Method, System, and Apparatus for Modular Central Plant

a technology of modular central plants and methods, applied in the field of methods, systems and apparatus for modular central plants, can solve the problems of increasing the cost of design, delivery and installation of a central plant, requiring substantial mechanical construction, field assembly and system integration effort, and the overall cost of building construction, so as to improve the system maintainability, reduce the system cost and assembly time, and improve the effect of scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

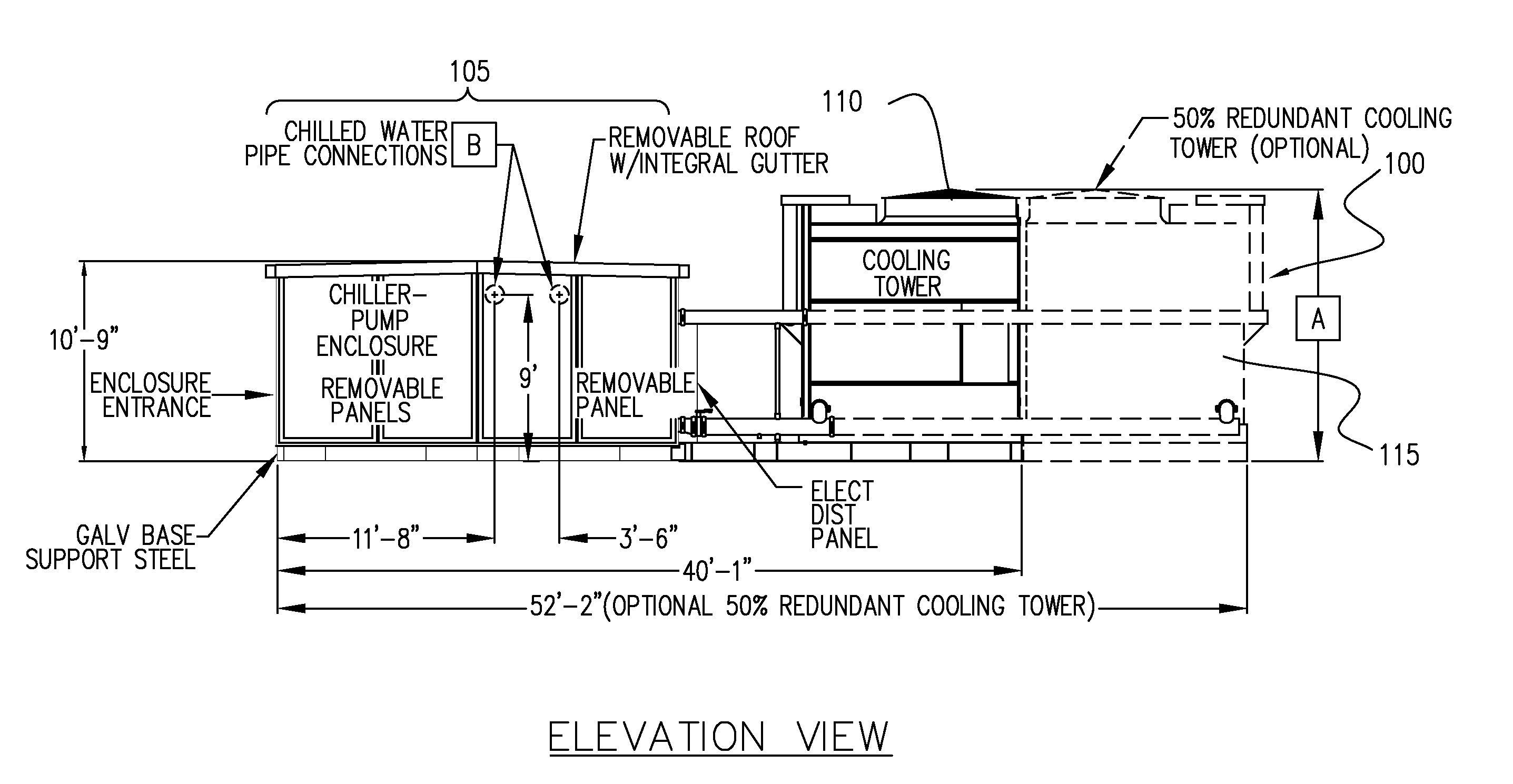

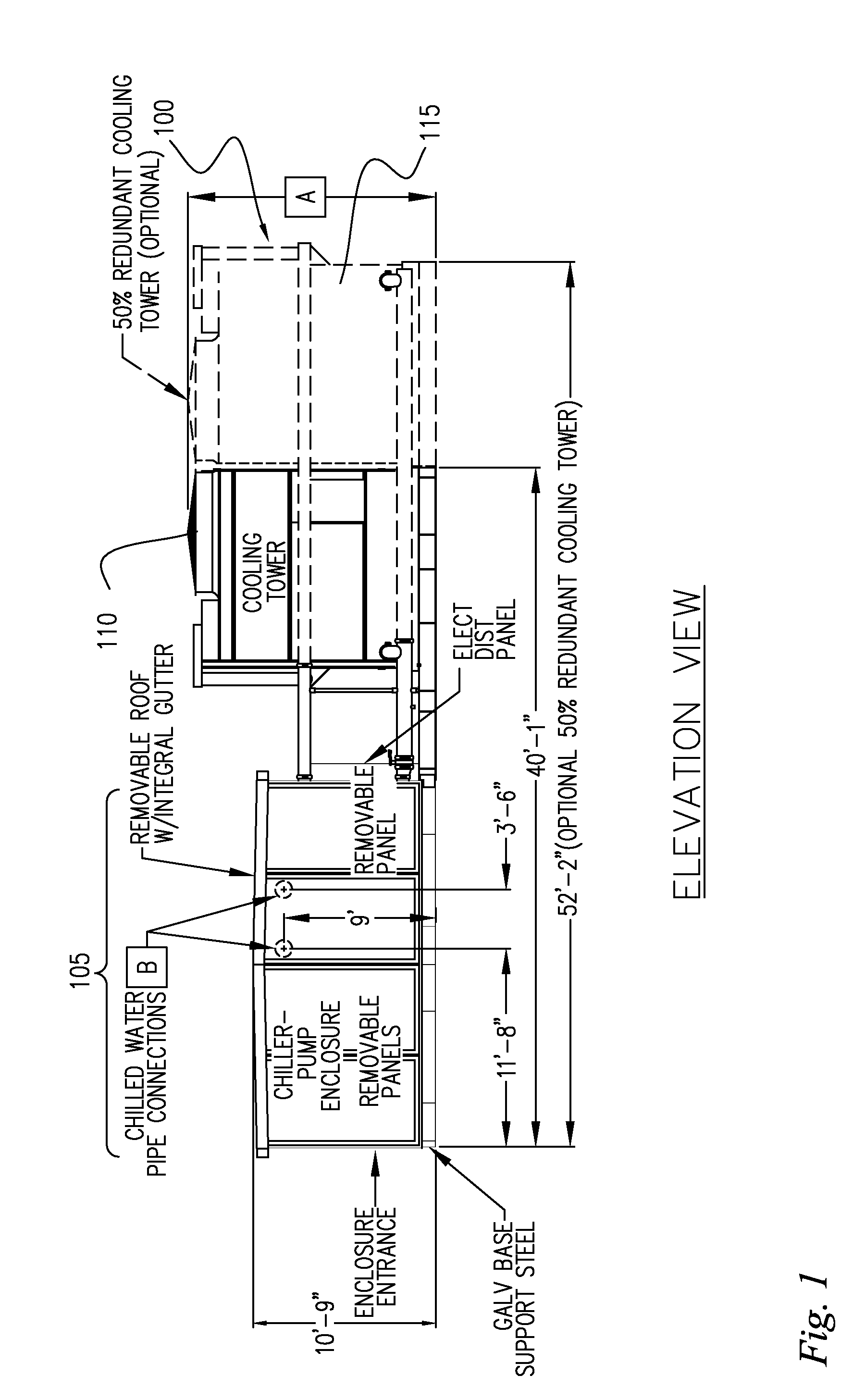

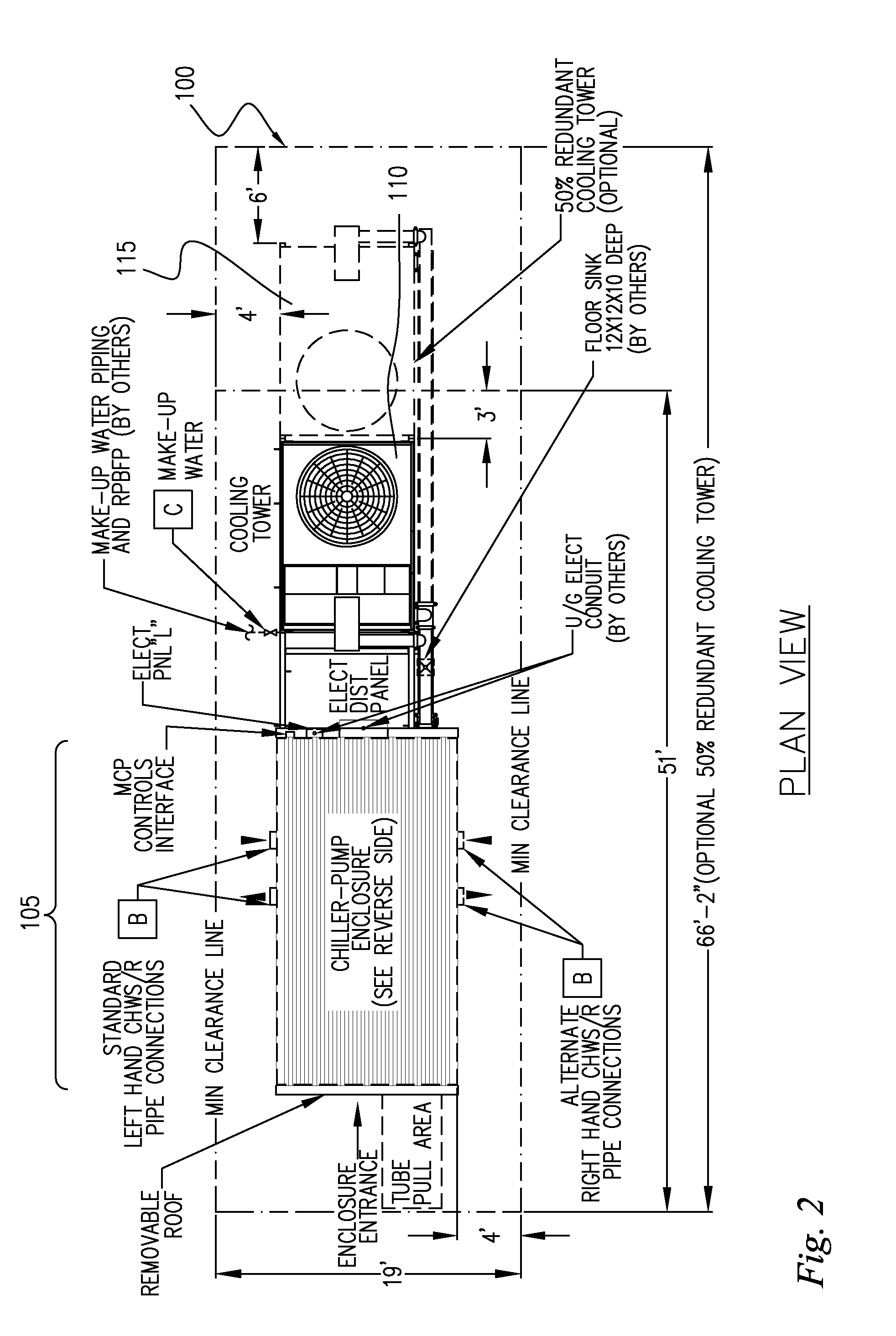

[0054]Referring to FIGS. 1 and 2, an exemplary integrated chiller-tower module 100 is shown in elevation view and plan view, respectively. In one embodiment, the integrated chiller-tower module 100 comprises a modular chiller unit 105 interconnected to a cooling tower 110. An optional additional cooling tower 115 may also be provided. FIGS. 3 and 4 show respective elevation and plan views of the chiller module 105, with removable roof panels and side panels removed to illustrate internal components and placement of piping at connection interfaces at the sides of the chiller module. Commercially available components may be utilized in the present invention to further improve cost efficiency and performance.

[0055]The modular chiller-tower units, once assembled at the jobsite and connected to building services, are fully self-contained and capable of independent operation. In one embodiment of the present invention, no additional controls or building automation systems are needed to br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com