2,5-di(methoxyanilino) terephthalic acid polymorphs and quinacridones realized therefrom

a technology of terephthalic acid and dimethoxyanilino, which is applied in the field of new crystal types of 2, 5di (pmethoxyanilino) terephthalic acid, can solve the problems of lack of evidence in the literature that the 2,5-dianilinoterephthalic quinacridone and the precursor of quinacridones exhibit polymorphism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 (

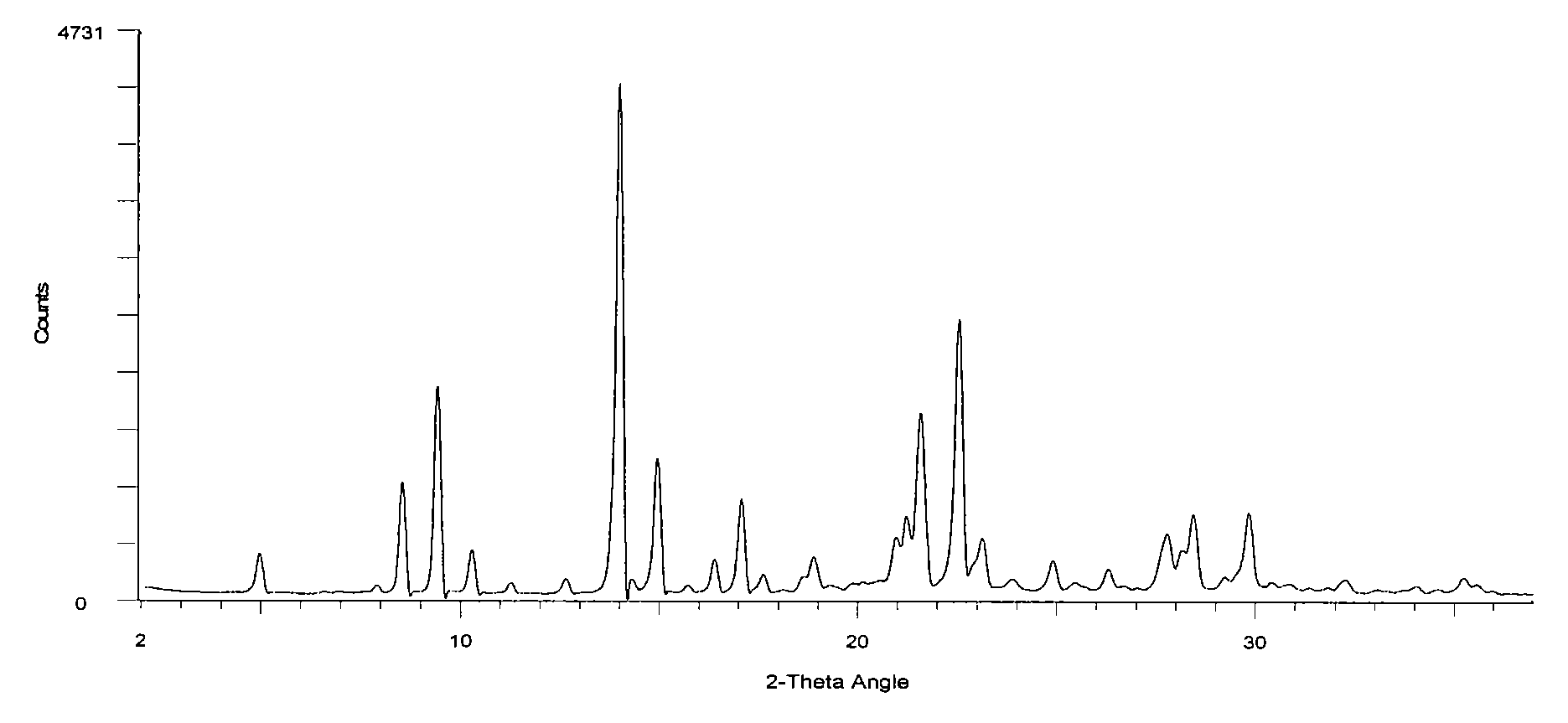

CRYSTAL TYPE I)

[0028]To a pressure reactor were charged 489.8 g of methanol. With agitation, 50 g of dimethylsuccinyl succinate were charged and stirred for ˜10 minutes. To the stirring slurry were added 56.7 g of p-anisidine. After stirring for ˜15 minutes, 0.8 g of 96% H2SO4 were added dropwise. The reactor was sealed, heated to 95-100° C. and held at this temperature for approximately 5 hours. After cooling to 40-50° C., the reactor was opened and with agitation, 55.6 g of m-nitrobenzenesulfonic acid, sodium salt, were added. After stirring for ˜5 minutes, 127.8 g of 45% KOH were charged over a 15 minute period. The reactor was sealed, heated to 90-95° C. and held at this temperature for approximately 4 hours. Upon cooling to 40-50° C., the reaction slurry was transferred to a container containing 800 g of H2O. Once the transfer was complete, an additional 275 g of H2O were added and with stirring, the solution was heated to 30-40° C. The pH was then adjusted from 13 to 7.5-7.0 w...

