Lubricating oil compositions

a technology of lubricating oil and composition, applied in the direction of lubricant composition, liquid carbonaceous fuel, fuel, etc., can solve the problems of network formation, deficiency in one or more of the others, and poor thickening efficiency of amorphous ocp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

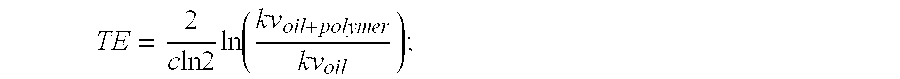

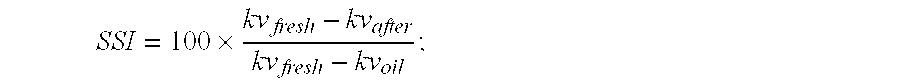

[0099]Various polymeric VI improvers and VI improver blends were tested, in the form of a 1 wt. % polymer solution in diluent oil, to determine shear stability index, or SSI (30 cycle; ASTM D6278-98); and thickening efficiency, or TE.

VII-1 is a commercially available star polymer having a number average molecular weight (Mn) of 360,000 and comprising at least 5 arms; each of which is hydrogenated isoprene.

VII-2 is a commercially available star polymer having a number average molecular weight (Mn) of 460,000 and comprising at least 5 arms; each of which is a styrene-hydrogenated isoprene copolymer having a styrene content of about 4 mass %.

VII-3 is a commercially available, Ziegler-Natta catalyzed amorphous OCP having an ethylene-derived content of 46.2 mass % and a number average molecular weight (Mn) of 67,700.

VII-4 is a commercially available, metallocene catalyzed amorphous OCP having an ethylene-derived content of 43.8 mass % and a number average molecular weight (Mn) of 44,800....

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass % | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com