Use of iron ore agglomerates for acid gas removal

a technology of iron ore agglomerates and acid gas removal, which is applied in the direction of physical/chemical process catalysts, other chemical processes, separation processes, etc., can solve the problems of adverse environmental impact, prior art processes employing non-renewable sorbents that produce hazardous waste, and high cost of prior art processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The invention relates to a cost effective system and process for the removal of acid gas from fluid streams.

[0019]Hereinafter the term “fluid” includes but is not limited to matter in gaseous and / or liquid state. The term “fluid” may refer to any one or all of the following terms: oil, gas, water, liquids in an oil well, gases in an oil well, air and the like.

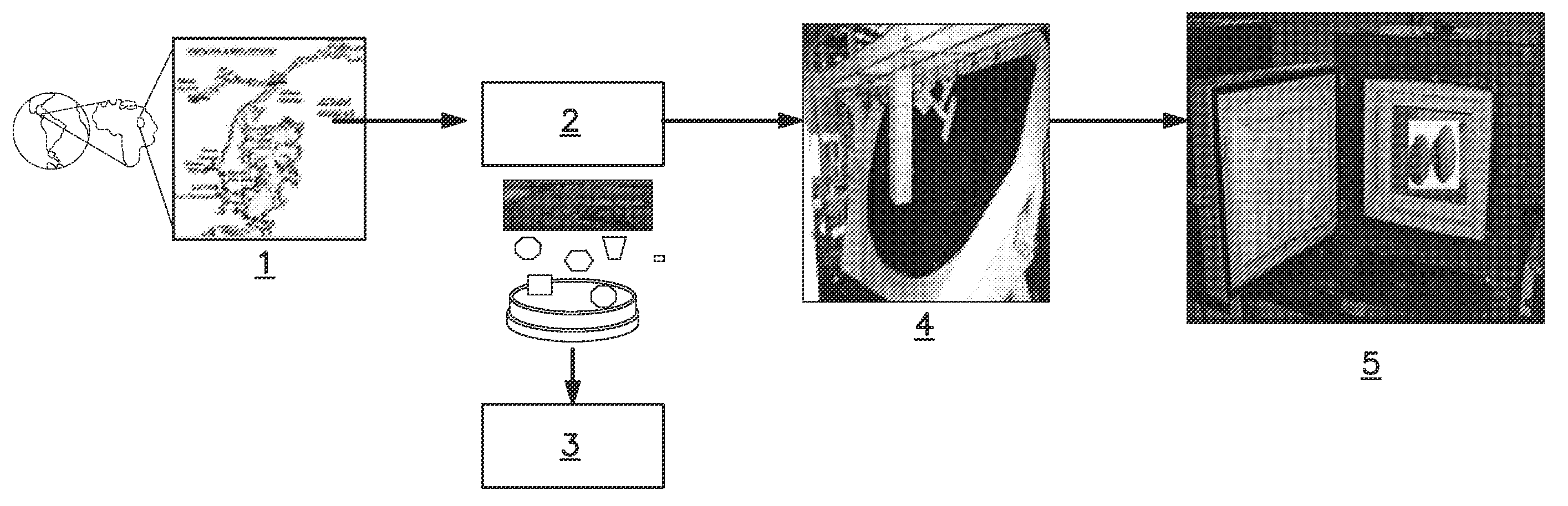

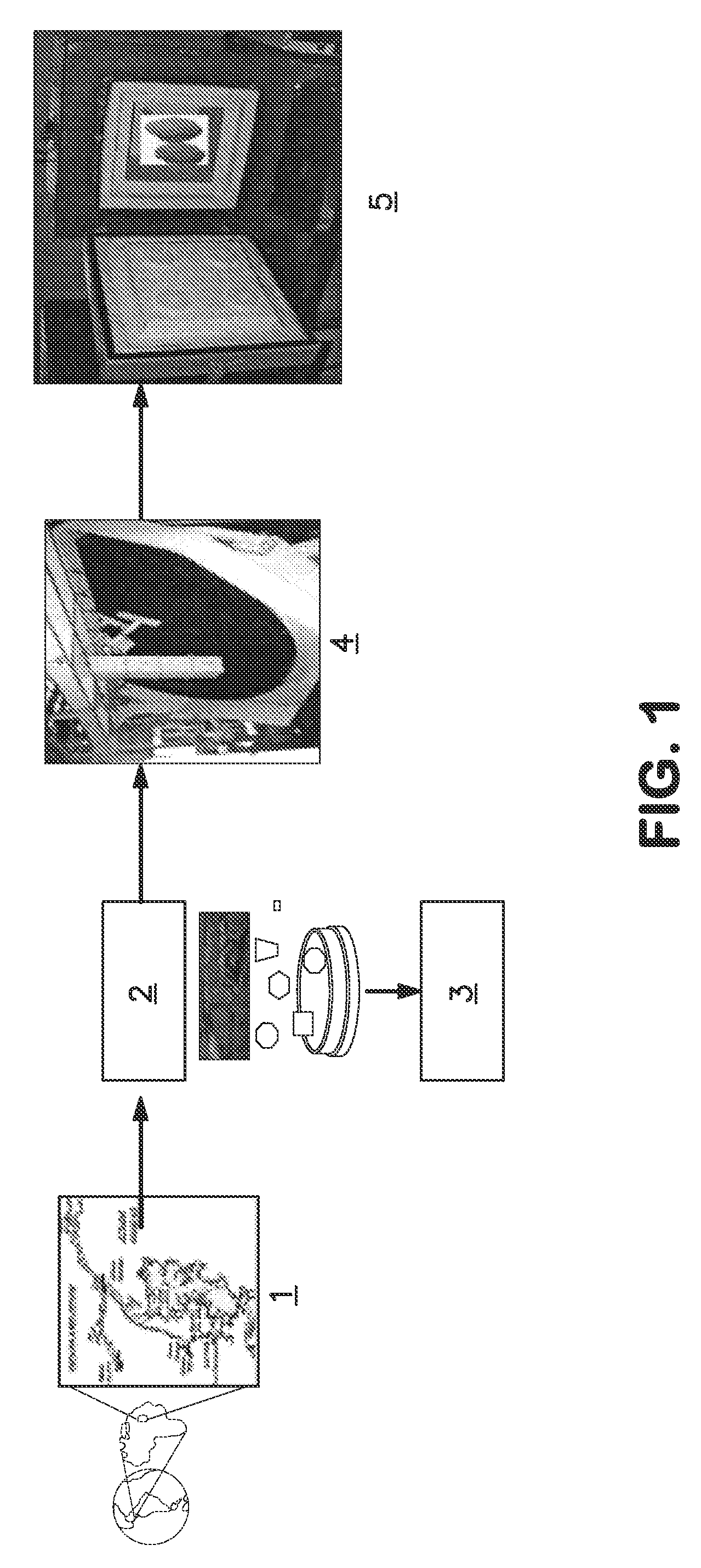

[0020]Referring now to FIG. 1 there is shown the general steps for manufacturing the renewable sorbent of the present invention. Raw materials are obtained in step 1, for example from a national market such as Venezuela, where raw material, such as iron mineral and an expansive clay, may be easily obtained.

[0021]After the raw materials are obtained 1 they are then dried at 100° C. for about 24 hours. After drying the raw materials are then mixed together into a composition before they are crushed and sifted in a milling process 2. The milling may be carried out under any procedure that is well known within the art. For ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com