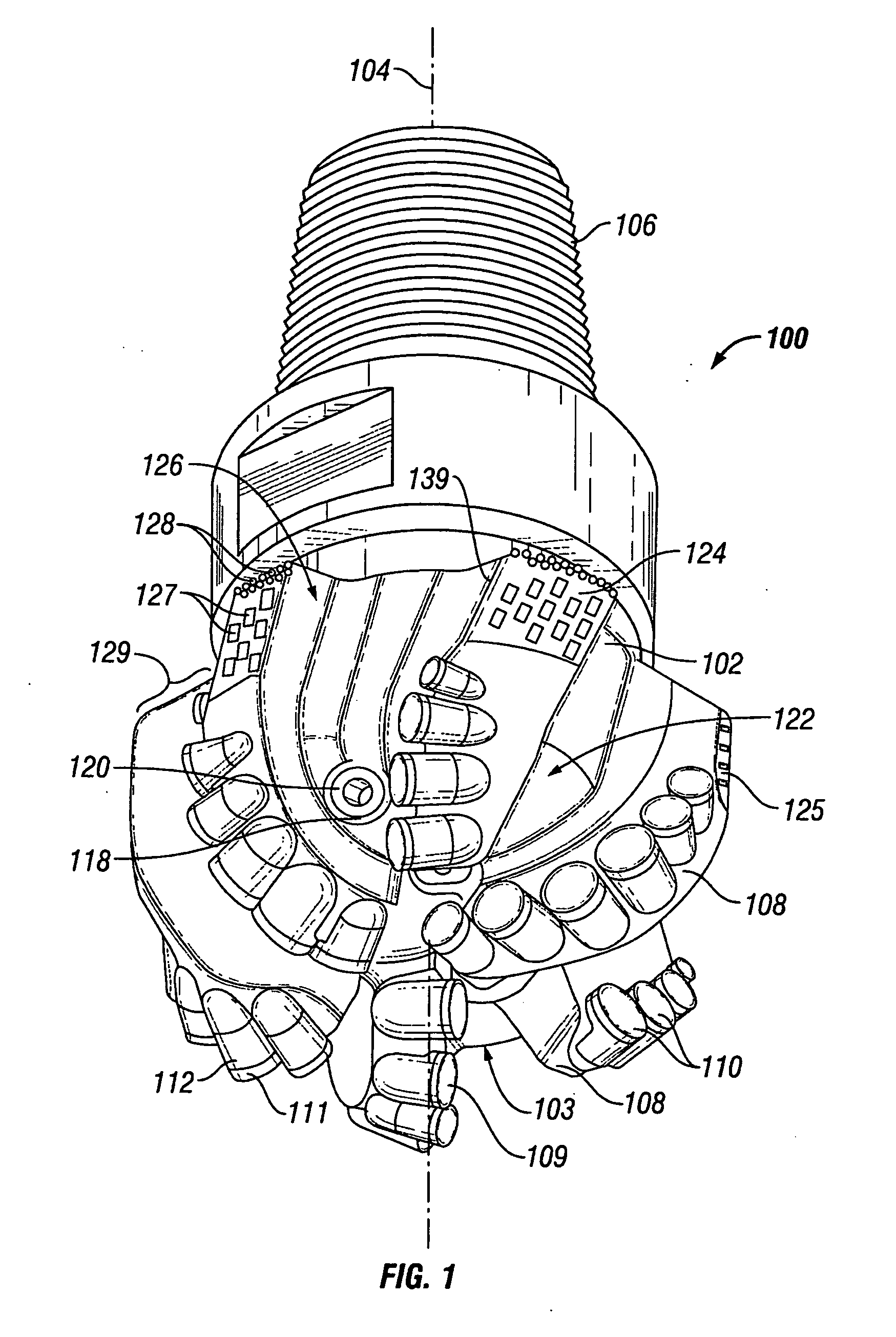

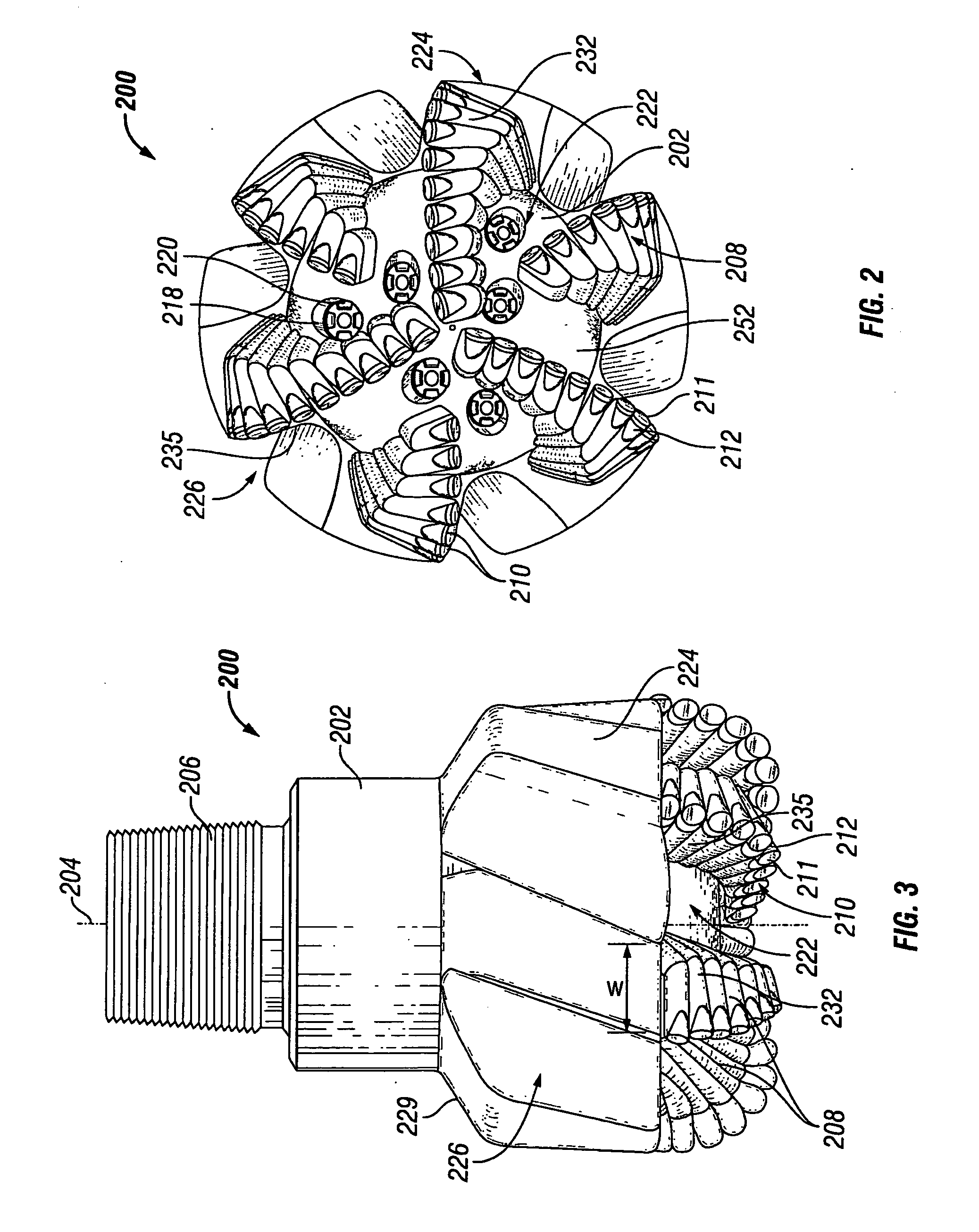

[0031]Reference will now be made to the figures in which various embodiments of the present invention will be given numerical designations and in which aspects of the invention will be discussed so as to enable one skilled in the art to make and use embodiments of the invention.

[0032]In one aspect, the present invention provides a fixed cutter drill bit for drilling earth formations, which may be particularly useful in drilling formations comprising unconsolidated to low compressive strength, yet highly abrasive sands, such as those encountered in heavy oil reservoirs. These types of formations will be generally referred to as “unconsolidated and ultra abrasive” for simplicity. In another aspect, the present invention provides novel gage pad configurations for drill bits, which may be particularly useful on bits designed for any abrasive drilling environment. In another aspect, the invention provides methods for manufacturing or rebuilding fixed cutter bits.

Conventional PDC Bits

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com