Solubilization and disposal of radioactive scale and sludge

a radioactive scale and sludge technology, applied in nuclear engineering, combustion types, lighting and heating apparatuses, etc., can solve the problems of sludge buildup in storage tanks, high pressure on formations, equipment malfunction,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

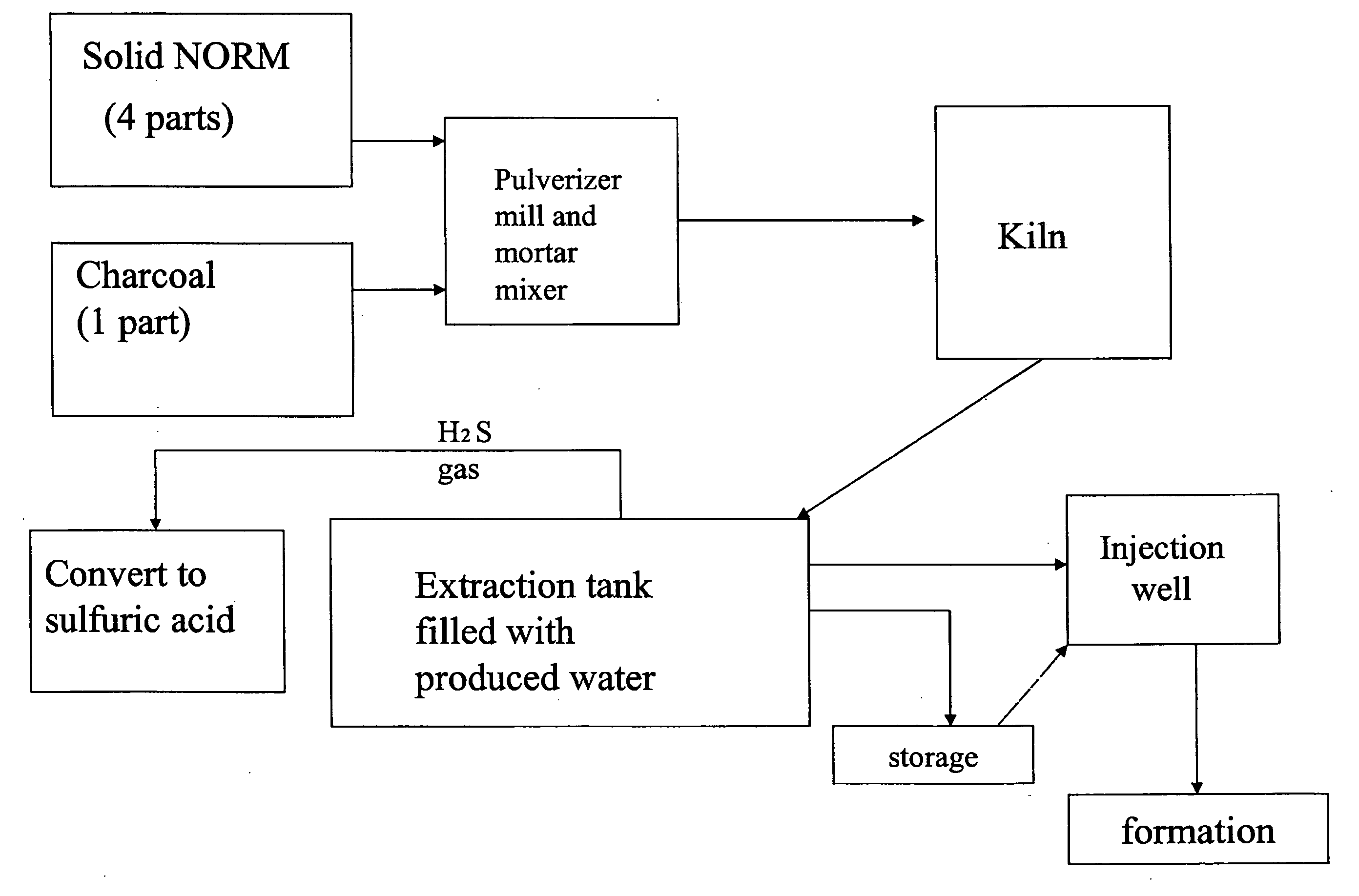

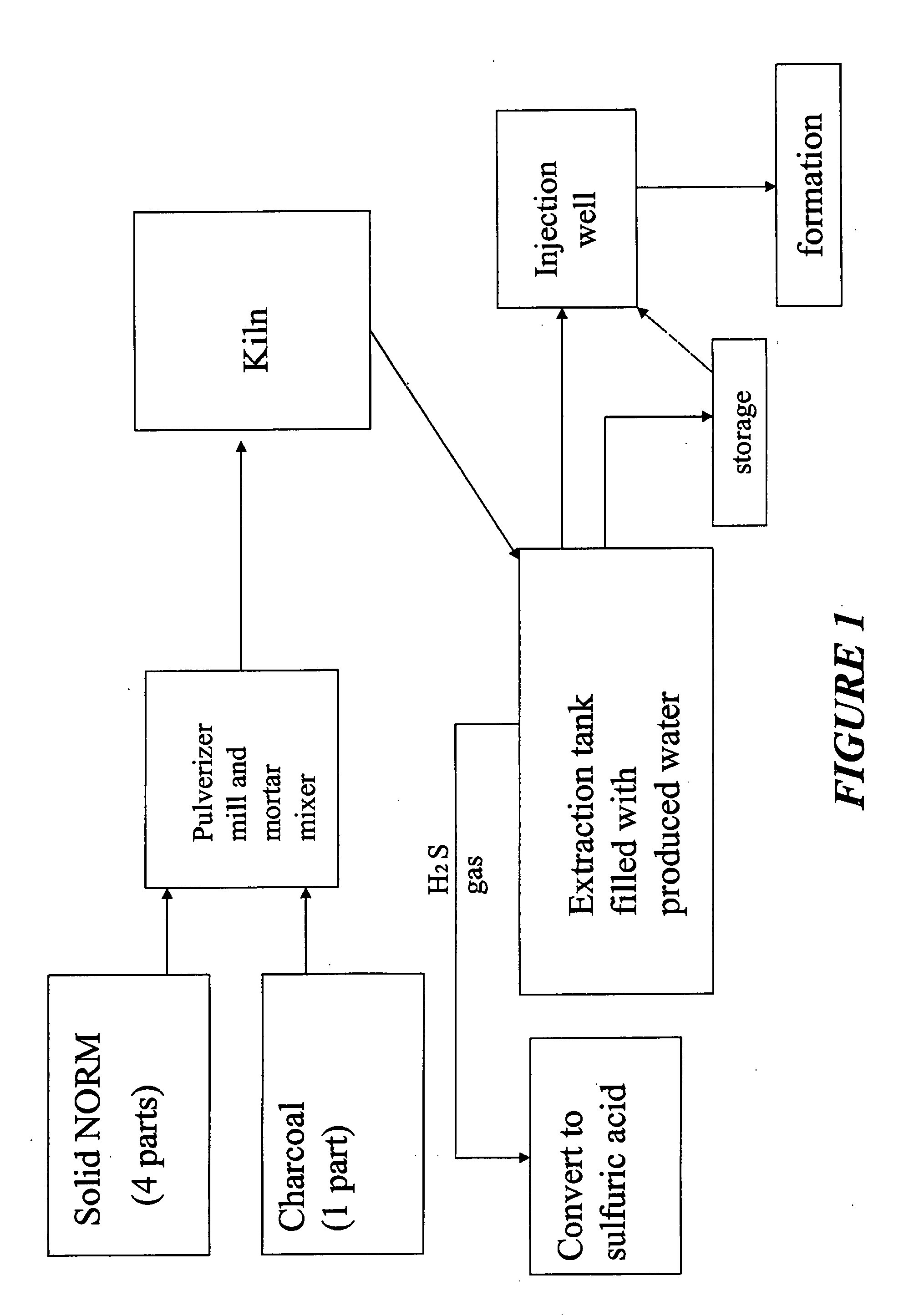

Method used

Image

Examples

example 1

[0034]In this example, sludge and / or scale is treated with a process comprising the following steps:

[0035](1) Trash, if present, is separated from the sludge, washed, and surveyed. If the trash is below acceptable action levels, it can be disposed of as regular trash. The trash washings are handled as discussed in step (6), below.

[0036](2) The wet materials are passed through a rotating drum dryer.

[0037](3) The course particulates will be passed through a roller mill crusher that will break up the scale particles without significantly altering the much harder gravel-type material.

[0038](4) The product from the roller mill is screened (about 3 mm) to separate the gravel from the scale, sand, and soil material.

[0039](5) The gravel is washed and surveyed for radioactivity. When the gravel is below appropriate action levels, it is considered to be “clean,” and can be removed from the process

[0040](6) The washing water is allowed to settle in a holding tank, and the particulates are pass...

example 2

[0046]Example 1 is repeated, with the equipment needed arranged to allow a mobile treatment facility.

example 3

[0047]This Example demonstrates a “mobile” embodiment of the present invention.

[0048](A) Equipment Needed

[0049]1. Semi tractor and trailer with canvas sides on which the remaining equipment is installed or loaded for transport from site to site.

[0050]2. Five large commercially available walk-in pottery kilns, enclosed in airtight steel cabinets equipped with gas inlets and gas escape valves

[0051]3. Five nitrogen gas cylinders with regulators

[0052]4. Mortar mixer

[0053]5. Pulverizer mill

[0054]6. Small front loader

[0055]7. 25 stackable ceramic crucibles, 100 gallon capacity

[0056]8. 2 extraction tanks, 1000 gallon capacity

[0057]9. Water pump and hose

[0058]10. Gieger-Mueller counter

[0059](B) Procedure

[0060]1a. If the scale or sludge contains significant amounts of trash, e.g. plastic sheeting, protective clothing, etc., and when governmental regulations prevent incineration of such materials, suspend the material in a tank of water or brine, the trash may be removed with a paddle, rinsed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com