Anticorrosive composition

a composition and anticorrosion technology, applied in the field of anticorrosion agents, can solve the problems of ineffective control of the corrosivity of the brine by the additives, the use of deicing formulations, and the high cost of various additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The present invention relates to the discovery that melanoidins, and higher molecular weight fractions of products containing melanoidins, provide significant corrosive inhibition, which render these melanoidins suitable for use as anticorrosive agents in corrosive environments.

[0016]Melanoidins are brown-colored polymers formed by the interaction of amino acids and carbohydrates (e.g., mono-, di-, and oligosaccharides). Melanoidins are formed by a reaction between carbohydrates / saccharides and amino acids during aqueous processing at elevated temperatures (e.g., 70 to 120° C.). This is known as the Maillard Reaction which is a complex reaction with a network of consecutive and parallel chemical reactions.

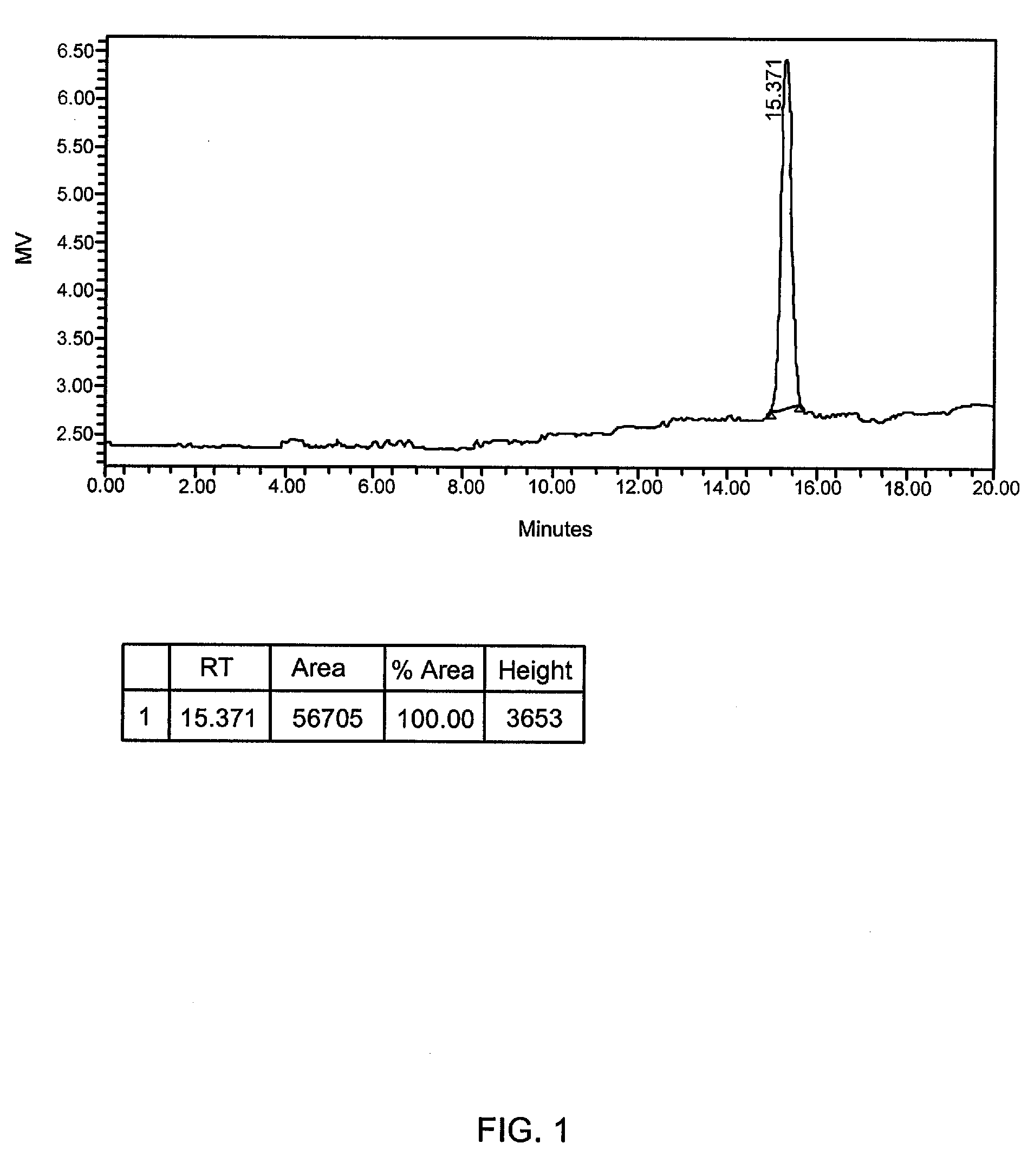

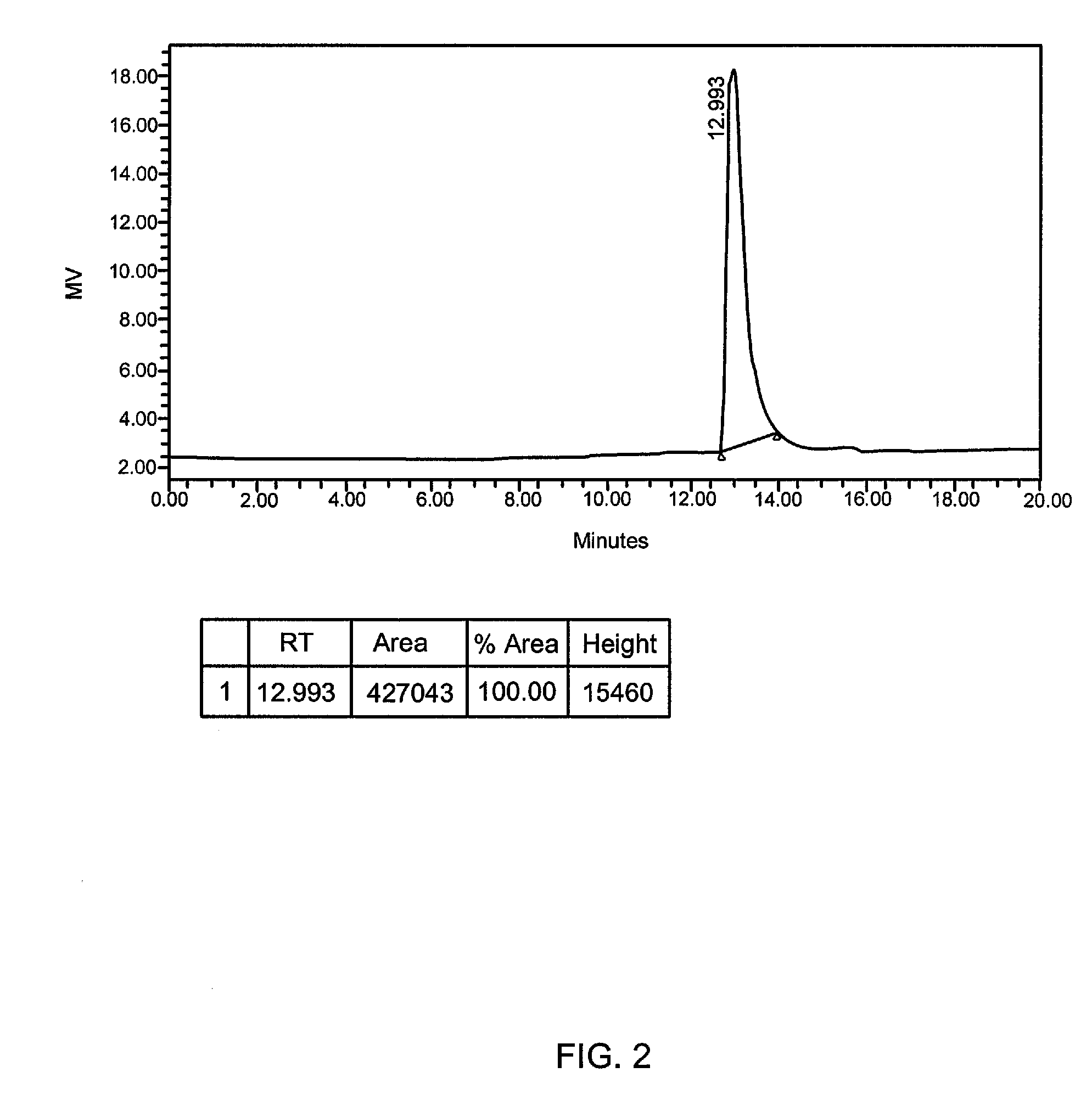

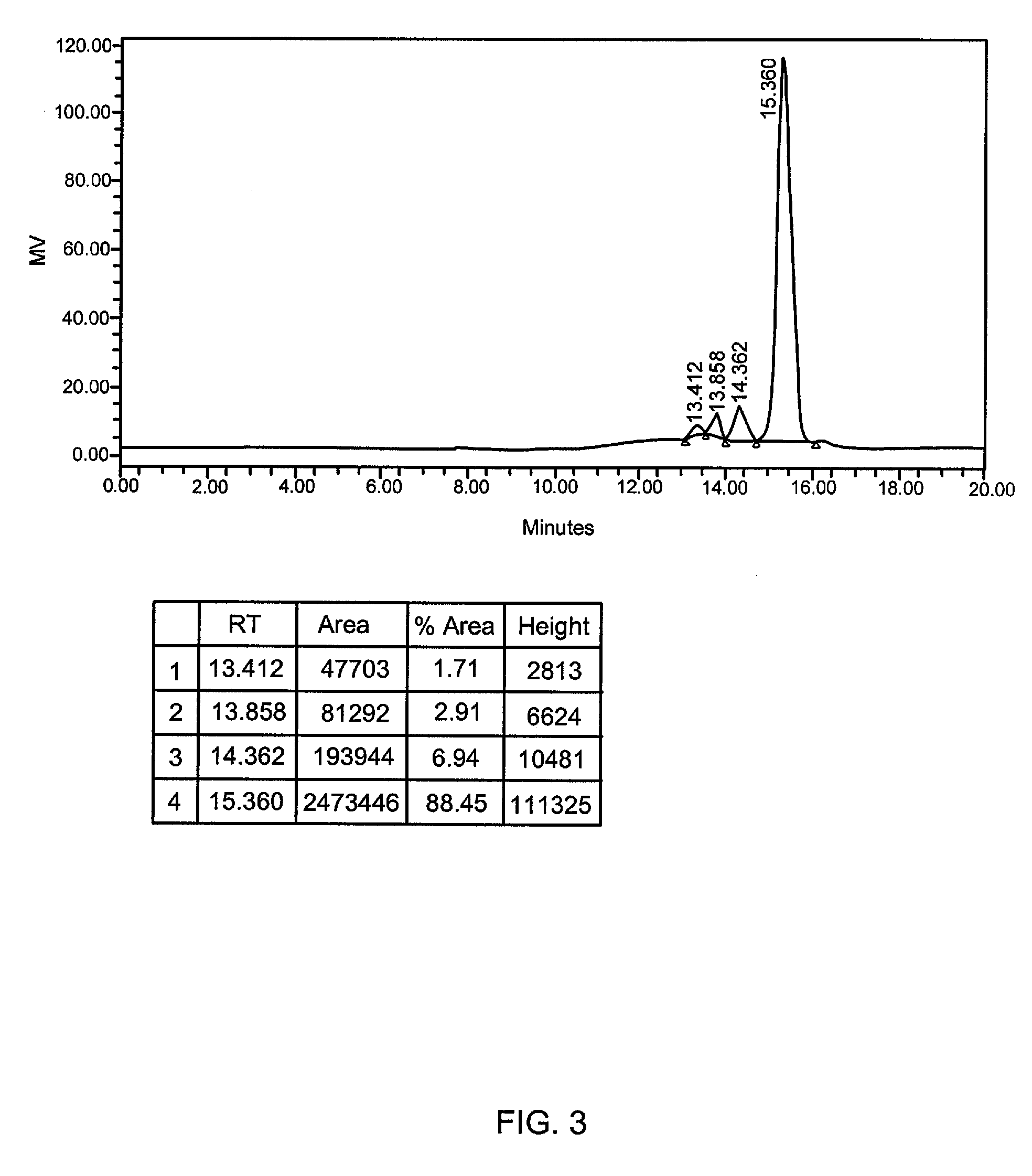

[0017]Although the molecular weights of melanoidins can vary from about 400 to more than 100,000 depending upon reaction conditions (e.g., temperature, time, pH, water content), the molecular weight of the melanoidins suitable for use in the present invention is above about 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com