Method for Processing Industrial and Domestic Wastes

a technology for industrial and domestic waste, applied in the field of chemical technology and equipment, can solve the problems of reducing the volume of gas, affecting the use of obtained gas in power generation cycle and for synthesis of, e.g., petrol, and reducing the thermal power of obtained gas and its chemical composition, so as to improve the discharge conditions of slag, increase the cost-effectiveness, and increase the quality and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The implementation of the invention and operation of the apparatus are described below.

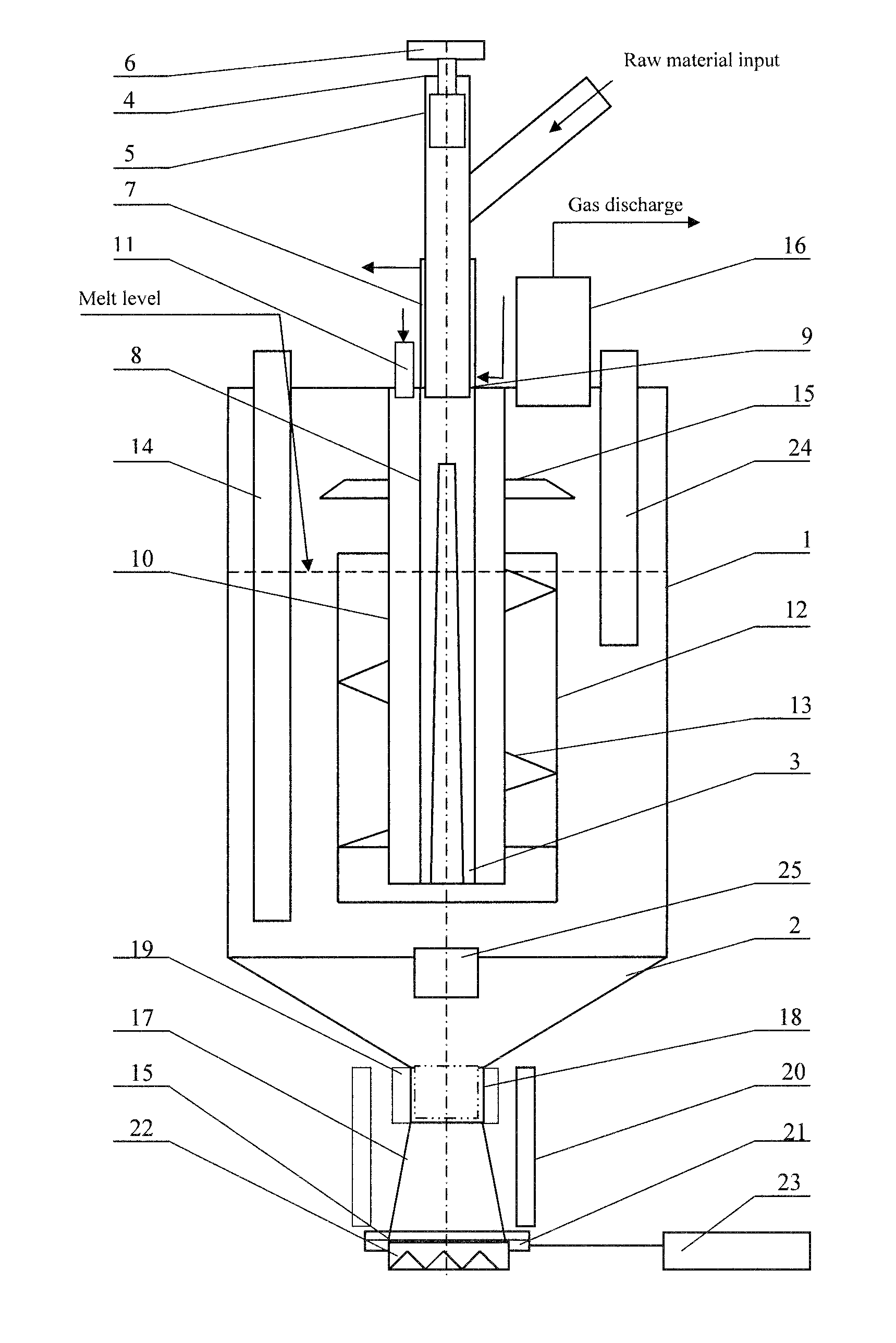

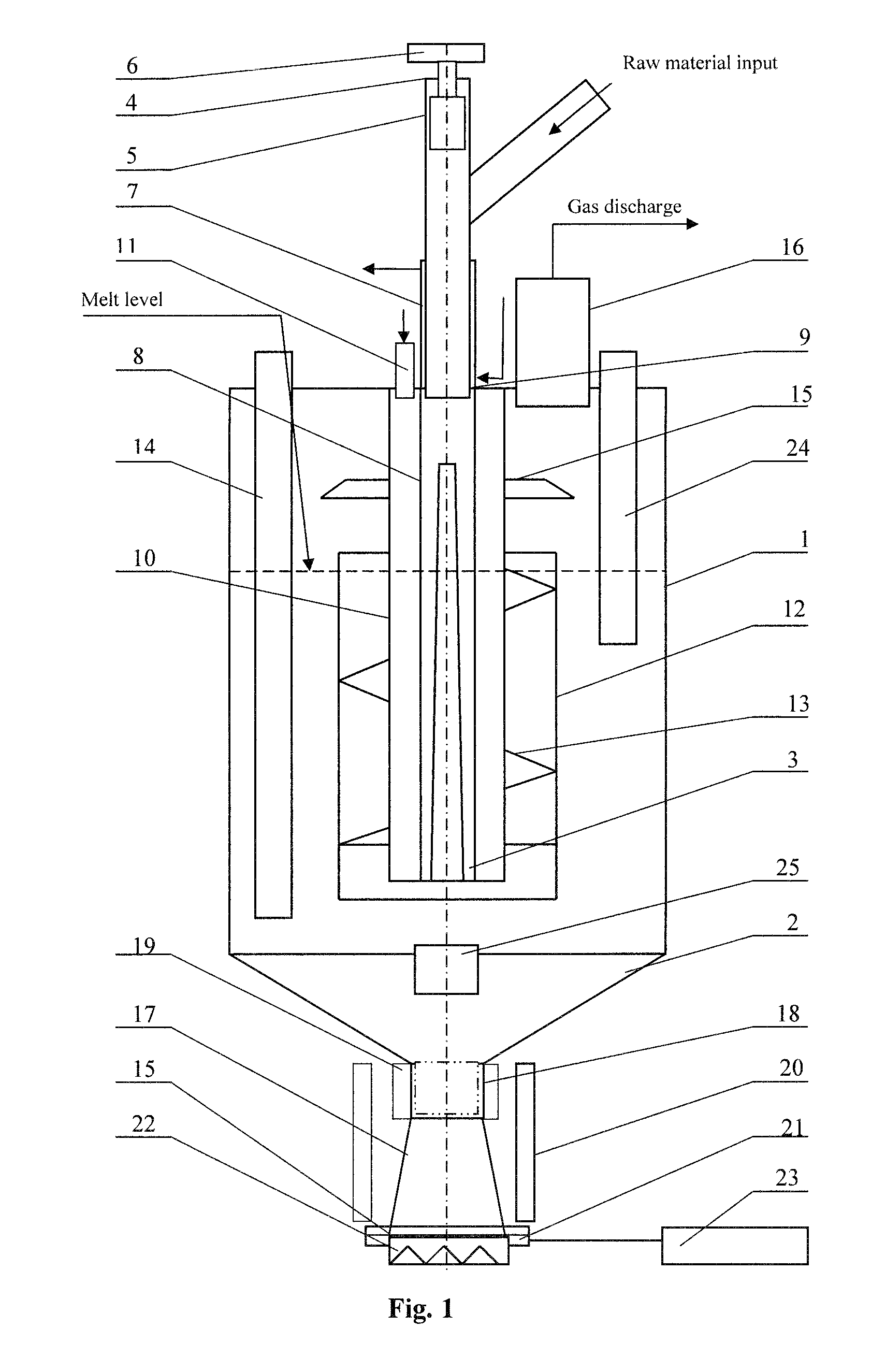

[0017]The reactor for industrial and household waste processing has cylindrical vessel 1 with conical bottom 2. Device for waste loading 4 is installed in direction of the vessel 1, at that the lower end of the waste loading device 4 is located under reactor's cover. Vertical loading channel 3 of the waste loading device 4 is equipped with the piston 5 with the drive 6 of reciprocal motion and cooler 7. The lower open outlet end of the loading device pipe 4 is located at level of the lower end of the cooler 7. The pipe of the loading device 4 has an opening for waste supply into the loading device pipe 4 under the upper position of the piston 5. The loading device pipe 4 is turned into the reactor pipe 8 in such a way that the upper annular clearance between the pipe of the loading device 4 and reactor pipe 8 is blocked with the bridge 9.

