Absorption method for recovering gas contaminants at high purity

a gas contamination and high purity technology, applied in the field of gas separation methods, can solve the problems of difficult purification of contaminated gas, limited recovery of contaminated gas in a purified form, and inability to economically regenerate chemical solvents, etc., to achieve enhanced oil recovery, enhanced methane recovery, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

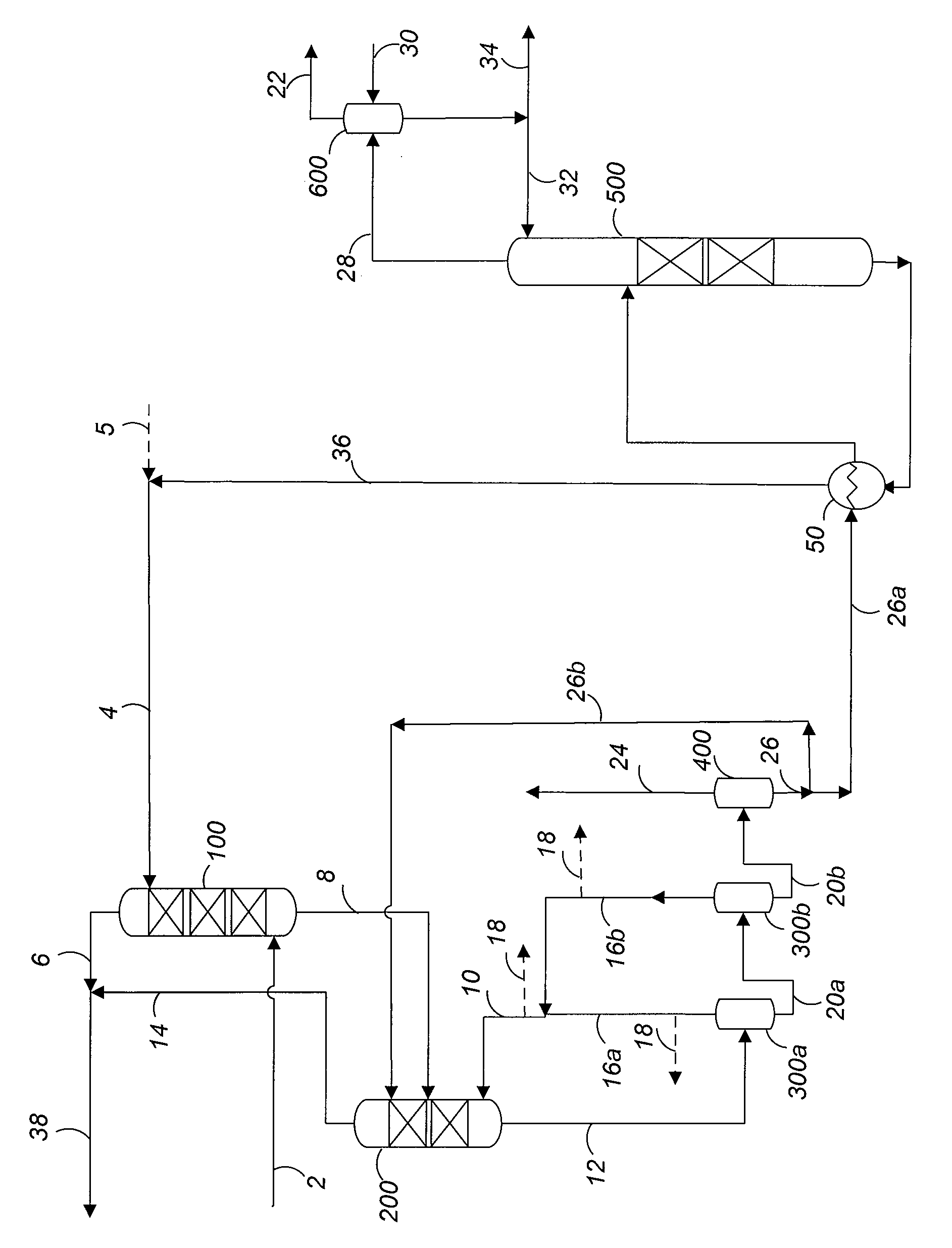

[0034]The two-stage gas purification process illustrated in FIG. 1 above was simulated using chemical process simulation software, namely ASPEN PLUS® (Aspen Technology, Inc., Burlington, Mass., USA) with a proprietary properties package. The model impure feed gas chosen for this simulation contained 95% and 5% by volume of methane and CO2, respectively. The physical solvent chosen was a commercial solvent used in the SELEXOL® process licensed by UOP, LLC (Des Plaines, Ill.), containing dimethyl ethers of propylene glycol.

[0035]The results of the simulation showed that more than 99.5% of the methane present in the impure feed gas could be recovered, in the combined, methane-enriched gas streams exiting the counter current absorber and stripper columns as vapor phases (i.e., the purified methane product gas). The combined stream, namely the methane product gas stream, had a methane purity of greater than 96.8% by volume on a water-free basis. Importantly, using the flowscheme in FIG. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com