example 2 (

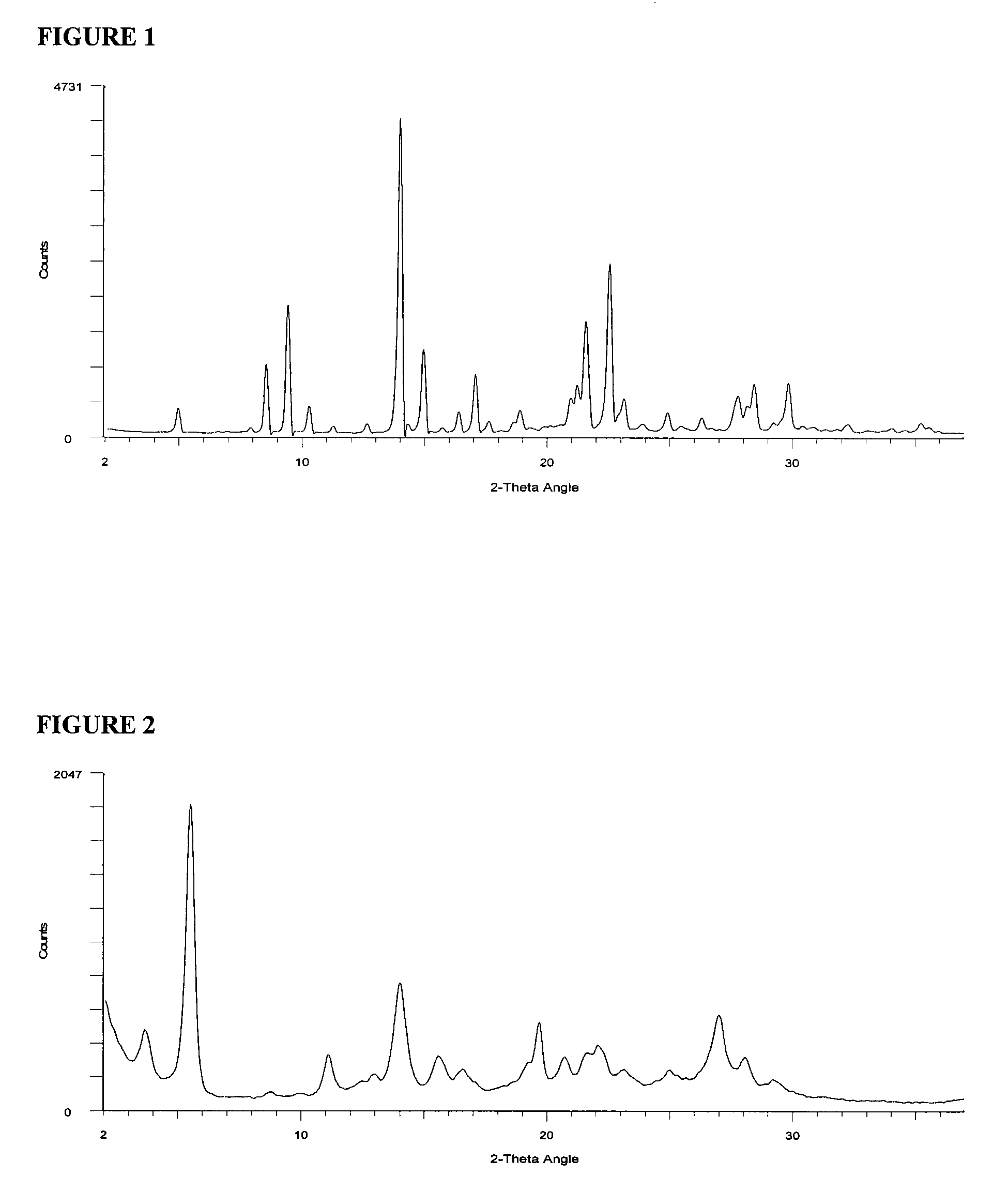

CRYSTAL TYPE II)

[0030]To a pressure reactor were charged 489.8 g of methanol. With agitation, 50 g of dimethylsuccinyl succinate were charged and stirred for ˜10 minutes. To the stirring slurry were added 56.7 g of p-anisidine. After stirring for ˜15 minutes, 0.8 g of 96% H2SO4 were added dropwise. The reactor was sealed, heated to 95-100° C. and held at this temperature for approximately 5 hours. After cooling to 40-50° C., the reactor was opened and with agitation, 55.6 g of m-nitrobenzenesulfonic acid, sodium salt, were added. After stirring for ˜5 minutes, 127.8 g of 45% KOH were charged over a 15 minute period. The reactor was sealed, heated at 90-95° C. and held at this temperature for approximately 4 hours. Upon cooling to 55-65° C., the reaction slurry was transferred to a container using water to a total volume of 1200 mL. The solution was held 15 minutes at 55-65° C., then transferred over 45-60 minutes, via a pump, to a vessel containing 1344 g of a 3.6% HCl solution. The...

