Load-lock apparatus and substrate cooling method

a technology of substrate cooling and load-locking, which is applied in the direction of lighting and heating apparatus, vacuum evaporation coating, coating, etc., can solve the problems of reducing cooling efficiency, oxidizing the wafer, and melting of the receiving vessel generally made of resin, so as to prevent the deformation of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

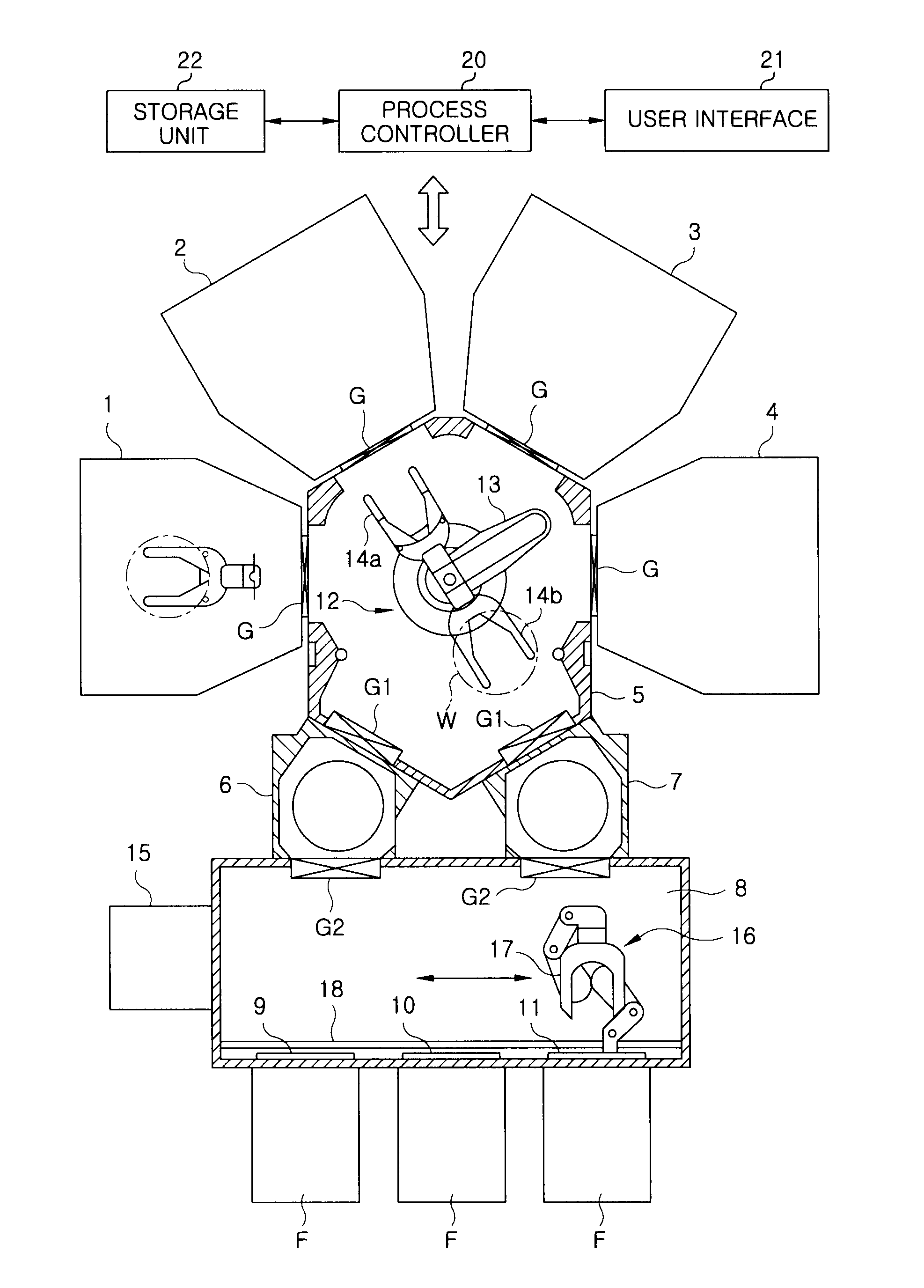

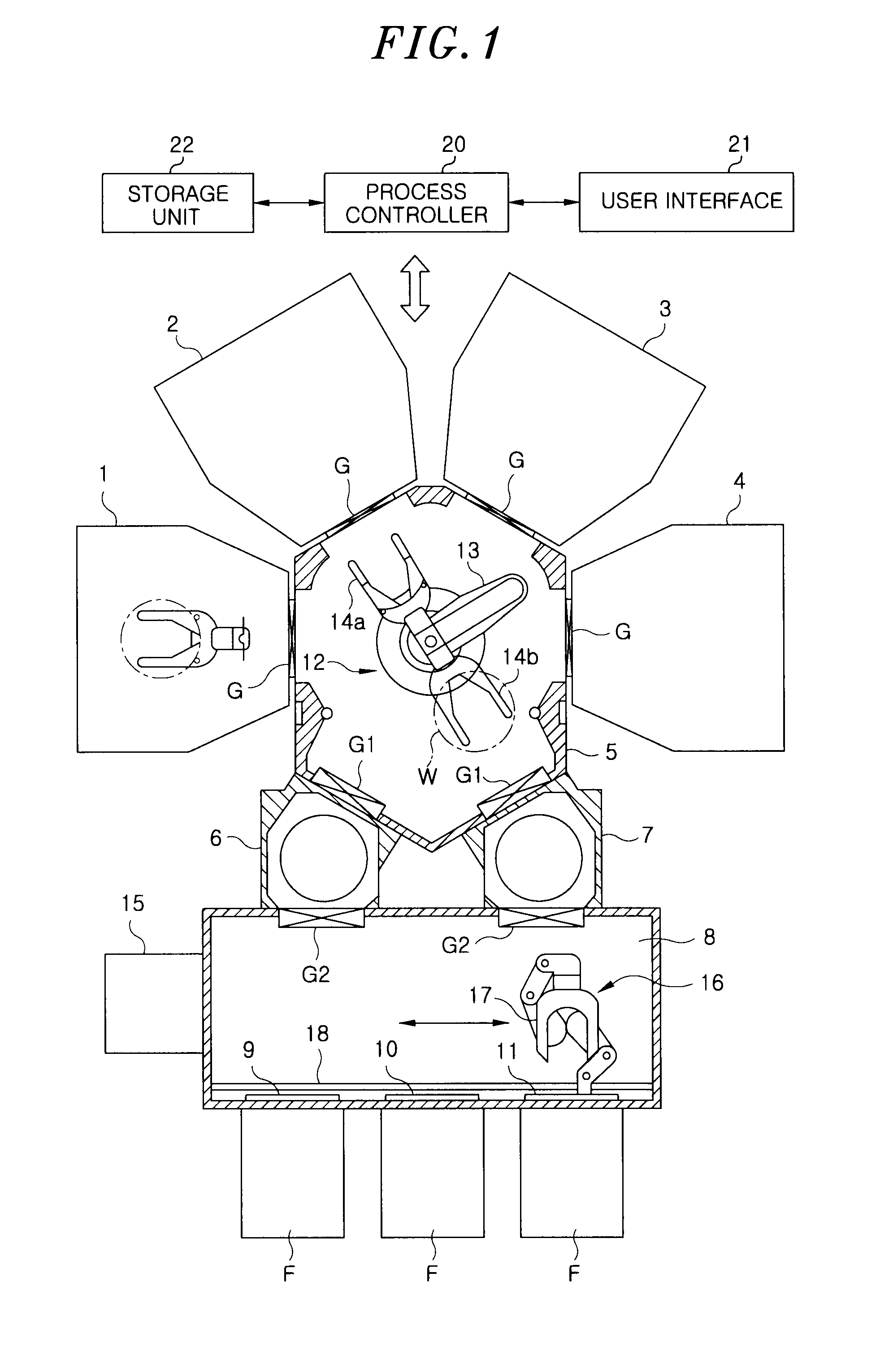

[0027]Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 is a transversal cross sectional view schematically showing a multi-chamber type vacuum processing system including a load-lock apparatus in accordance with an embodiment of the present invention.

