Silt fence apparatus and method of construction

a technology of silt fences and fences, applied in foundation engineering, excavations, construction, etc., can solve the problems of large areas of soil mounds which may lay undisturbed for several months, severe run-off, contaminating streams, etc., and achieves less subject matter, less strength, and more economical construction and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

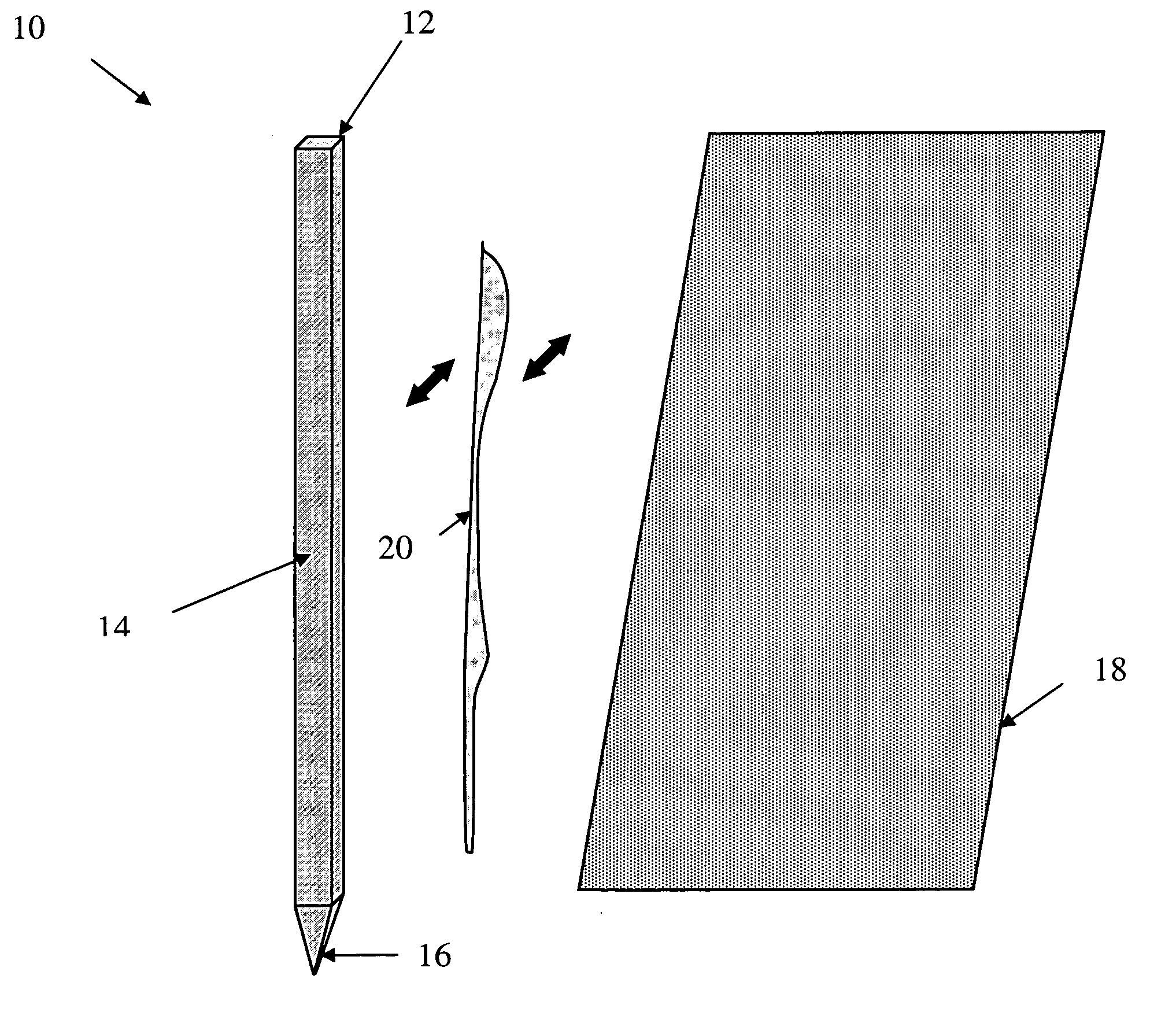

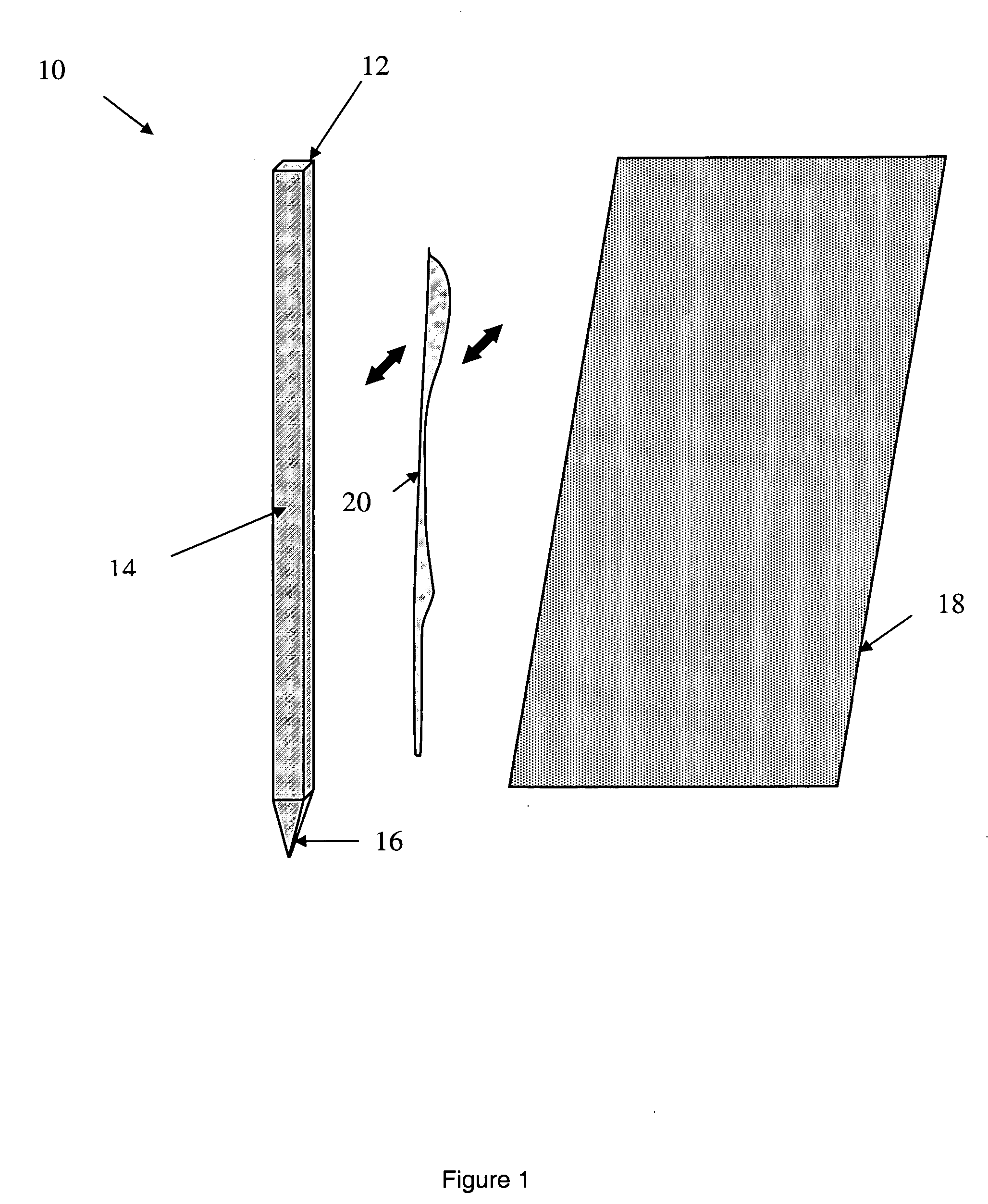

