Water treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

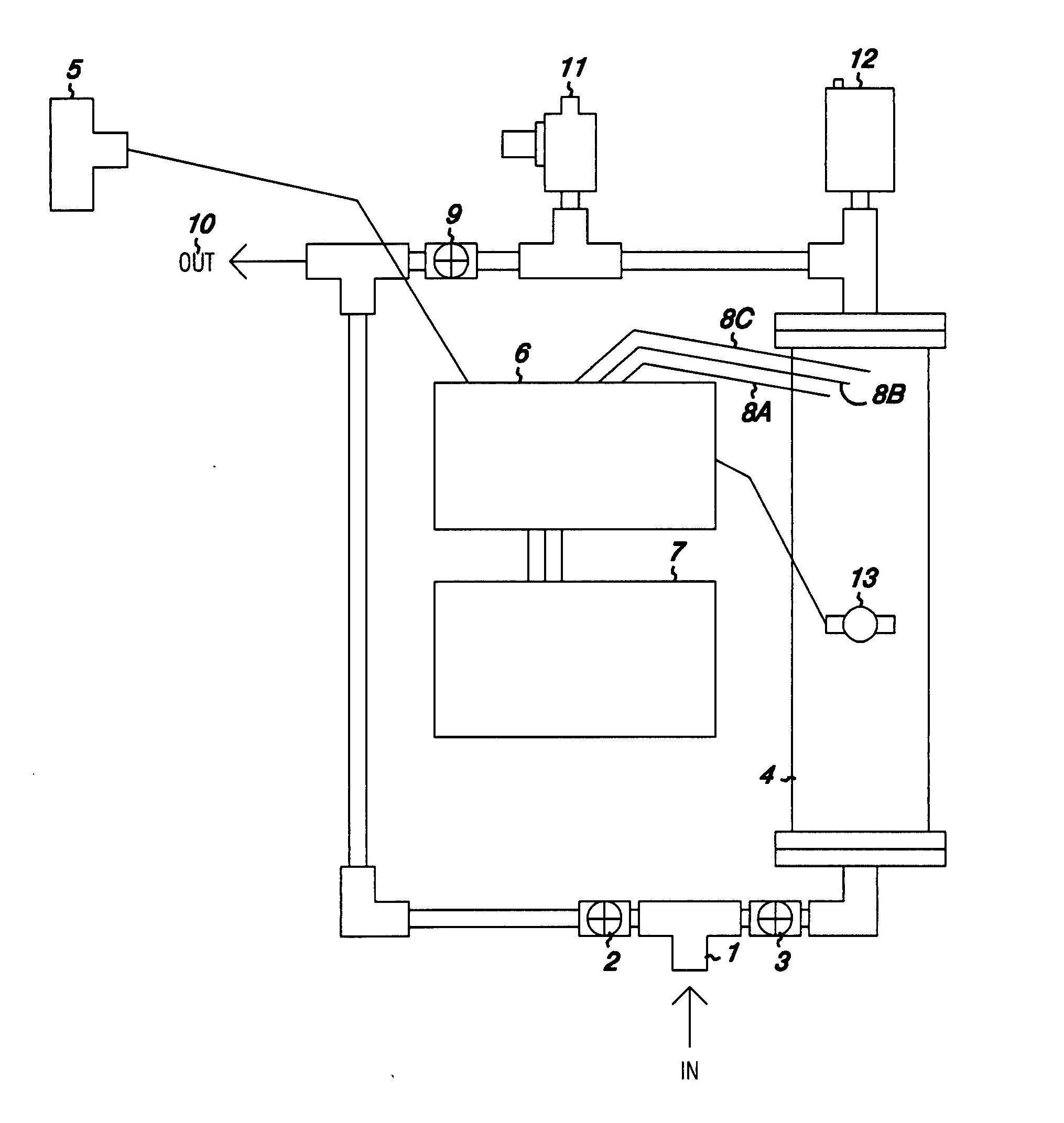

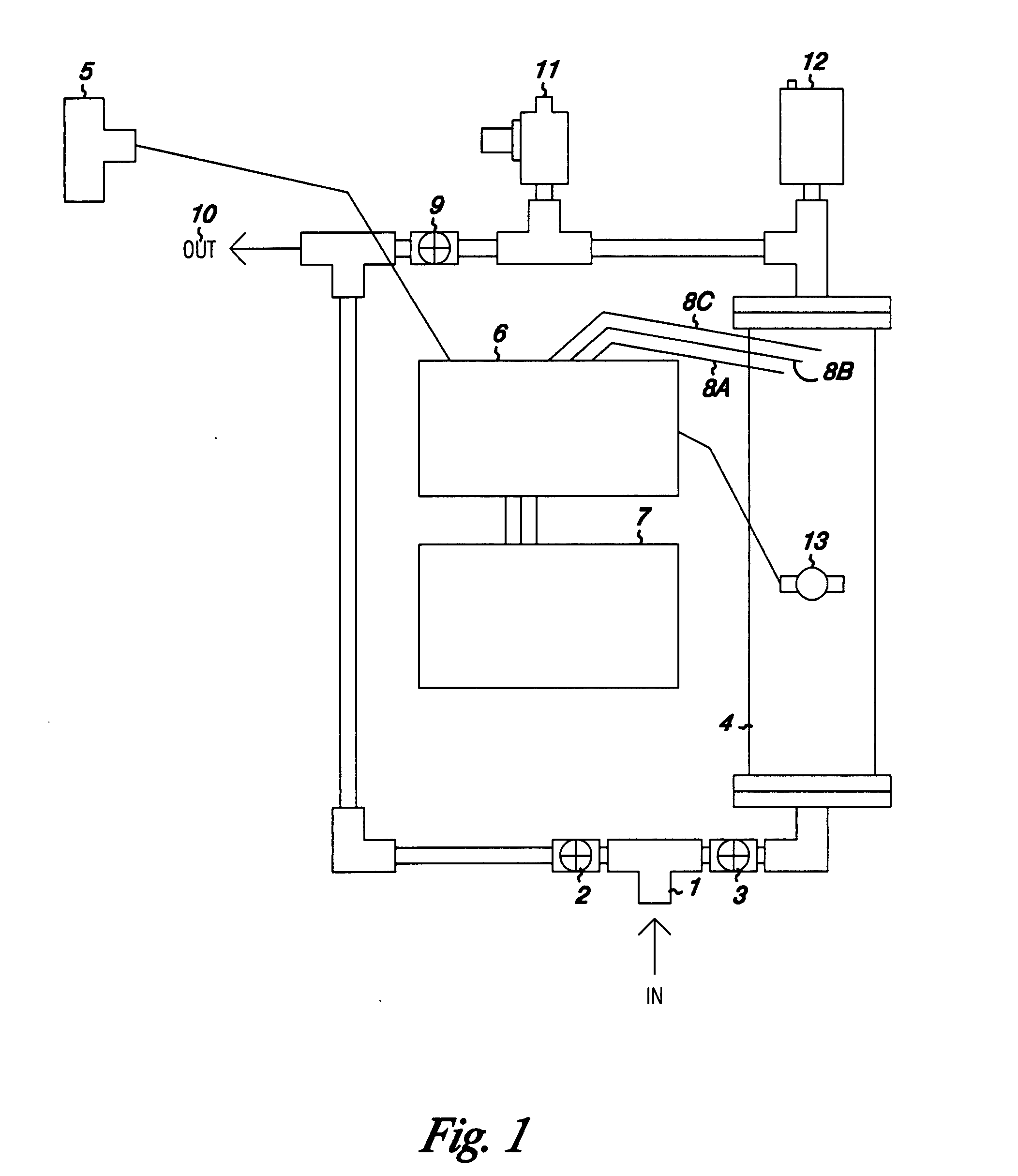

[0026]Turning to FIG. 1, the intake 1 is attached to the water supply to be treated. Valve 2 is shut; valve 3 is open to allow water into the electrolysis chamber 4. When the flow switch 5 connected to the controller 6 senses the water flow, the power supply 7 supplies voltage to the plates 8a, 8b and 8c, causing oxygen to be evolved. The oxygenated water passes valve 9 to exit by the outlet 10. Water pressure relief valve 11 and gas relief valve 12 will relieve pressure in the system. When the temperature sensor 13 senses an increase in temperature, the controller 6 inactivates the plates 8a, 8b and 8c.

