Process for producing frozen confectionery products

a technology for producing confectionery products and hygienic process, which is applied in the direction of grain treatment, manufacturing tools, applications, etc., can solve the problems of affecting the quality of confectionery, so as to hinder the movement of confectionery, and reduce the rate of growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

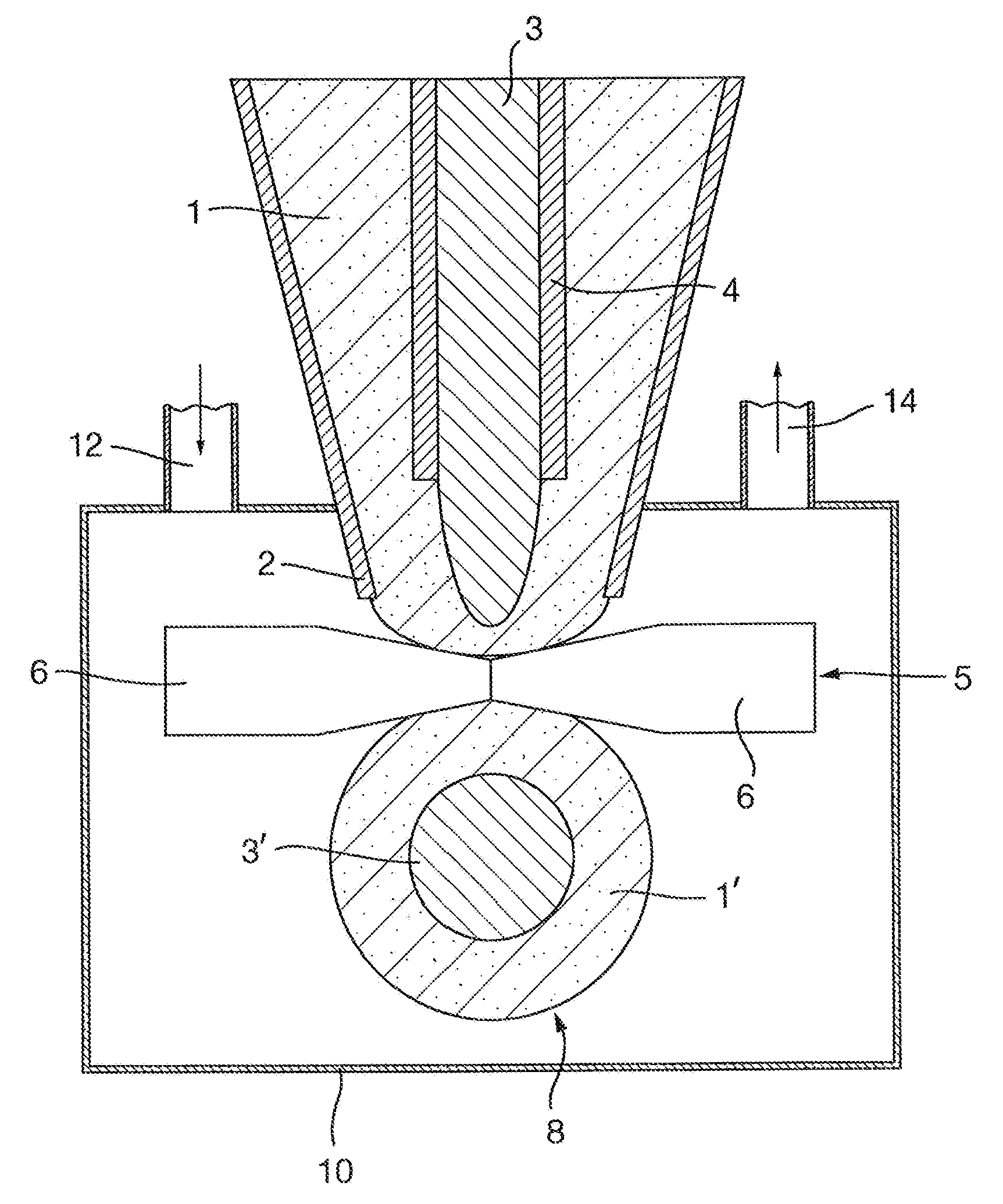

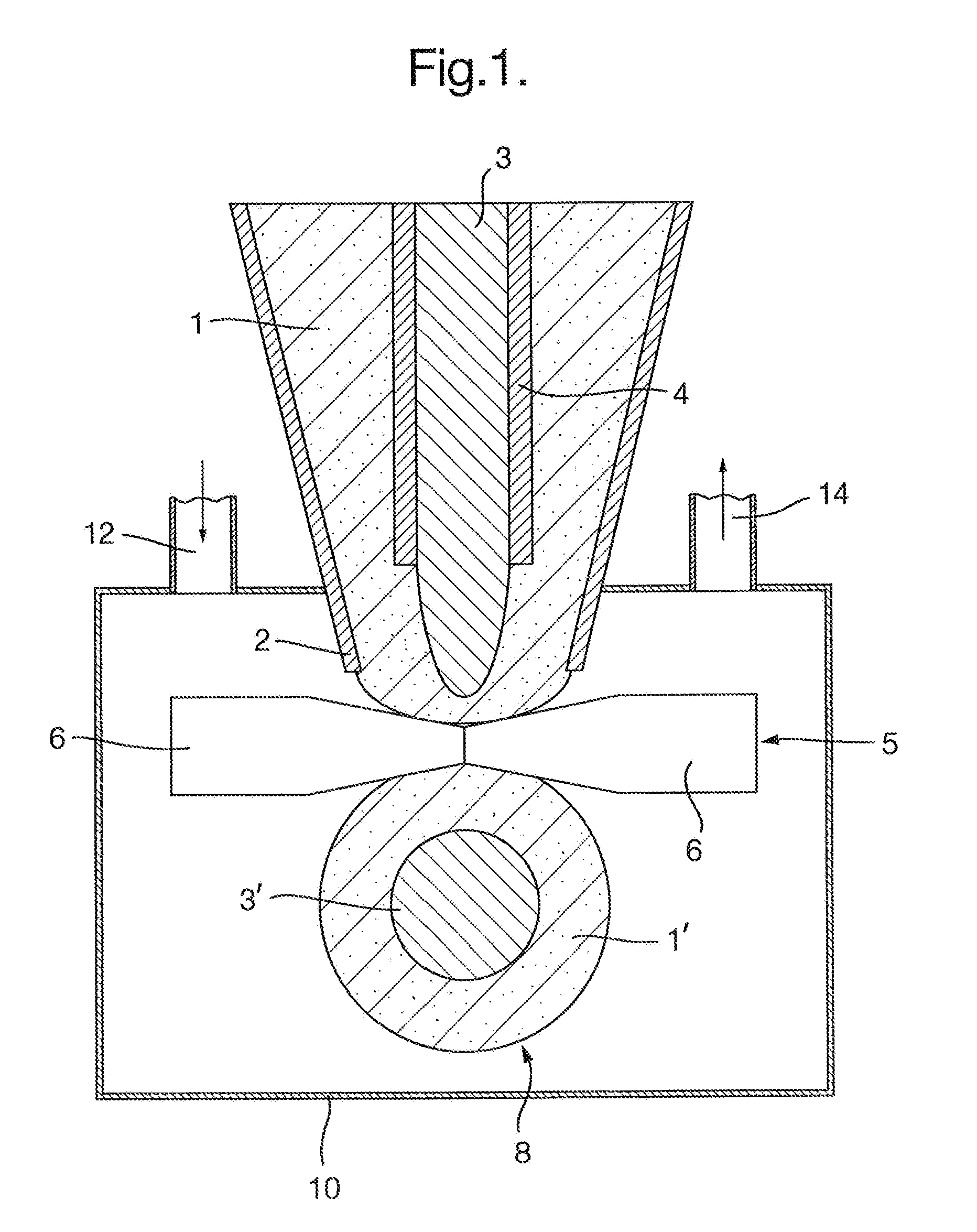

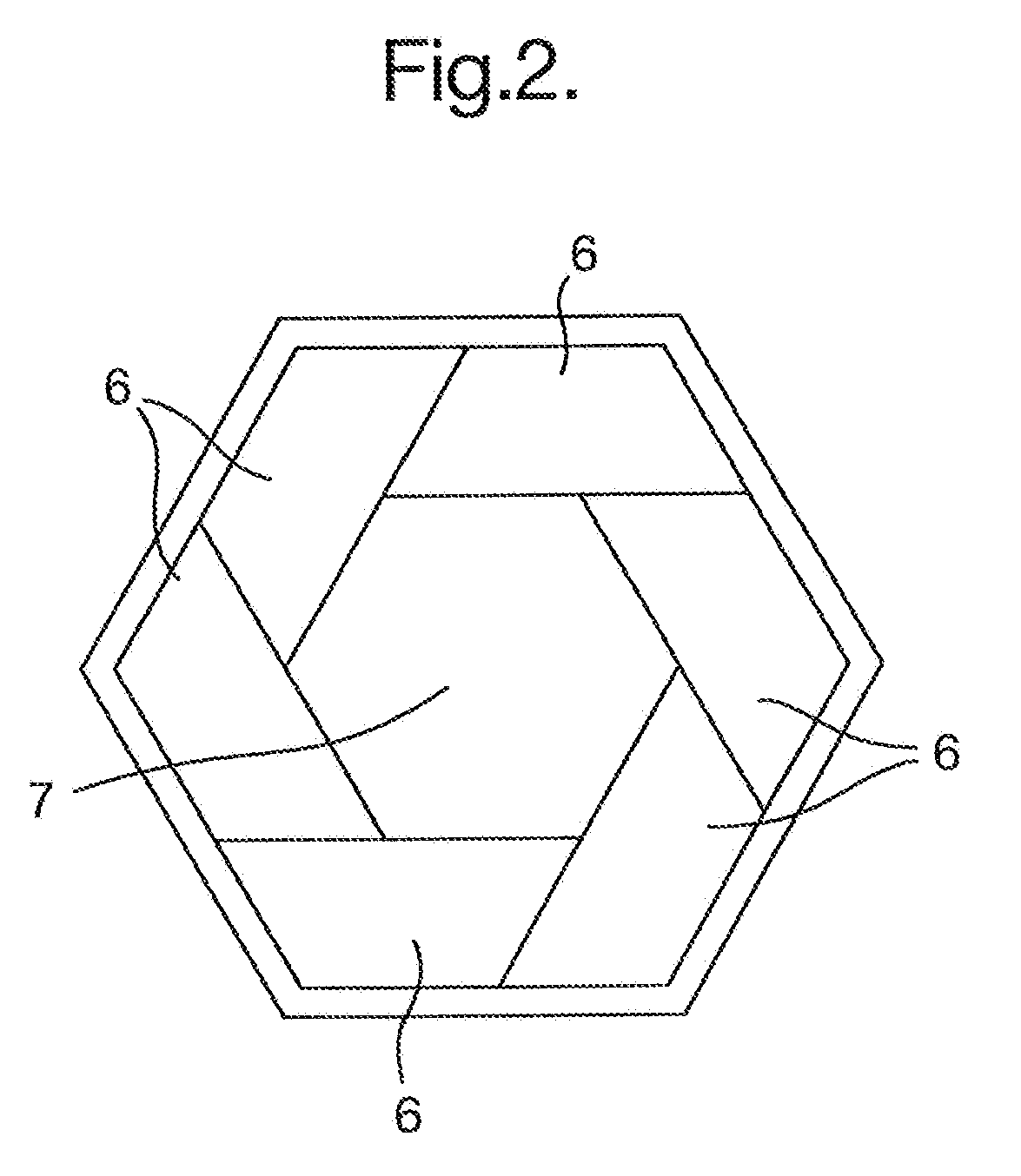

[0021]A standard ice cream mix was frozen to −6.5° C. and aerated to 100% overrun in an ice cream freezer. A standard chocolate sauce was cooled to −4° C. in an ice cream freezer but not aerated. The ice cream and sauce were fed to the outer and inner tubes of a co-extrusion nozzle, and after extrusion, the extrudate was cut and shaped by an iris cutter comprising six sliding blades.

[0022]The nozzle and cutter were located inside a refrigerated enclosed chamber with dimensions of height 50 mm, width 57 mm and depth 30 mm, constructed from polycarbonate sheets held in an aluminium frame. Air at approximately −7° C. was blown into the enclosed chamber from an air cooling unit (Zanotti, Model B GM 11702F) which produces 600 cubic metres of cold air per hour. The temperatures of the back of one cutter blade and of the cutter casing were measured using temperature probes. The temperature of the environment within the chamber was also measured. Temperatures were recorded with and without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com