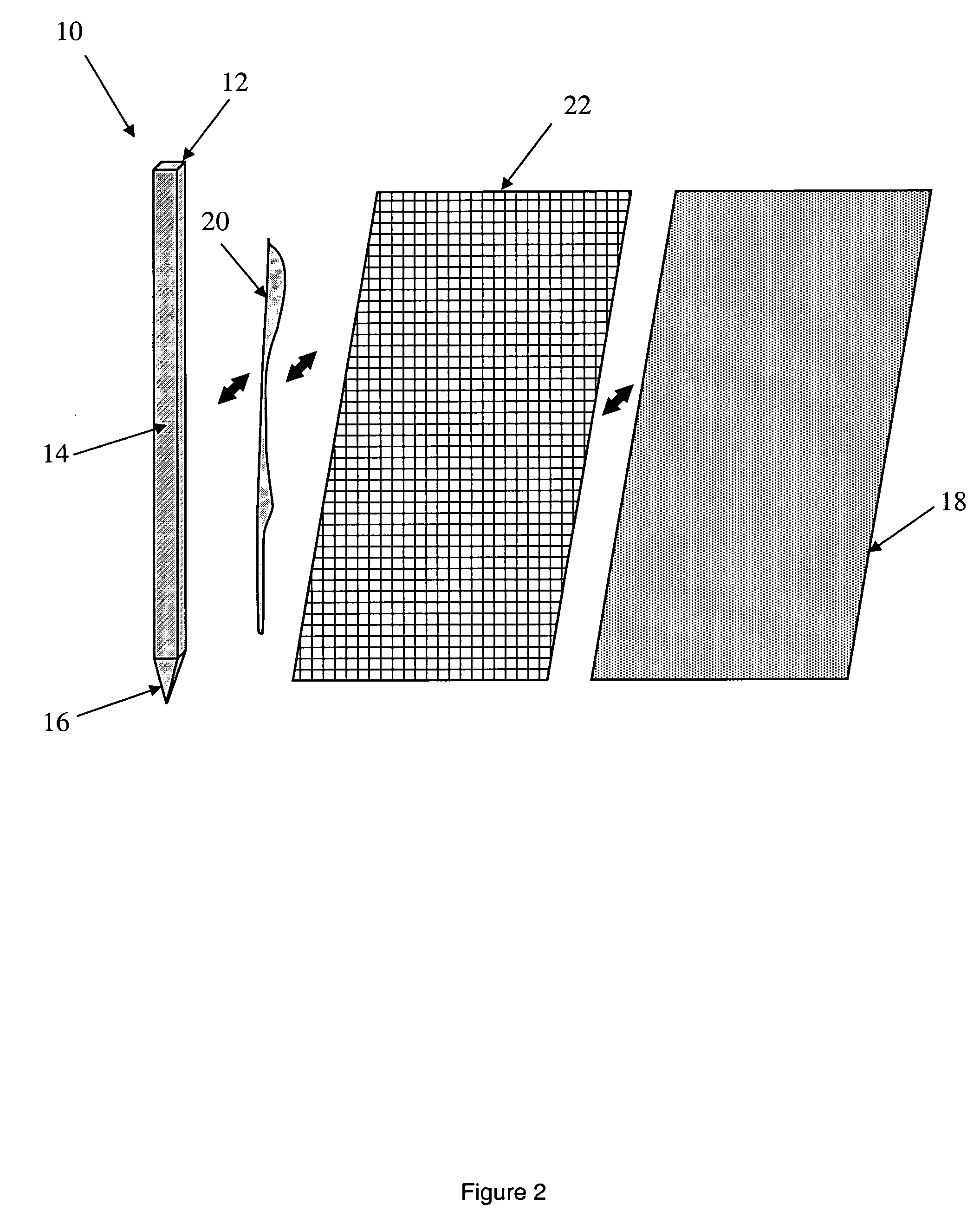

[0031]FIGS. 1-4 illustrate a silt fence assembly 10 in accordance with the invention. The silt fence assembly 10 includes a plurality of support stakes 12, preferably made from plastic, each of which consists of a longitudinal body portion 14 terminating in a pointed end 16 so that the pointed end 16 may be penetrated into the ground surface for anchoring the plurality of support stakes 12 in an upright position. Although the preferred embodiment is a plastic material for the support stake 12, it is understood that the support stake 12 may be fabricated of any plastic, metal, wood, or wood composite material or size of any convenient cross-section as dictated by the specific application.

[0032] As also illustrated in FIGS. 1-4, the silt fence assembly 10 includes a web or silt fabric screen 18 of any suitable woven polymeric fabric. Woven silt fabrics using synthetic yarns have been used increasingly in recent years to prevent soil run-off at construction sites. These fabrics are ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com