Method for the uninterrupted operation of a gas liquefaction system

a gas liquefaction and continuous operation technology, applied in the direction of solidification, non-positive displacement fluid engines, lighting and heating apparatus, etc., can solve the problems of difficult startup or restart of single-shaft gas turbines, failure of the lng production process, and production downtime, so as to reduce the emission of greenhouse gases, reduce the load of compressors, and increase the thermal efficiency of plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

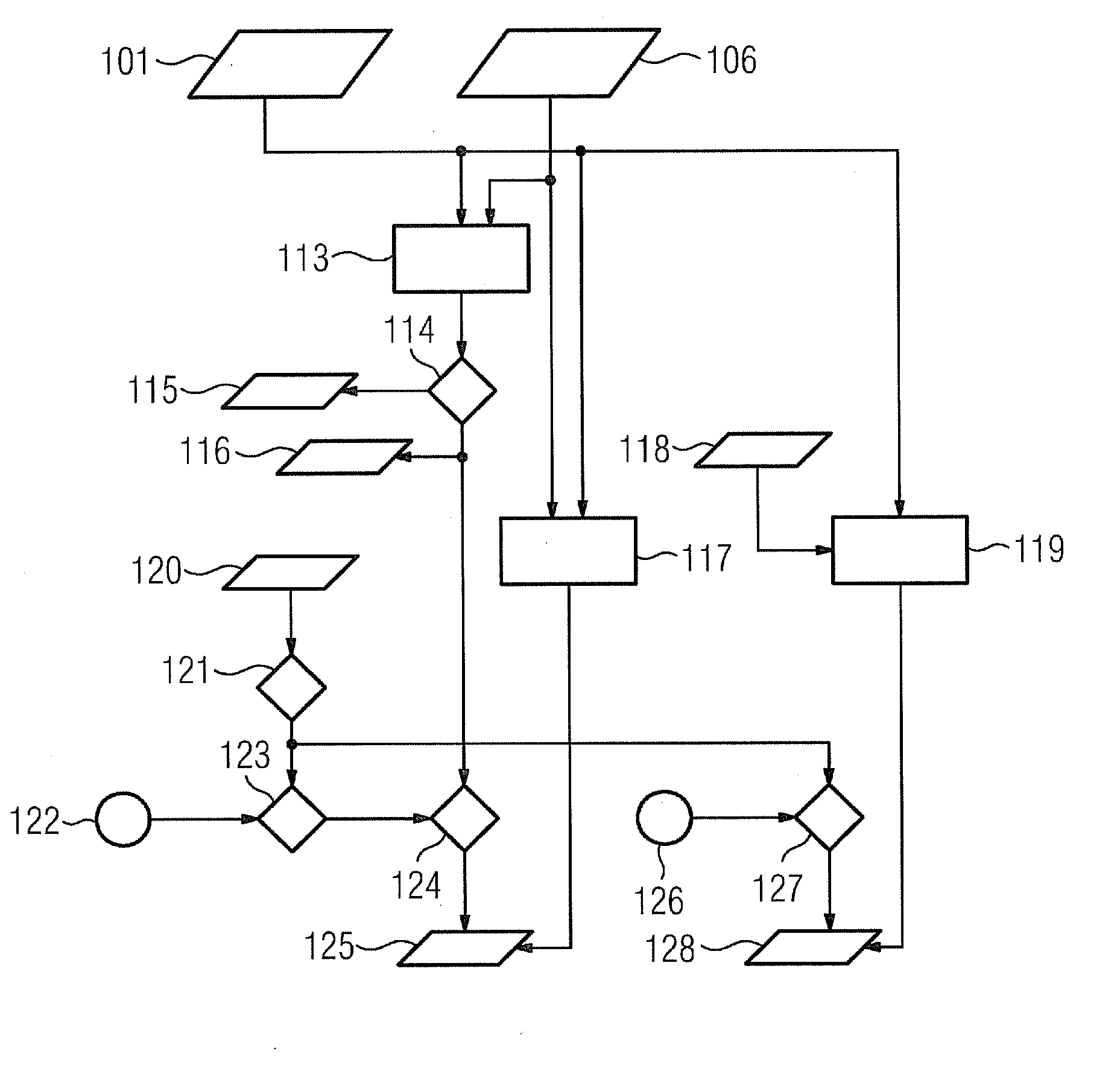

[0035]FIG. 1 shows an integrated solution for a gas liquefaction plant 1 with a stand-alone power plant 23 as the power generation module 2, a transfer module 3 for distributing the power and a refrigerant compression module 4. A control system 5 is connected to the power generation module 2, the transmission module 3 and the refrigerant compression module 4.

[0036]The power generation module 2 incorporates three turbine sets 6, each with a turbine 10 and a generator 12, which are connected via a shaft 11. However, the power generation module 2 can also incorporate less than three or more than three turbine sets 6.

[0037]The turbine sets 6 are in each case connected via an electrical transformer 13 to the power plant busbar 15 of the transmission module 3, which makes the electrical power available to the motors in the refrigerant compression module 4 and / or other consumers 26.

[0038]In the refrigerant compression module 4, the variable-speed electric motors 8 of the refrigerant compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com