Process and apparatus for removal of sour species from a natural gas stream

a technology of natural gas stream and process, applied in the direction of lighting and heating apparatus, separation processes, gaseous fuels, etc., can solve the problems of increased plant down time for maintenance and repair, increased operating and storage efficiency, complex and expensive implementation methods, etc., to enhance the removal of sour species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]Before the preferred embodiment of the present apparatus is described, it is understood that this invention is not limited to the particular materials described, as these may vary. It is also to be understood that the terminology used herein is for the purpose of describing the particular embodiment only, and is not intended to limit the scope of the present invention in any way. It must be noted that as used herein, the singular forms “a”, “an”, and “the” include plural reference unless the context clearly dictates otherwise. Unless defined otherwise, all technical and scientific terms used herein have the same meanings as commonly understood by one of ordinary skill in the art to which this invention belongs.

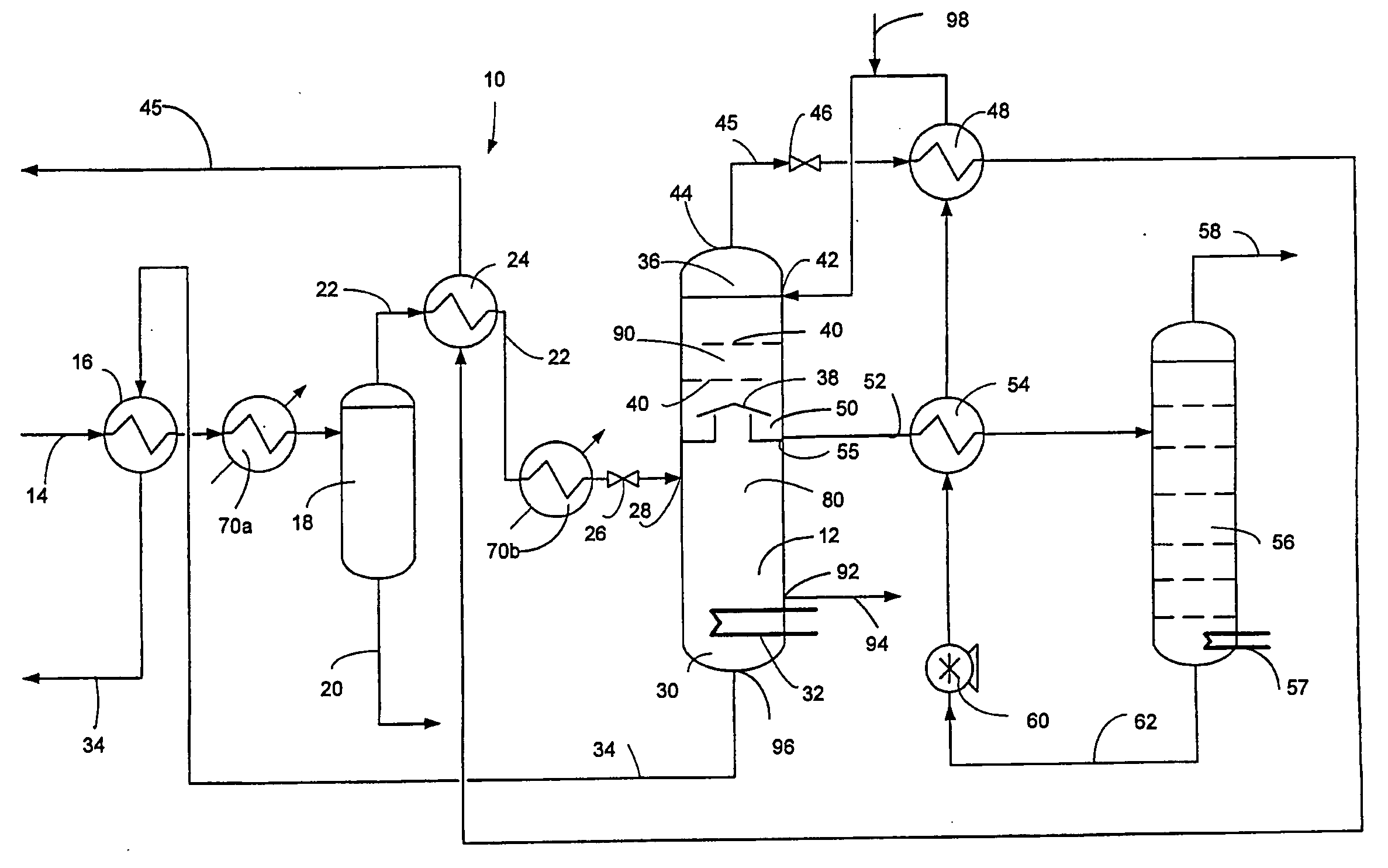

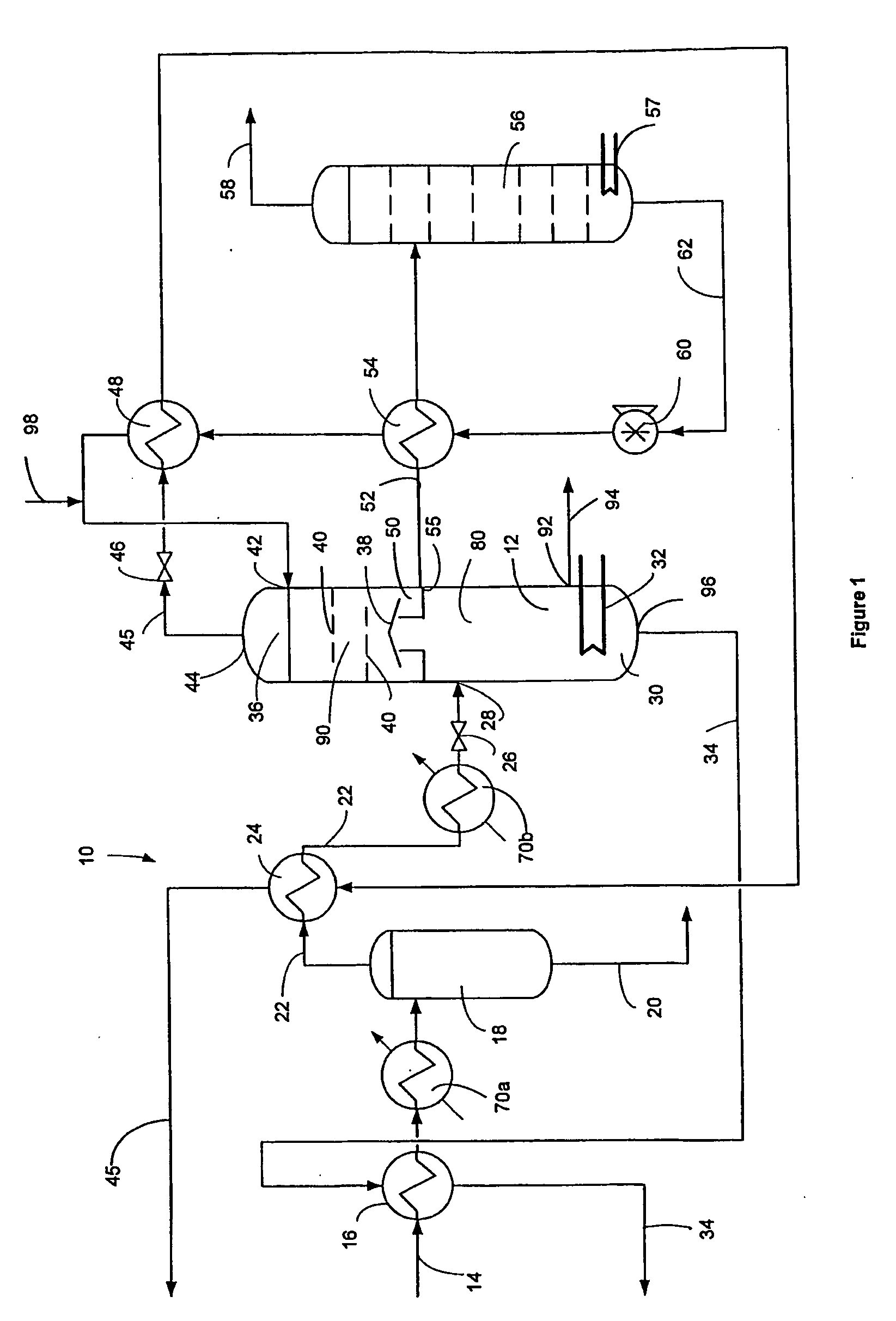

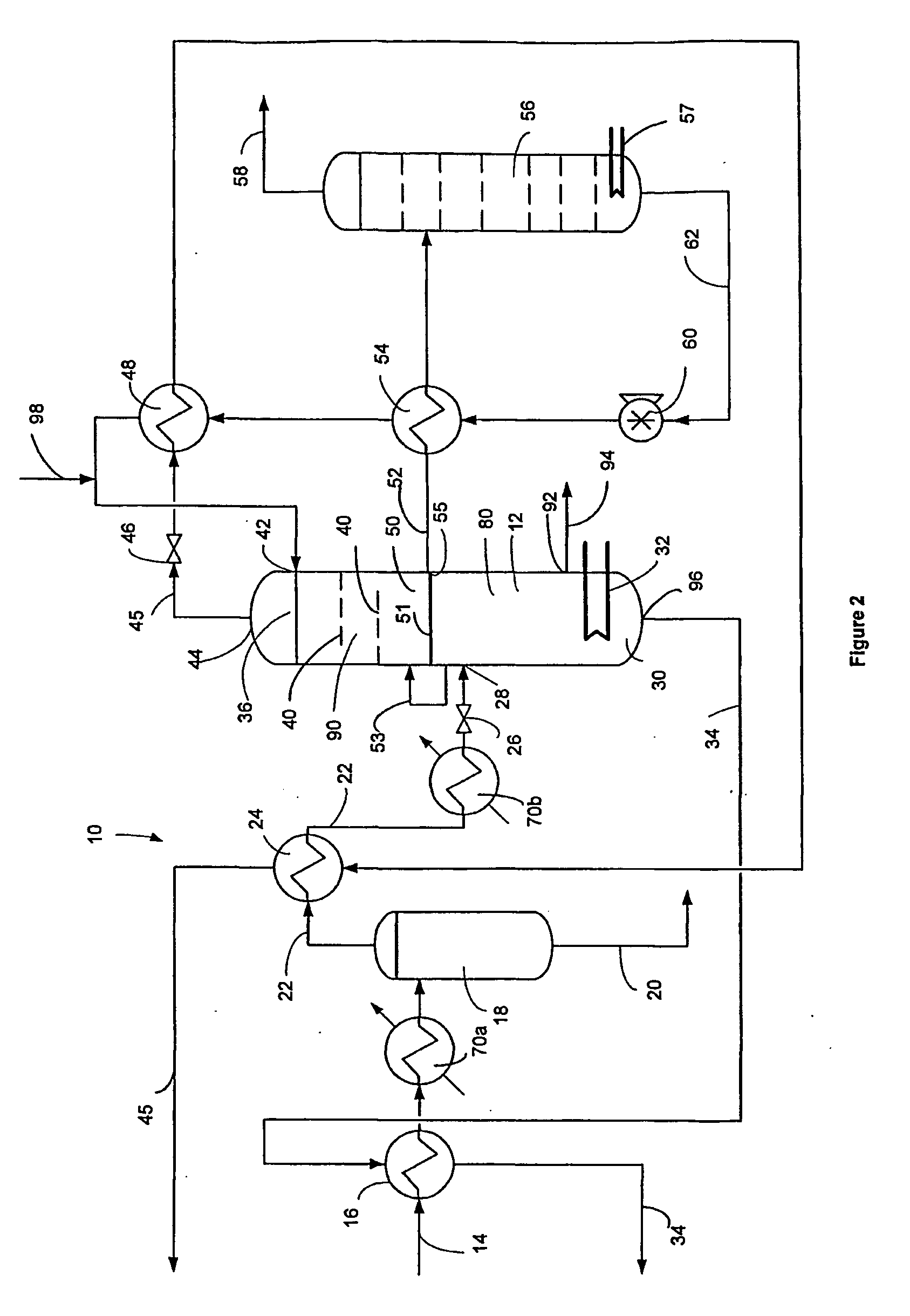

[0062]Referring to the figures, where like numerals refer to like features throughout, in accordance with various aspects of the present invention, there is shown an apparatus 10 for performing the process of the present invention. The apparatus 10 includes a vessel 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com