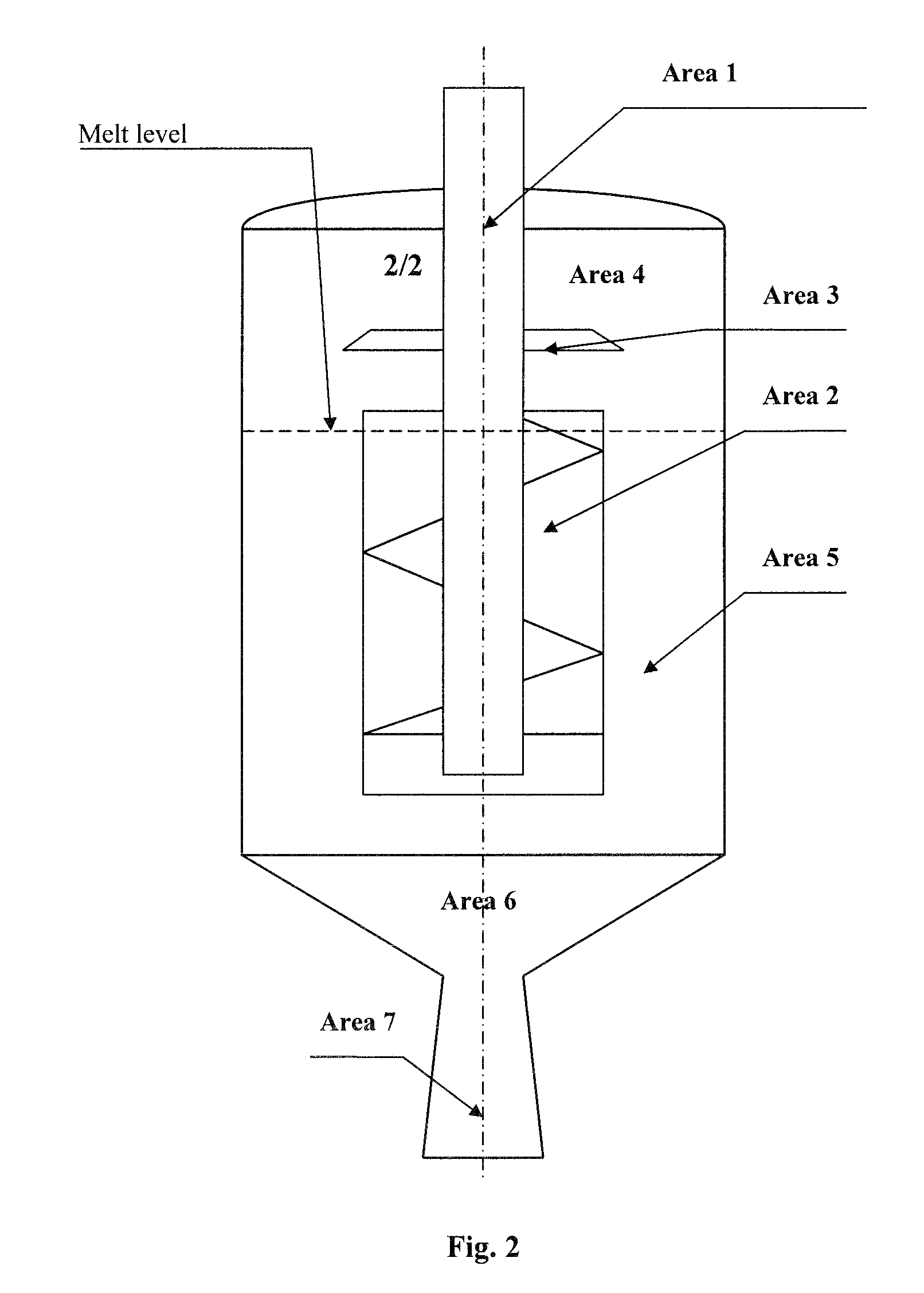

[0018]Damper chamber 10 is located coaxially with reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com