Inorganic/organic dispersant and application thereof

a technology of inorganic/organic dispersant and dispersant, applied in the field of i/o (inorganic/organic) dispersant, can solve the problem of unstable dispersant with aggregation, and achieve the effect of dispersing nanoparticles of metal oxid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

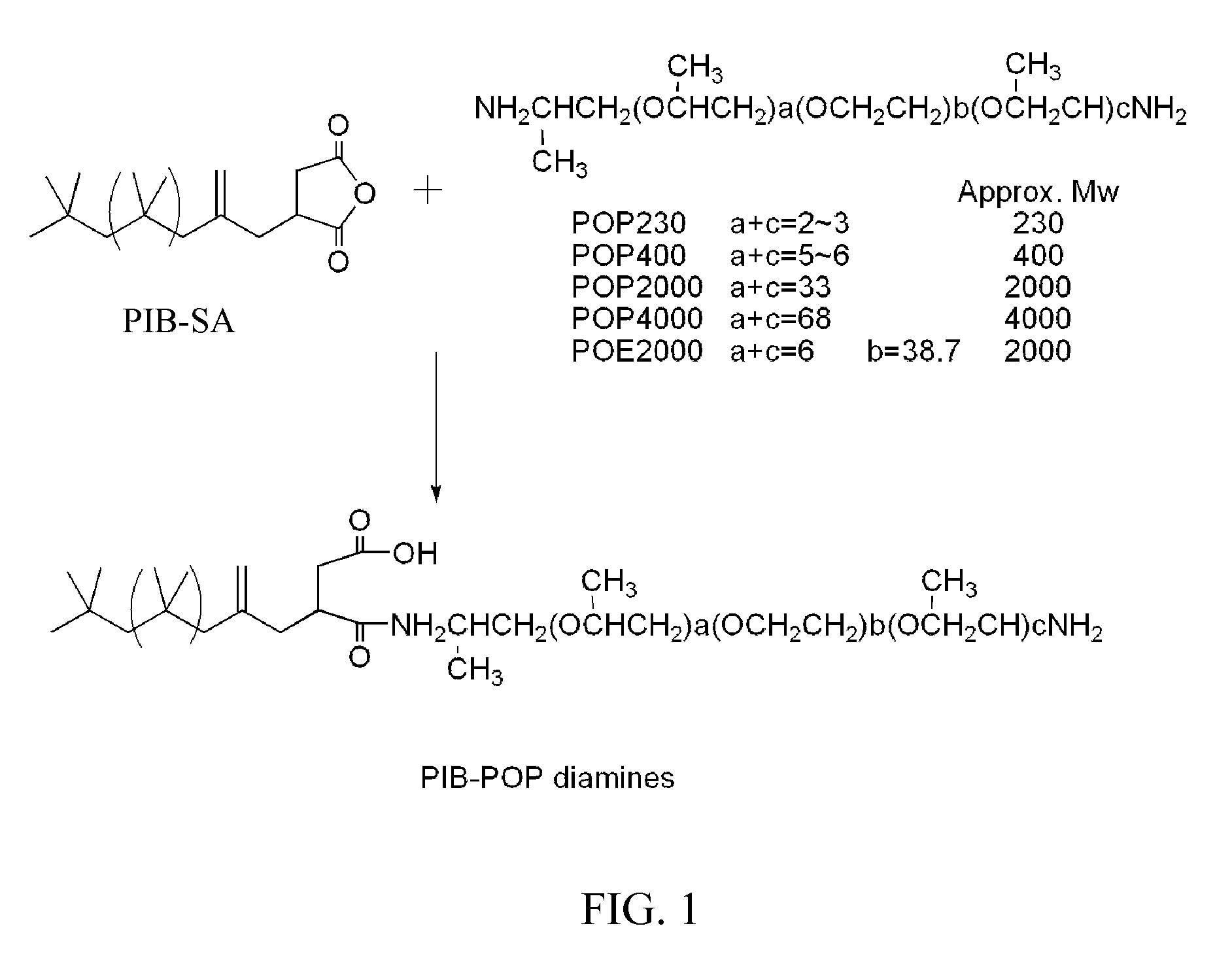

Method used

Image

Examples

example 1

[0026]Step (a): Na+-montmorillonite (MMT) (10 g) is first dispersed in water (1 L) at 80° C. and then vigorously stirred for 4 hours to obtain a stable earth-colored dispersion.

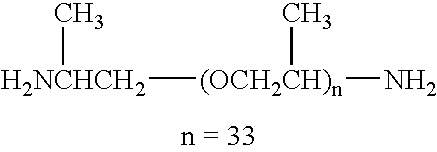

[0027]Step (b): The polyoxypropylene diamine of Mw 2000 (D2000) (24 g, 12 mmol, CEC ratio of D2000 / MMT=1.0) is dissolved in ethanol (100 ml), and equivalent moles of hydrochloric acid is added therein for acidification for 30 minutes. The acidified intercalation solution is added to the Na+-MMT dispersion slowly and stirred at 60˜70° C. for 6 hours for a cation exchanging reaction. Then the resultant reaction solution is separated into two phases. After filtration, the residual is washed with water for several times to remove the unreacted organics and the inorganic clay. The synthesized product (D2000 / MMT hybrid) was analyzed to have an organic / inorganic weight ratio 74 / 26 and can be further dried in a vacuum oven at high temperature for 24 hours.

example 4

[0029]Step (a): Na+-MMT (10 g) is first dispersed in water (10 L) at 80° C. and then vigorously stirred for 4 hours to obtain a stable earth-colored dispersion.

[0030]Step (b): P-cresol (27.2 g) and D2000 (757.6 g) are weighted with a molar ratio 2:3 and circulated in toluene at 90° C. for 3 hours. Then a formaldehyde solution (37 wt %, 61.4 g) is added and the temperature is raised to 130° C. for reaction for 5 hours. When a gel is formed, the reaction is stopped and the product, an intercalating agent AMO (Amine-termination Mannich Oligomer), can be obtained. The AMO is analyzed with GPC and three peaks are found at Mw=3,142, 6,221 and 9,246, respectively. Results of amino titration are that primary amine=0.4 meq / g, secondary amine=0.56 meq / g, and no tertiary amine is found. Then the AMO is dissolved into water (575 g) and mixed with concentrated hydrochloric acid (35 wt %, 36 g) at 80° C. for 30 minutes to acidify the AMO. The acidified AMO is poured into the above Na+-MMT dispers...

example 5

[0036]Repeat Step (a) and Step (f) of Example 4, but NSP is replaced with MMT in Step (f). Then the product (ODA / MMT) with an organic / inorganic weight ratio 70 / 30 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| amphoteric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com