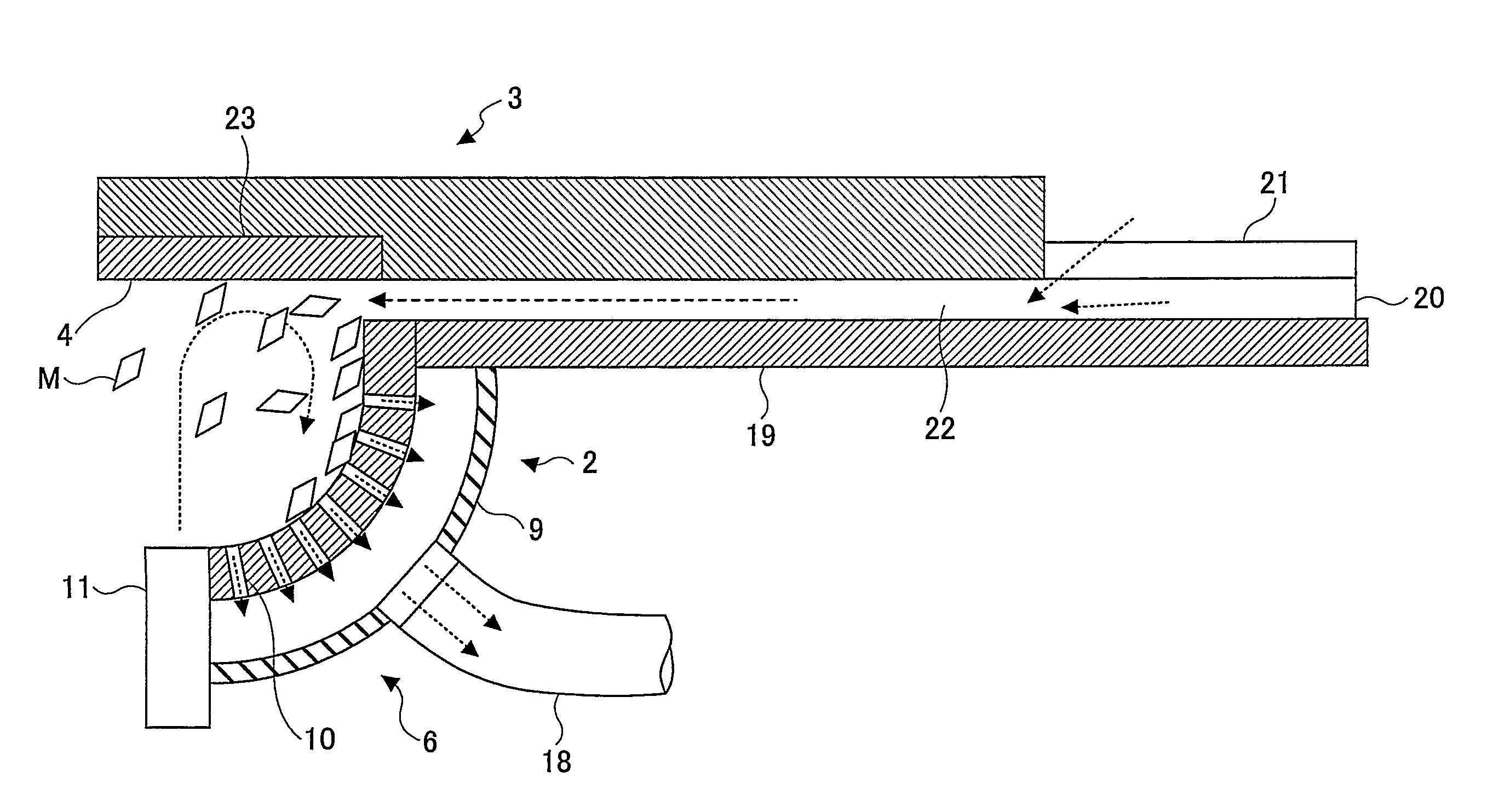

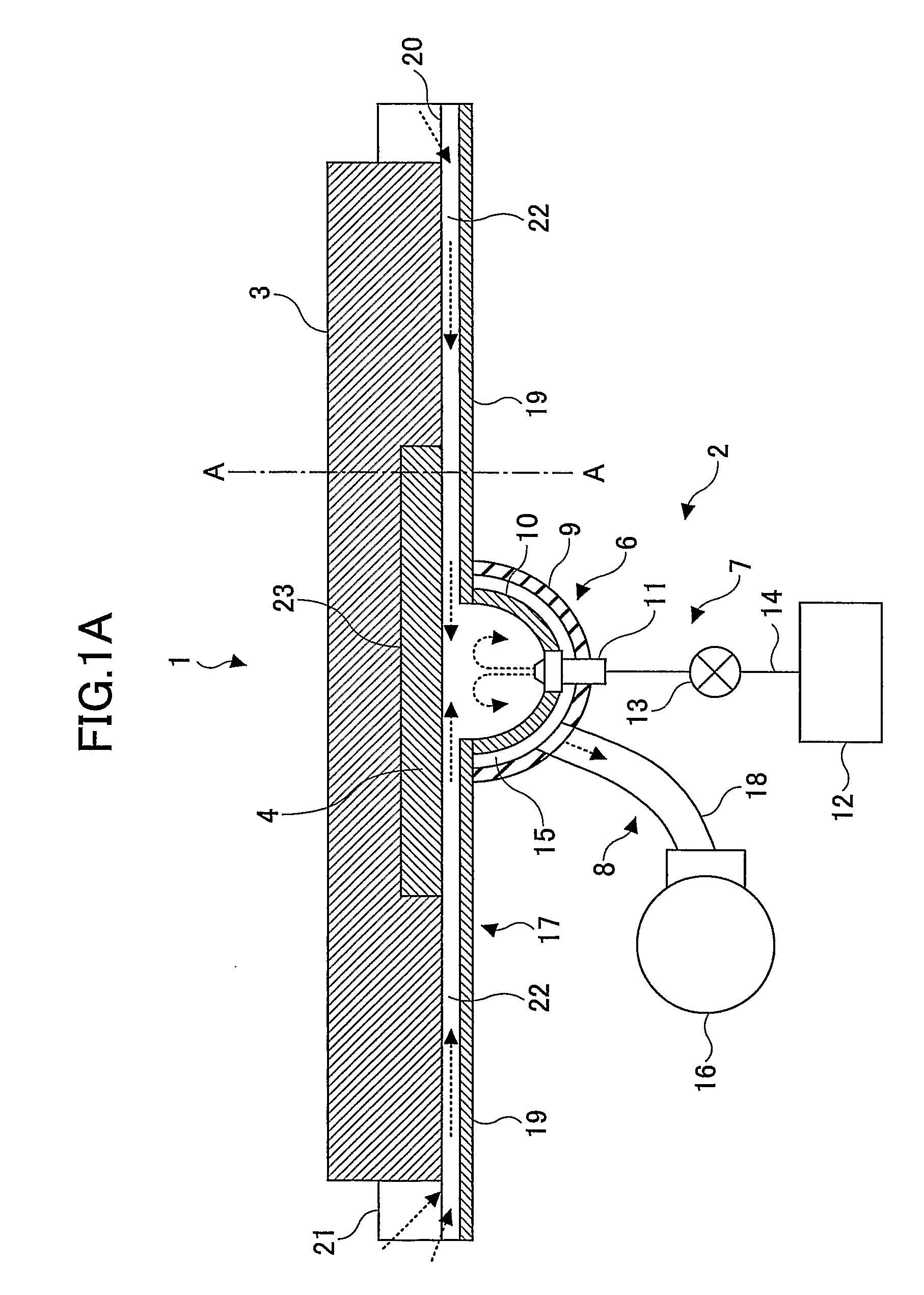

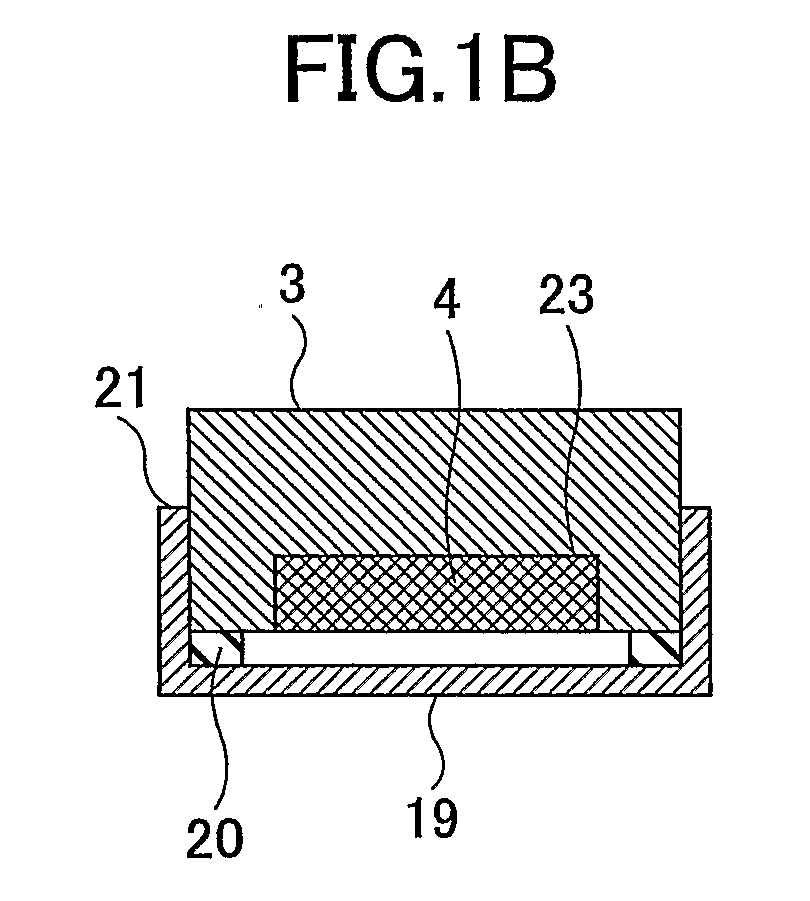

Cleaning device and cleaning method

a cleaning device and cleaning method technology, applied in the direction of cleaning process and apparatus, chemical apparatus and processes, etc., can solve the problems of inability to use removers repeatedly, inconvenient cleaning methods, and inability to achieve high-speed cleaning, easy acceleration, and low air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0173]In example 1, a fusing roller of imagio Neo 300 (monochrome copier) was used as an object to be cleaned.

[0174]The pencil hardness of fluoroplastic forming the release layer of the fusing roller was about “F”.

[0175]Each object was cleaned for two minutes using arrays of air nozzles SL-920A of Silvent to jet compressed air and the pressure of the compressed air was maintained at 0.5 MPa.

[0176]In example 1, the following types of cleaning media M were used:

[0177](Example 1-1) polyethylene films (pencil hardness 6B or lower) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0178](Example 1-2) PET films (pencil hardness H) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0179](Example 1-3) acrylic resin films (pencil hardness 2H) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0180](Example 1-4) flakes of SUS304 (pencil hardness 9H or higher) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0181]As comparative examples, the object was cleaned by ...

example 2

[0191]Each object was cleaned for two minutes using arrays of air nozzles SL-920A of Silvent to jet compressed air and the pressure of the compressed air was maintained at 0.5 MPa.

[0192]In example 2, the cleaning media were repeatedly used without replacing them for multiple objects and the cleaning quality was evaluated in association with the number of objects processed.

[0193]In example 2, the following types of cleaning media M were used.

[0194](Example 2-1) polyethylene films (pencil hardness 6B or lower) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0195](Example 2-2) PET films (pencil hardness H) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0196](Example 2-3) acrylic resin films (pencil hardness 2H) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0197](Example 2-4) flakes of SUS304 (pencil hardness 9H or higher) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0198]Cleaning results are shown in table 2 below. Meanings of symbols used ...

example 3

[0200]In examples 3 and 4, a photosensitive layer (polycarbonate binder resin with pencil hardness F) of an organic photoreceptor (OPC) drum used in an electrophotographic device such as a copier or a laser printer was used as a deposit to be removed. However, the present invention may also be applied to a cleaning device for removing any other type of film-like deposit.

[0201]The type of cleaning media and the speed and flow rate of the air flow are appropriately determined according to the characteristics of the film-like deposit and the object to be cleaned.

[0202]Each object was cleaned for two minutes using arrays of air nozzles SL-920A of Silvent to jet compressed air and the pressure of the compressed air was maintained at 0.5 MPa.

[0203]In example 3, the following types of cleaning media M were used.

[0204](Example 3-1) polyethylene films (pencil hardness 6B or lower) with a thickness of 100 μm and dimensions of 5 mm by 5 mm

[0205](Example 3-2) PET films (pencil hardness H) with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com