Urea solution tank assembly

a technology of urea solution and tank, which is applied in the field of tanks, can solve the problems of reducing the service life of the tank, and achieve the effect of convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

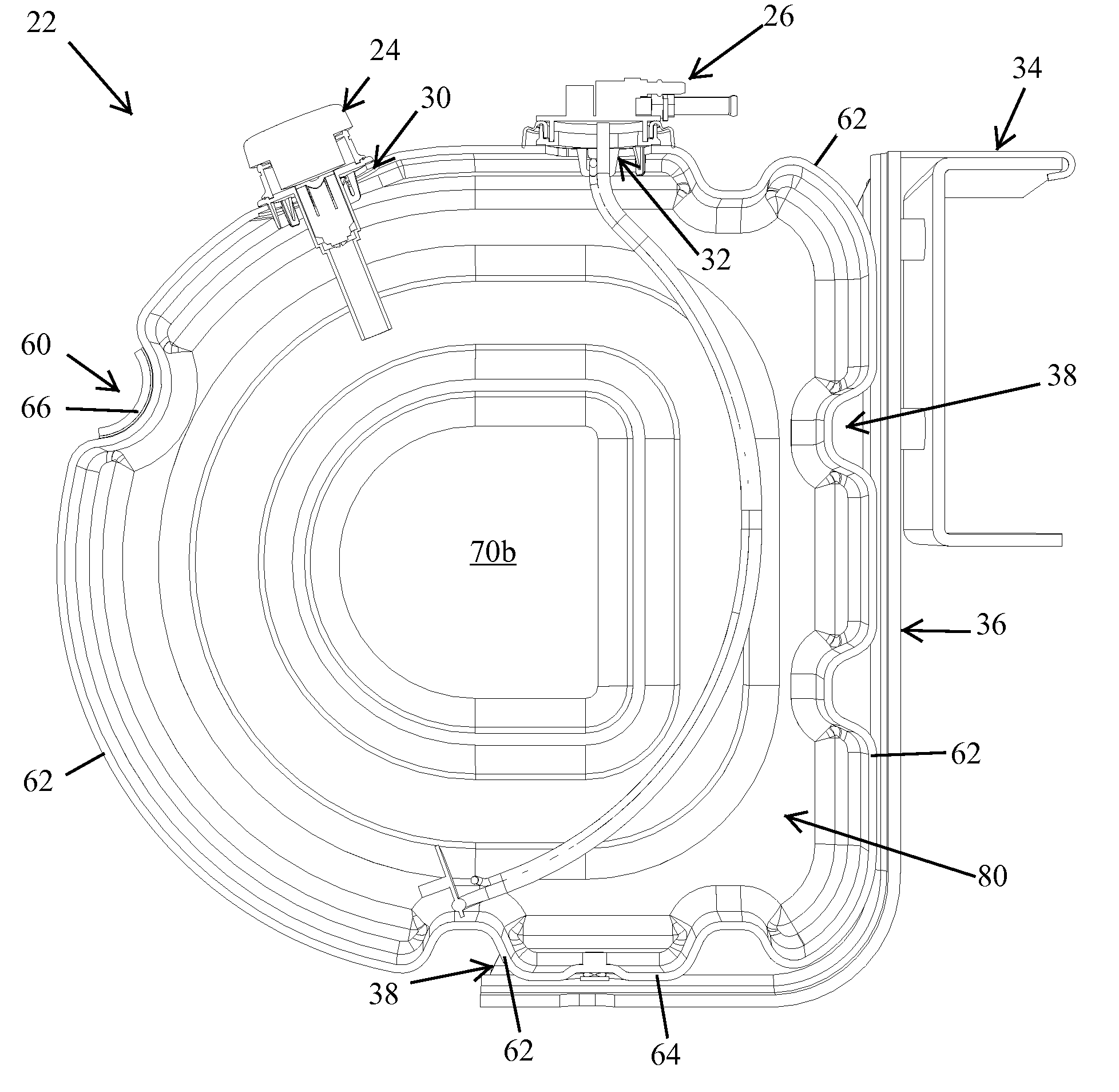

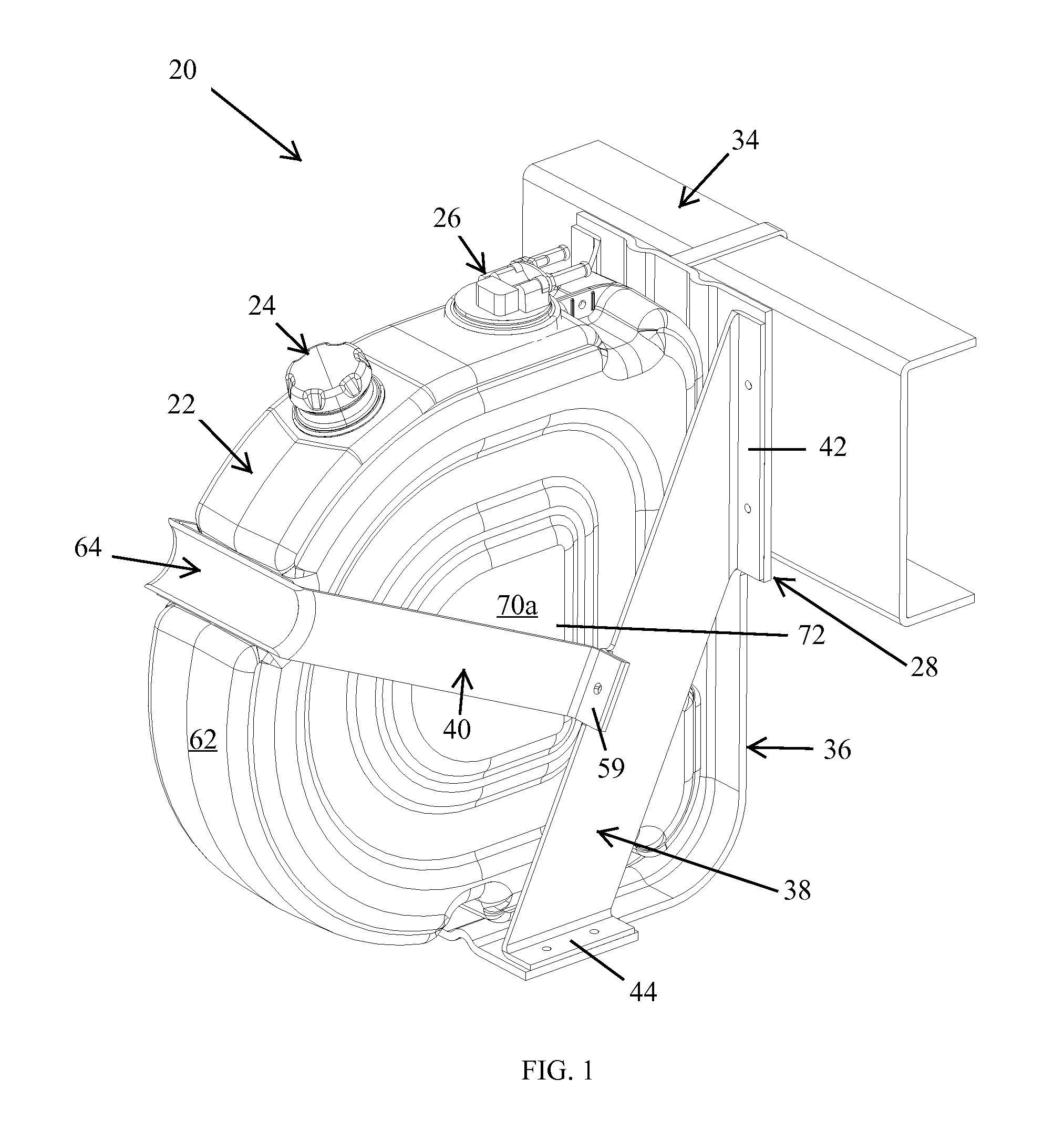

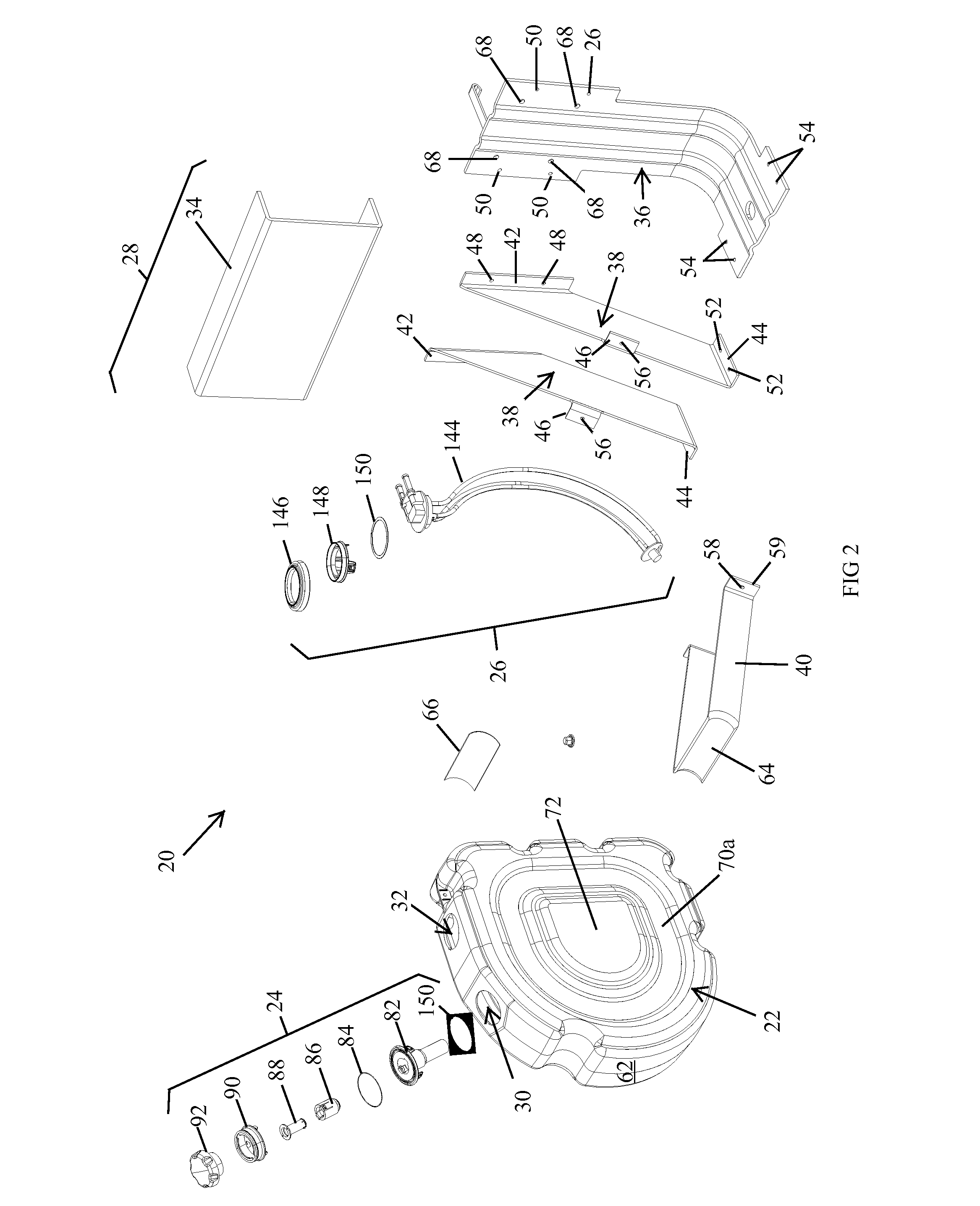

[0058]A tank assembly 20 according to a first embodiment of the present invention is illustrated in FIG. 1. Tank assembly 20 includes a tank 22 for storing a urea solution, a filler tube assembly 24, a sensor unit assembly 26, and a bracket system 28. Filler tube assembly 24 is adapted to allow urea solution to be delivered to tank 22 through a first aperture 30 (FIG. 2). Sensor assembly 26 is adapted to sense the level of urea solution within tank 22, as well as to allow urea solution to be pumped out of tank 22 through a second aperture 32 for delivery to a selective catalyst reduction (SCR) system (not shown), which may be located on a motorized vehicle as part of a nitrogen oxide (NOx) emission reduction system for the motorized vehicle. Alternatively, in at least one embodiment, the SCR system may be utilized to help reduce the emissions from a stationary source of NOx, and tank assembly 20 may thus be mounted in a stationary location, rather than on a motorized vehicle. Regard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com