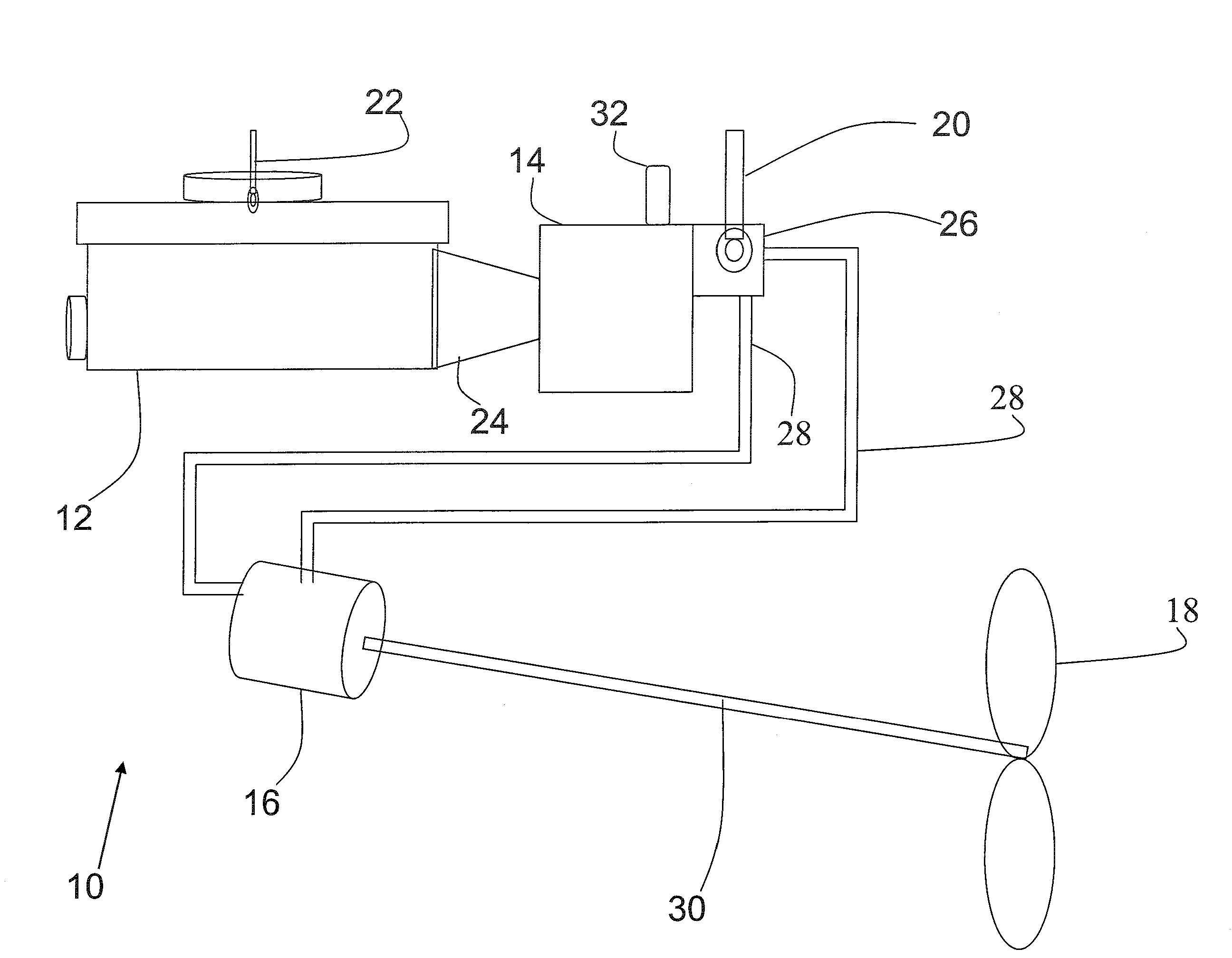

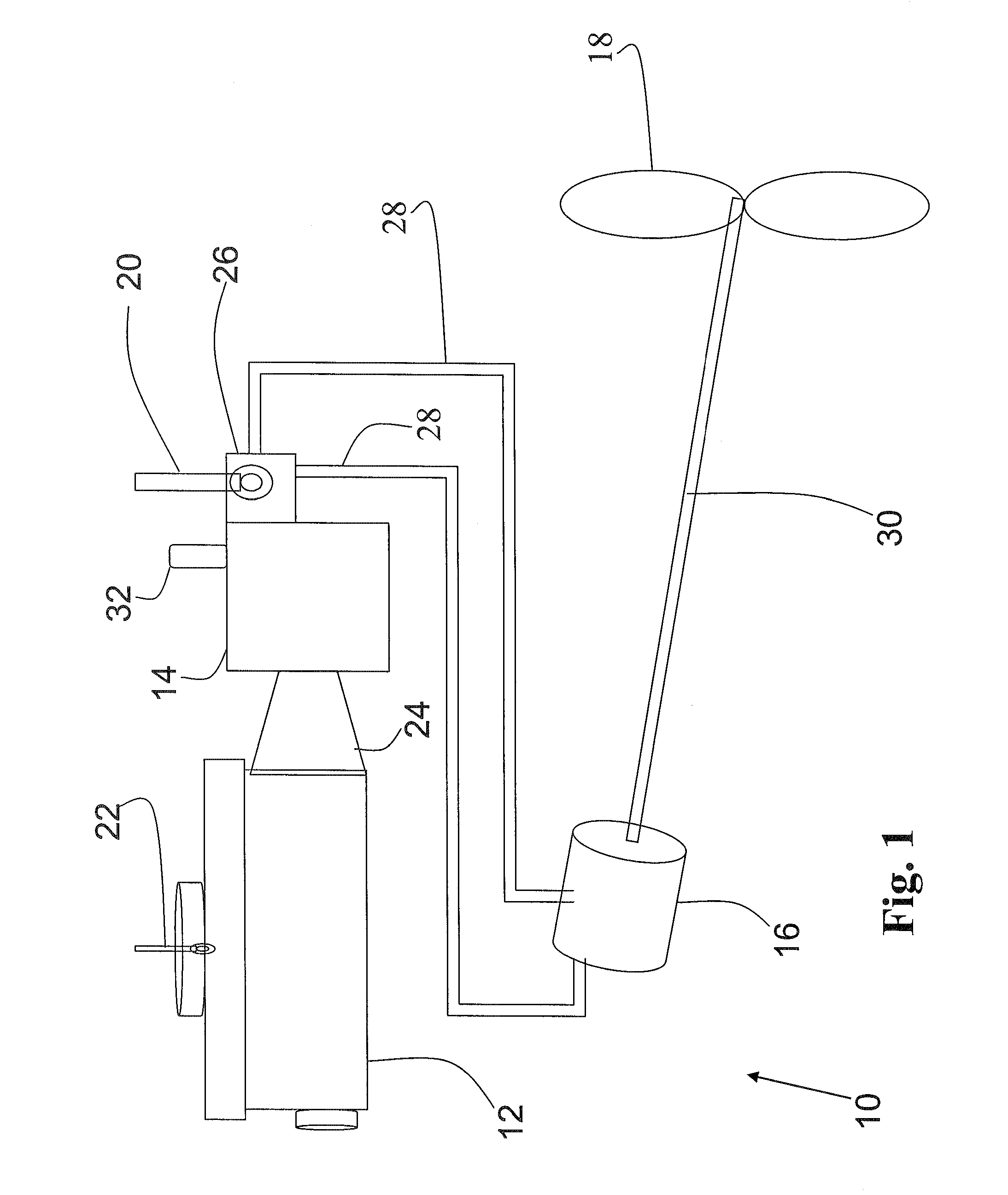

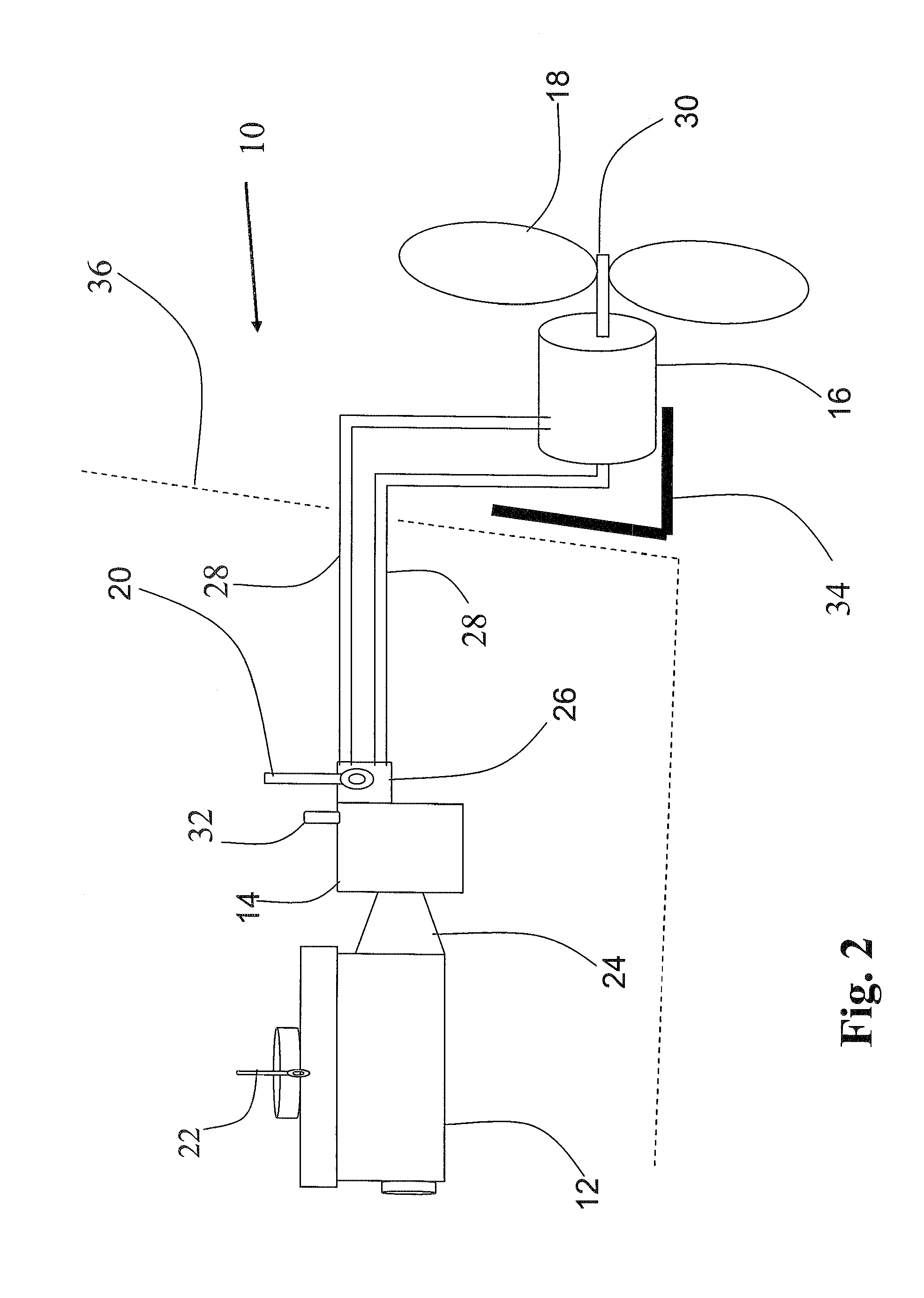

Hydra-marine propulsion system

a propulsion system and hydro-marine technology, applied in the direction of motor-driven power plants, vessel construction, transmissions with non-mechanical gearings, etc., can solve the problems of increasing reliability, reducing maintenance costs, and environmental impact, so as to reduce the weight of the drive system, reduce the impact of environmental impact, and reduce the fuel requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0036]A 220 hp (horsepower) diesel engine at 1500 rpm will develop 650 ft -lbs (foot-pounds) of torque with a fuel burn rate of about 3.4 gallons (12.87 liters) per hour under load. Note: Driven by the engine at this rate, the hydraulic pump reduces (max flow) from 0 to 7,500 psi (pounds / inch2). Note 1 psi equals 0.07103 kilogram.force per square centimeters (kgf / cm2). With the propeller attached directly to a variable displacement torque drive, shaft speeds from 1 rpm to 5,000 rpm can be achieved through the 12 v DC hand operated flow control, mounted at the helm.

[0037]Hull speeds will vary depending on the type, length, width, weight, draft, wetted surface area and prop configuration.

[0038]In direct comparison, a conventional system will burn about 12-20 gallons (45.42-75.71 liters) of fuel per hour at full throttle. This system will burn 3.4 gallons (12.87 liters) per hour or less to achieve the same performance.

System Advantages

[0039]In addition to the lower fuel consumption rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com