example 3

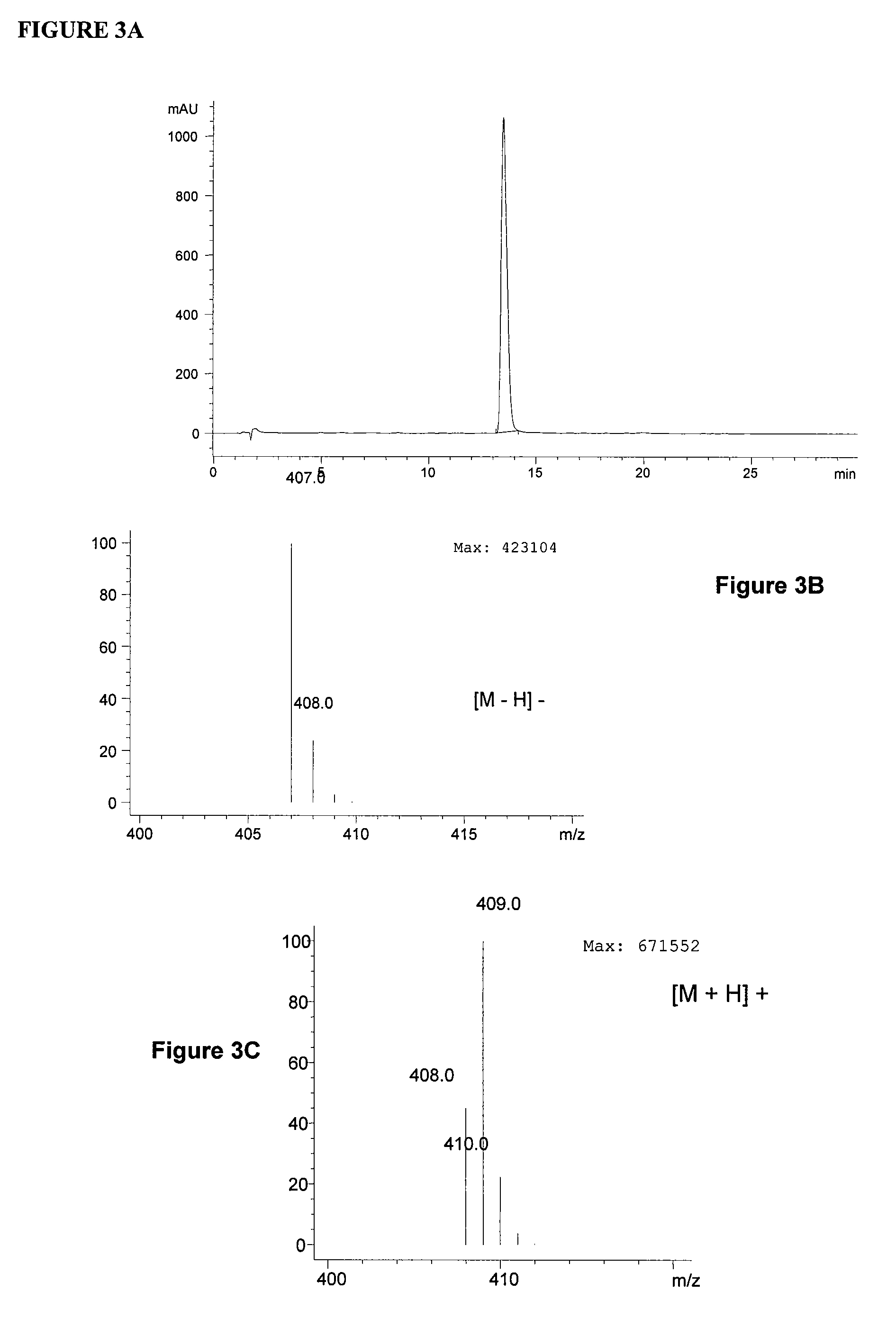

[0033]A portion of the brown product of Example 1 (50 g) was dissolved in water having a basic pH (955 g water and 75.2 g 45% KOH). The resulting solution was stirred for 55-65° C. for 60 minutes and then allowed to cool to 35-40° C. The pH was then adjusted from 12.8 to 5.3 with 31.7 g 96% H2SO4. The resulting violet slurry was stirred for 60 minutes at 35-40° C., at which time it was filtered and the resulting presscake washed with water until conductivity free (<120% of incoming wash water). The washed presscake was then dried in an oven to obtain 43 g of violet powder. When evaluated by HPLC, the purity profile was 93.3% 2,5-di(p-methoxyanilino)terephthalic acid. Evaluation by LC-MS confirmed that the major component was indeed 2,5-di(p-methoxyanilino)terephthalic acid. The mass spectra (FIGS. 5A to 5C) and X-ray diffraction pattern (FIG. 6) confirms that the violet type intermediate was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com