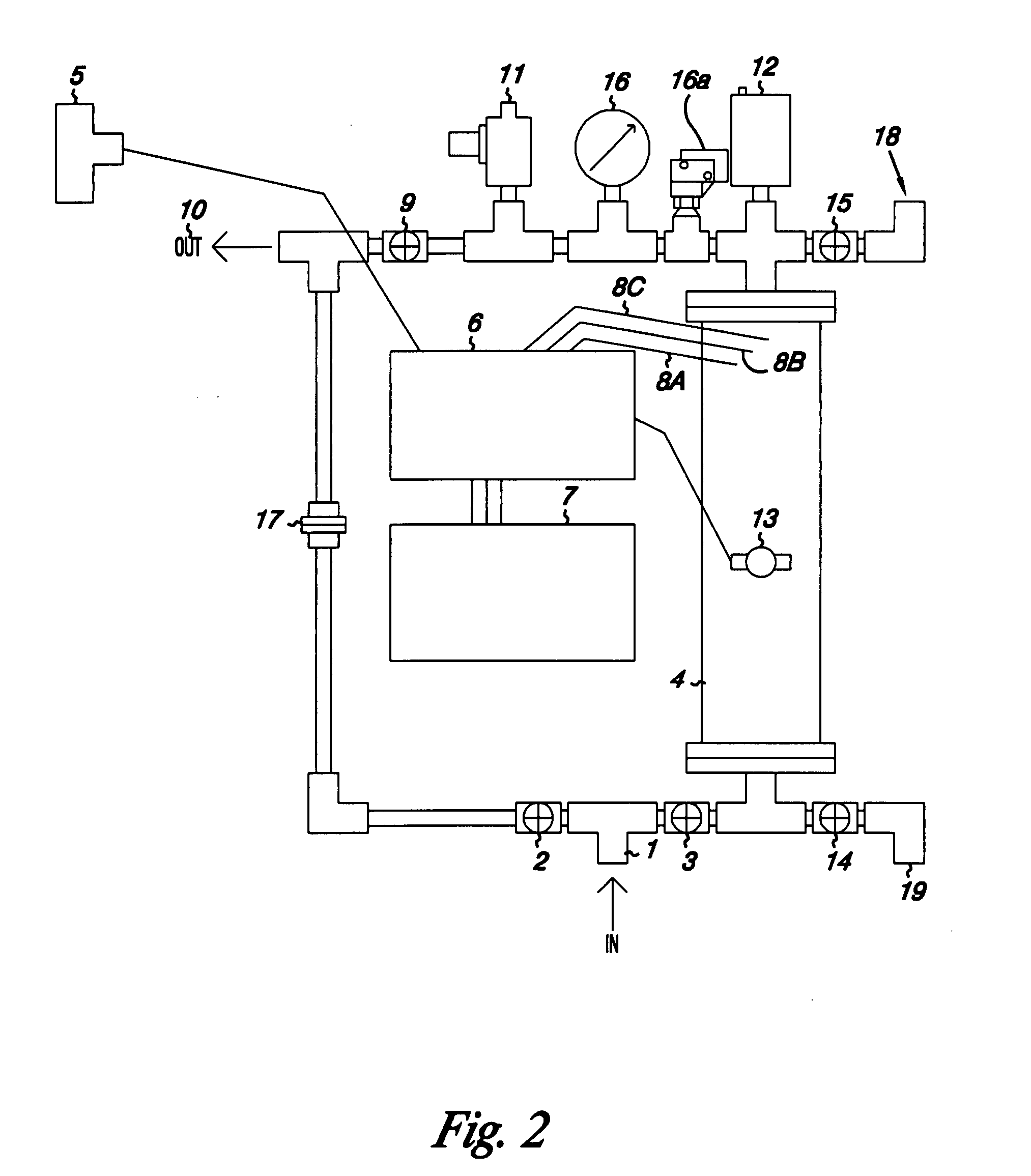

[0027]Turning to FIG. 2 the intake 1 is attached to the water supply to be treated. Valve 2 is shut; valve 3 is open to allow water into the electrolysis chamber 4. Valves 14 and 15 are closed. When the flow switch 5 connected to the controller 6 senses the water flow, the power supply 7 applies voltage to the plates 8a, 8b and 8c, causing oxygen to be evolved. The...

example 2

Description of Circuit Operation

[0033]This description is based on a example system with three emitters and the self cleaning polarity reversal on each initiation of water flow. Adjustments can be made for bigger or smaller systems. Circuit operation starts with applying line voltage, 120 V AC, to the power supply 26, which transforms the line voltage to 12 V DC. The controller circuit is in electrical communication with flow switch 23, temperature sensor 22 and push button switch 21 which activates the circuit, if the temperature sensor 22 indicates cool, thereby allowing 12 volts to be applied to the push button switch 21. When this push button switch is pushed, it energizes relay 24 K1A. The connections on this relay are such that it remains energized after the push button is released. The other contacts on this relay look at the flow switch to see if water is flowing. If so, the next relay 25 K1B is energized, applying 120 V AC to the second power supply 20 and relay 27 K2. K2 i...

example 3

Emitter Configurations

[0036]Depending on the volume of fluid to be oxygenated, the emitter of this invention may be shaped as a circle, rectangle, cone or other model. One or more may be set in a substrate that may be metal, glass, plastic or other material. The substrate is not critical as long as the current is isolated to the electrodes by the nonconductor spacer material of a thickness from 0.005 to 0.140 inches, preferably 0.030 to 0.075 inches, most preferably 0.065 inches. Within this distance, micro- and nanobubbles of oxygen are evolved. These bubbles are so small that they cannot escape and build up into what may be termed a colloidal suspension of oxygen in an aqueous medium. Oxygen concentrations of 260% of calculated saturation at a particular temperature and pressure have been achieved in a stationary container. The oxygen suspension in a flow-through unit can be so concentrated with oxygen that the water appears milky. In addition to the high oxygen content achieved, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com