Optical System and Assembly Method

a technology of optical system and assembly method, which is applied in the direction of manufacturing tools, furniture parts, instruments, etc., can solve the problems of high cost of ownership for theater owners, high cost of electricity, and high cost of image projecting on the screen, and achieve the effect of long operation li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

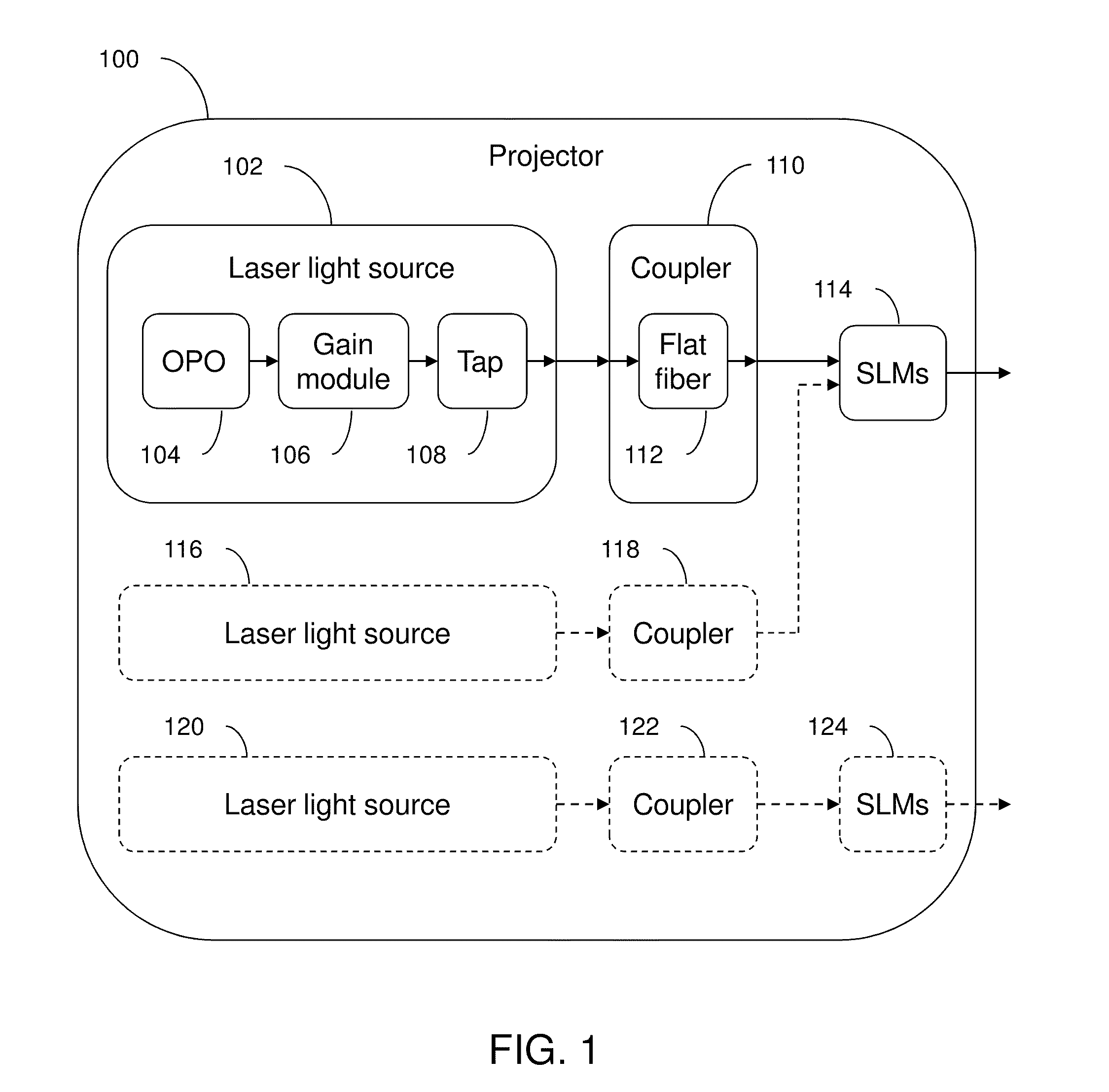

[0126]FIG. 1 is a block diagram of optical system 100 which has a number of novel parts that will be explained in the following description. First laser light source 102 may include OPO 104, laser gain module 106, and optical tap 108. Light is generated in OPO 104, passes through gain module 106, then through tap 108. The light then passes through first coupler 110 which includes flat-sided fiber 112, and then is processed by first SLMs 114. The light is then projected out of the optical system.

[0127]Second laser light source 116 may optionally be included for stereoscopic optical systems. The light from second laser light source 116 passes through second coupler 118 and then through first SLMs 114. The light is then projected out of the optical system. Alternatively, third laser light source 120 may optionally be included for stereoscopic optical systems. The light from third laser light source 120 passes through third coupler 122 and then through second SLMs 124. The light is then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com