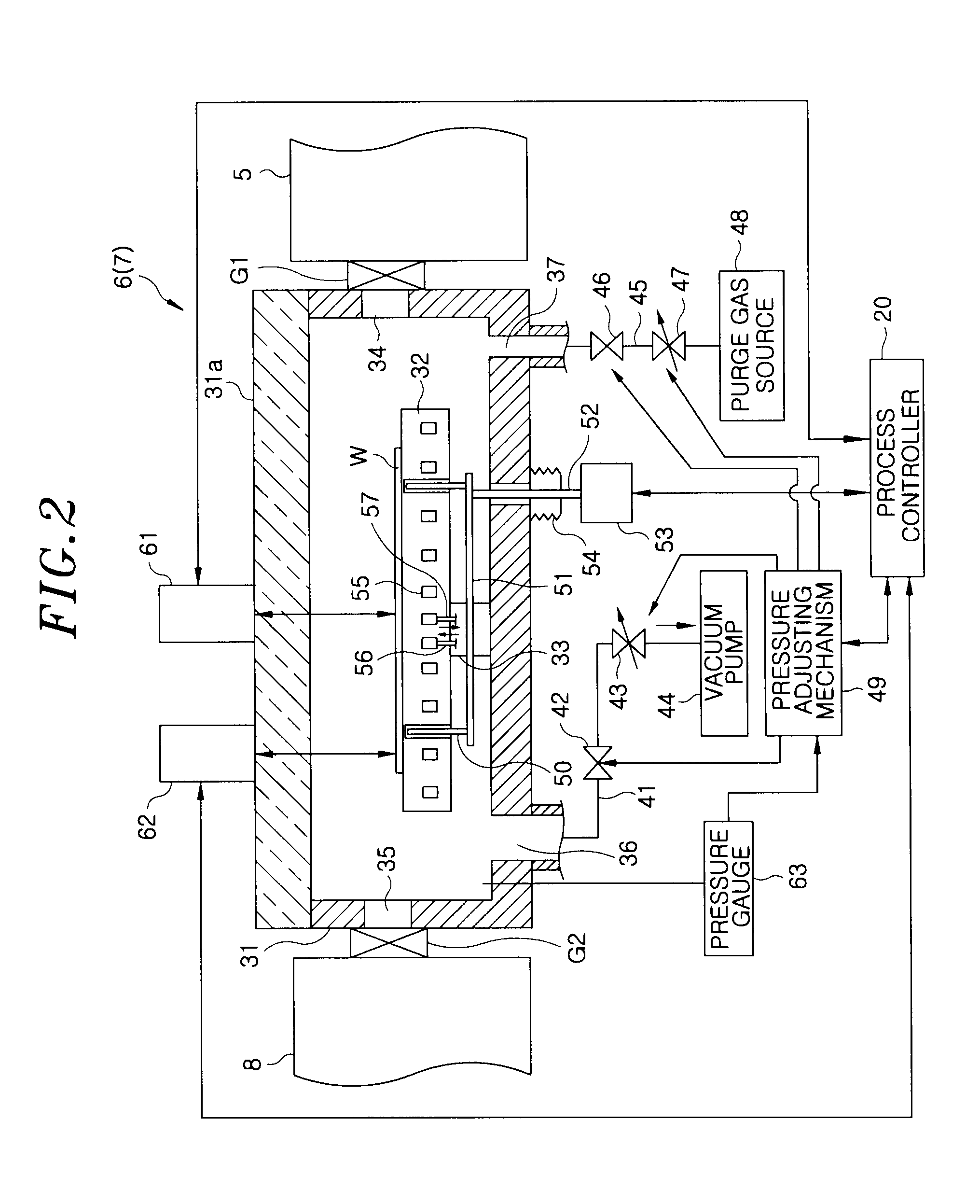

[0028]The vacuum processing system includes four vacuum processing units 1, 2, 3 and 4, each unit performing a high temperature process such as a film forming process in a vacuum. The vacuum processing units 1, 2, 3 and 4 are connected to four sides of a hexagonal transfer chamber 5, respectively. Further, load-lock apparatus 6 and 7 in accordance with the embodiment of the present invention are connected to the other two sides of the transfer chamber 5, respectively. A loading / unloading chamber 8 is connected to the load-lock apparatus 6 and 7 to be opposite to the transfer chamber 5. Ports 9, 10 and 11, to which three Front Opening Unified Pods (FOUPs) F capable of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Deformation enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com