Biomass treatment of organic waste materials in fuel production processes to increase energy efficiency

a technology of organic waste and fuel production process, applied in the field of material conversion, can solve the problems of reducing the net positive energy gain (input versus output) substantially, further processing and refinement of residuals are energy intensive, etc., and achieve the effect of improving the overall energy efficiency of the fuel making process and making the overall process more energy efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

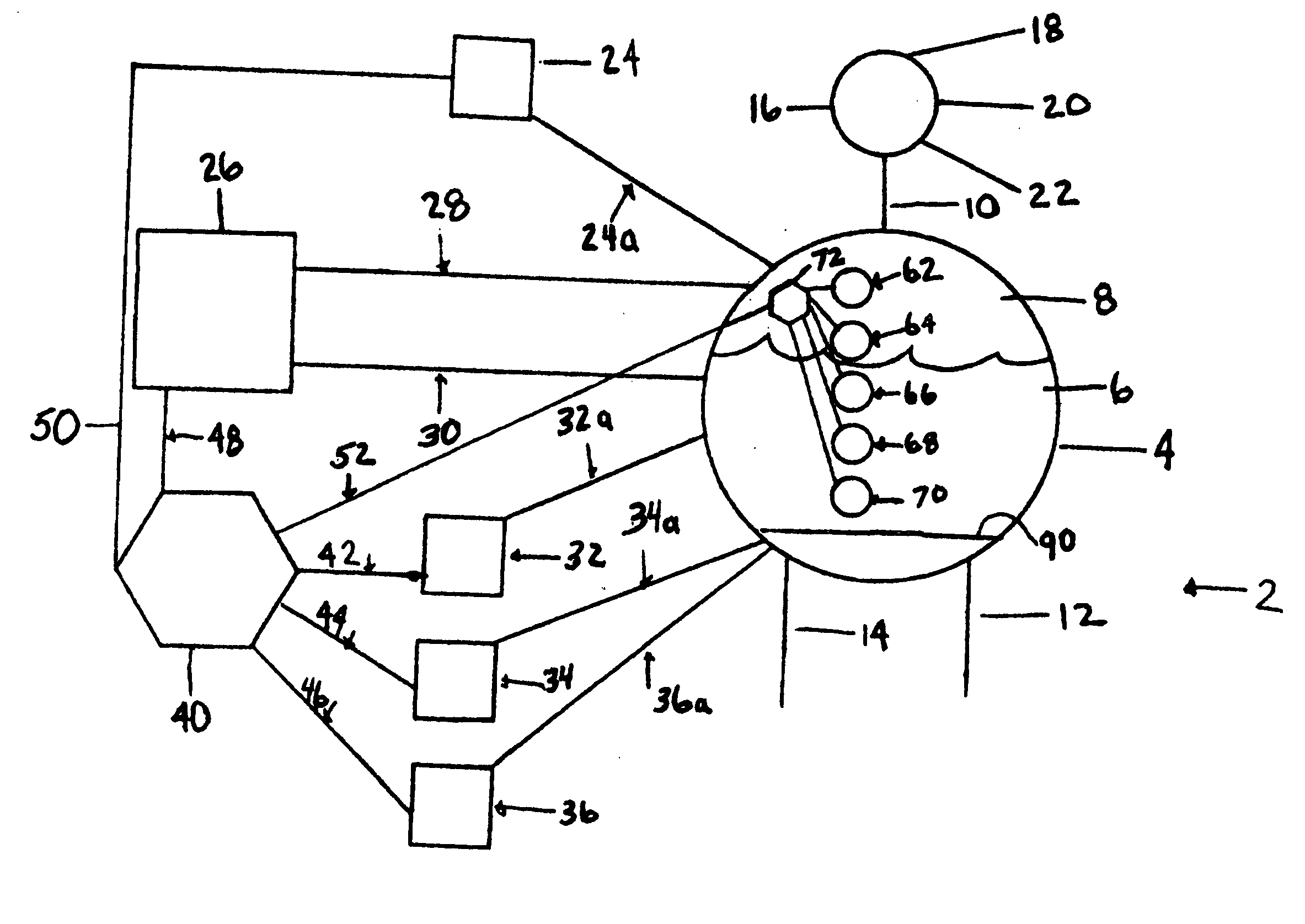

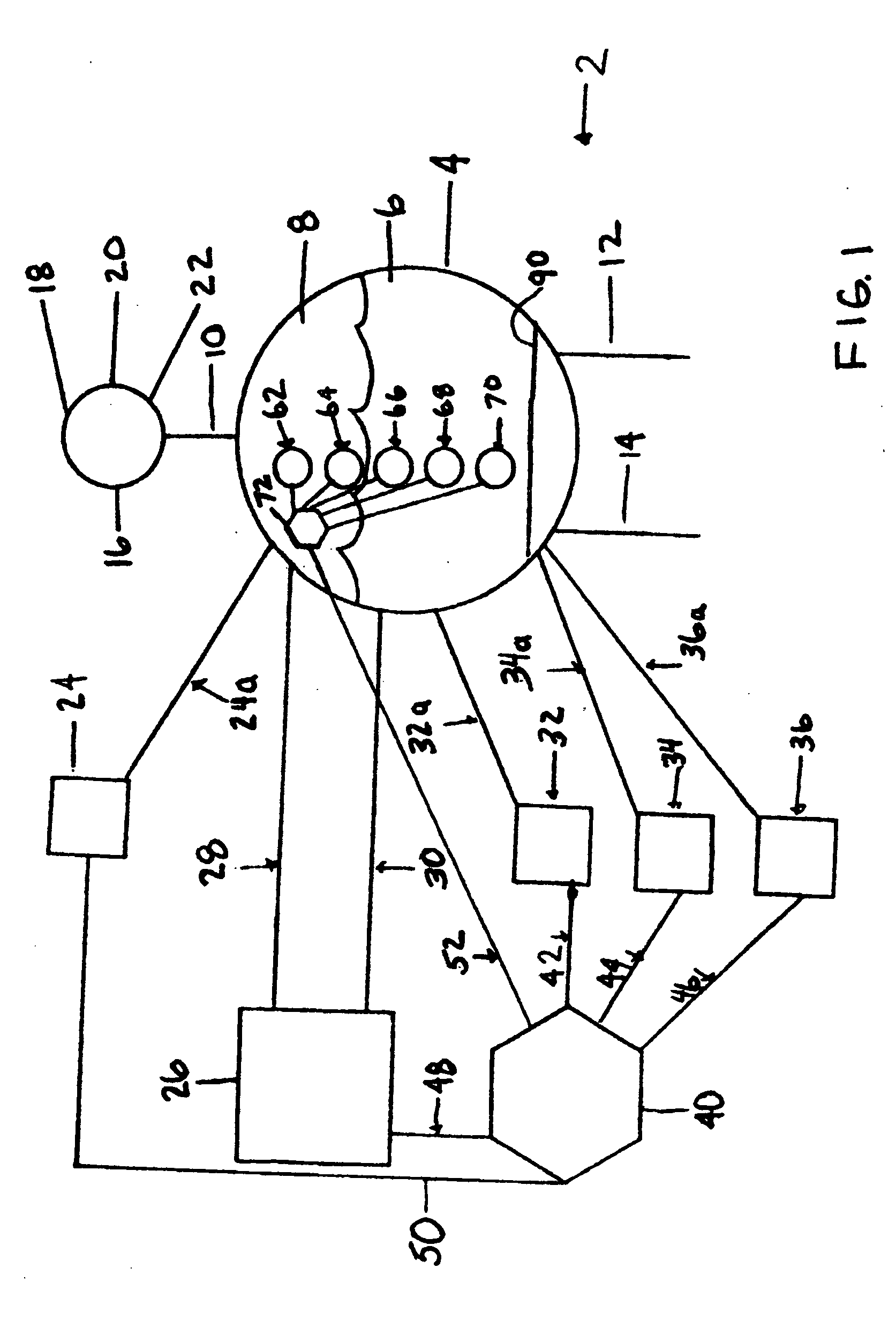

Image

Examples

Embodiment Construction

[0026] The present technology covers a wide range of potential commercial practices, and even where a specific field-of-use is described as an example, or specific equipment, or specific chemistry, or specific bacteria, or specific conditions are described, these specific teachings are to be interpreted as species examples within the scope of the generic concepts disclosed herein. For example, one specific field of use method that is contemplated within the generic scope of the technologies originally disclosed herein is a method of bioconversion of organic waste material from a synthetic fuel manufacturing process. The synthetic fuel manufacturing process requires energy input in the performance of the synthetic fuel manufacturing process. The method itself comprises: providing a tank for bioconversion of organic waste material, at least some of which organic waste material is derived from a synthetic fuel manufacturing process and the tank containing an active biomass comprising a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com