Prerefining Process for the Hydrodesulfurization of Heavy Sour Crude Oils to Produce Sweeter Lighter Crudes Using Moving Catalyst System

a technology of moving catalyst and heavy sour crude oil, which is applied in the petroleum industry, hydrotreatment process, hydrocarbon oil cracking, etc., can solve the problems of affecting the activity of hydro-desulfurization catalyst, and high concentration of coke precursors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

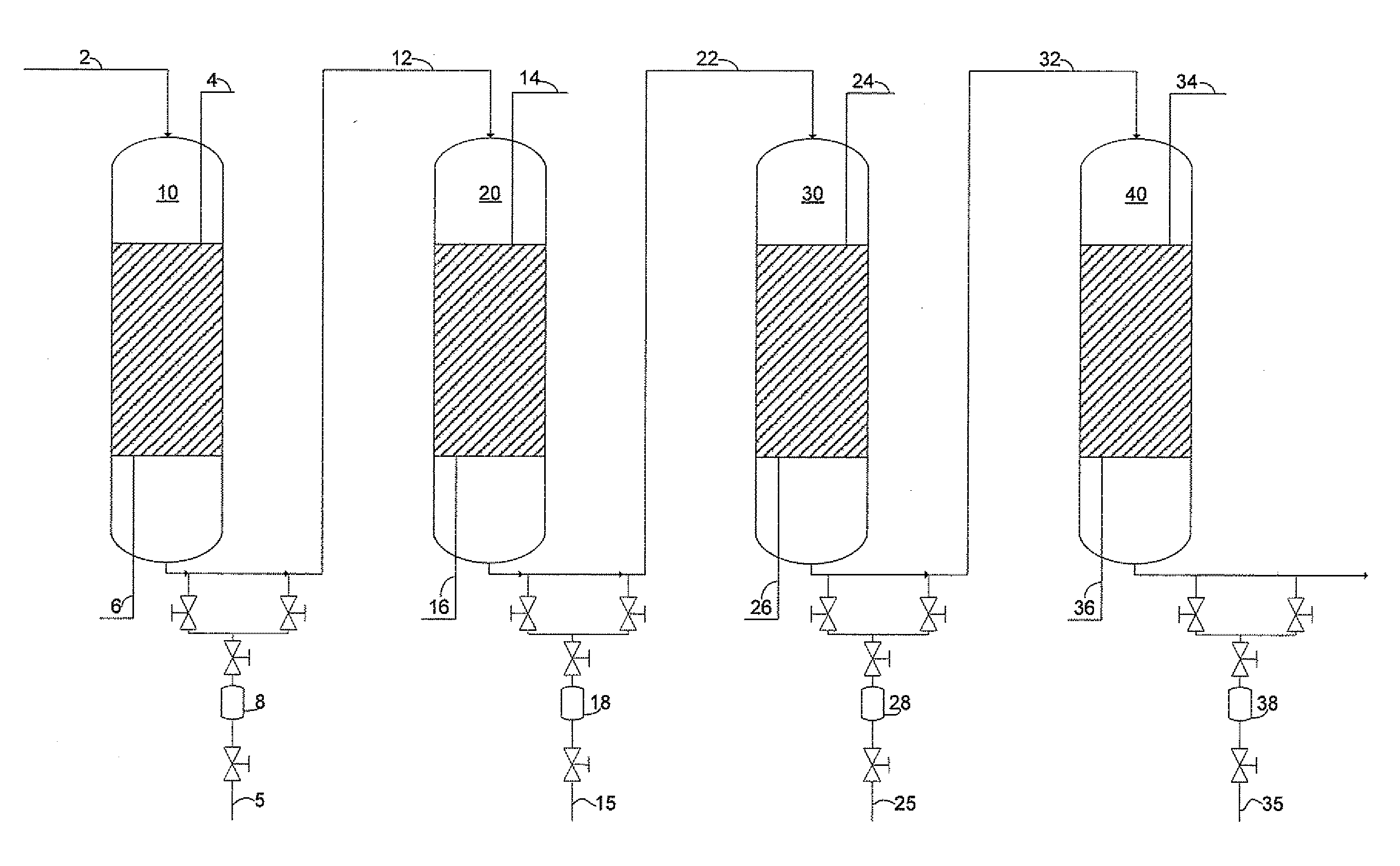

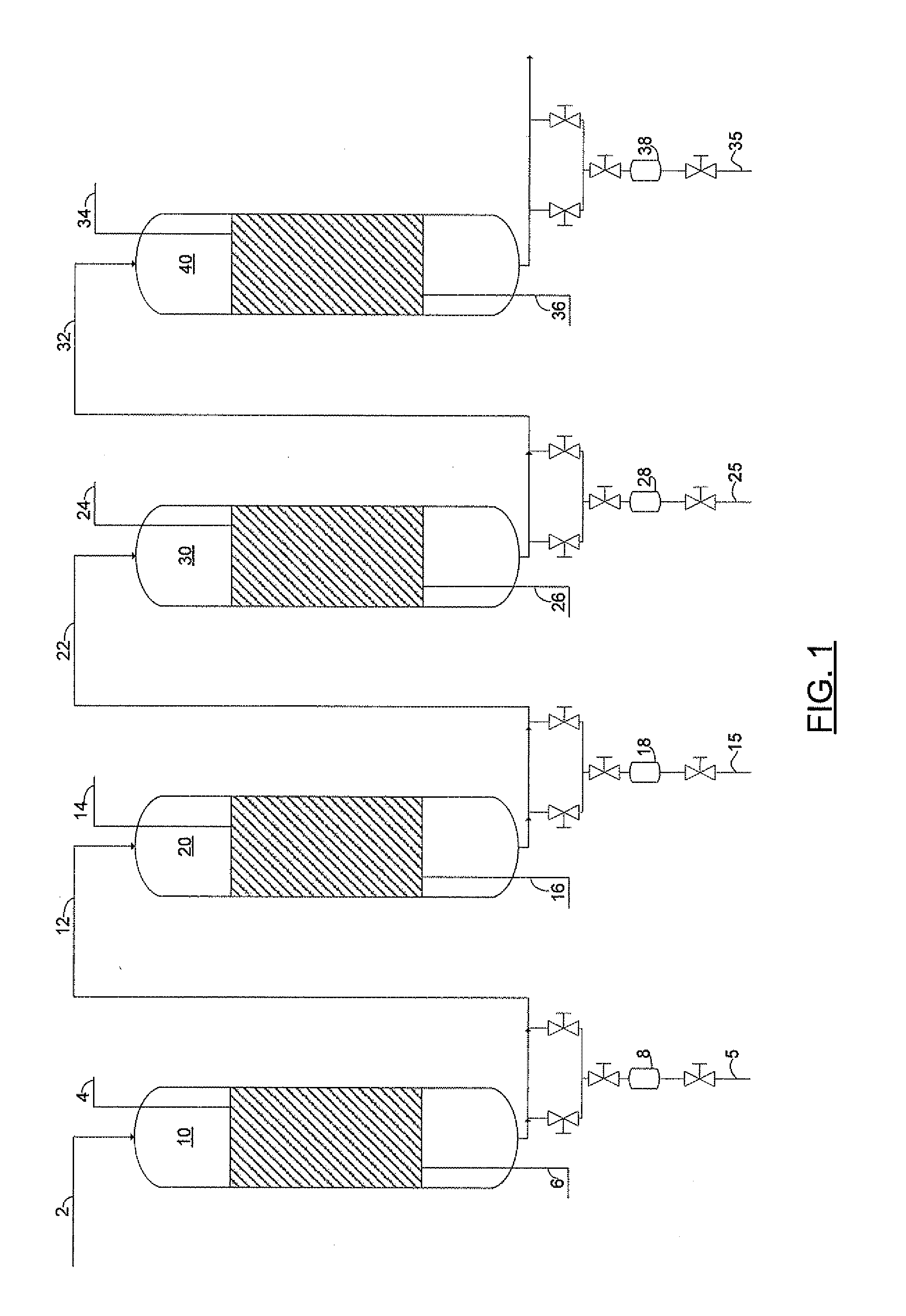

Image

Examples

example

Production of Low Sulfur Crude Oil

[0036]An Arab Heavy Feedstock having properties as shown in Table I below was processed in accordance with an embodiment of the present invention.

TABLE IProperties of Arab Heavy FeedstockCrude OriginUnitsArabian Heavy ExportDensity at 15° C.g / ml0.89API Gravity°27CCRwt %8.2Vanadiumwtppm56.4Nickelwtppm16.4Sulphurwt %2.83NaCl contentwtppmCwt %84.9Hwt %11.89

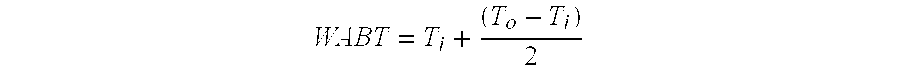

[0037]The specific conditions include the following: total hydrogen pressure of the reactor system is maintained at 100 bar; hydrogen to hydrocarbon ratio is maintained at 800 normal liters of hydrogen per liter of Arab Heavy Feedstock; temperature of the catalyst system was operated at between 370° C. and 380° C.; and the liquid hourly space velocity for the combined four reactors was 0.5 per hour. The Catalyst Replacement Rate for the first catalyst was maintained within the range of 0.05 to 0.5 weight percent of the total catalyst inventory per day. The Catalyst Replacement Rate for the third cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com