Photobioreactor

a photobioreactor and bioreactor technology, applied in the field of wastewater treatment systems and methods, can solve the problems of unprecedented environmental problems, high fish kill rate, ocean floor plant kill rate, etc., and achieve the effects of high density, high density, and high cost-effective bioremediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

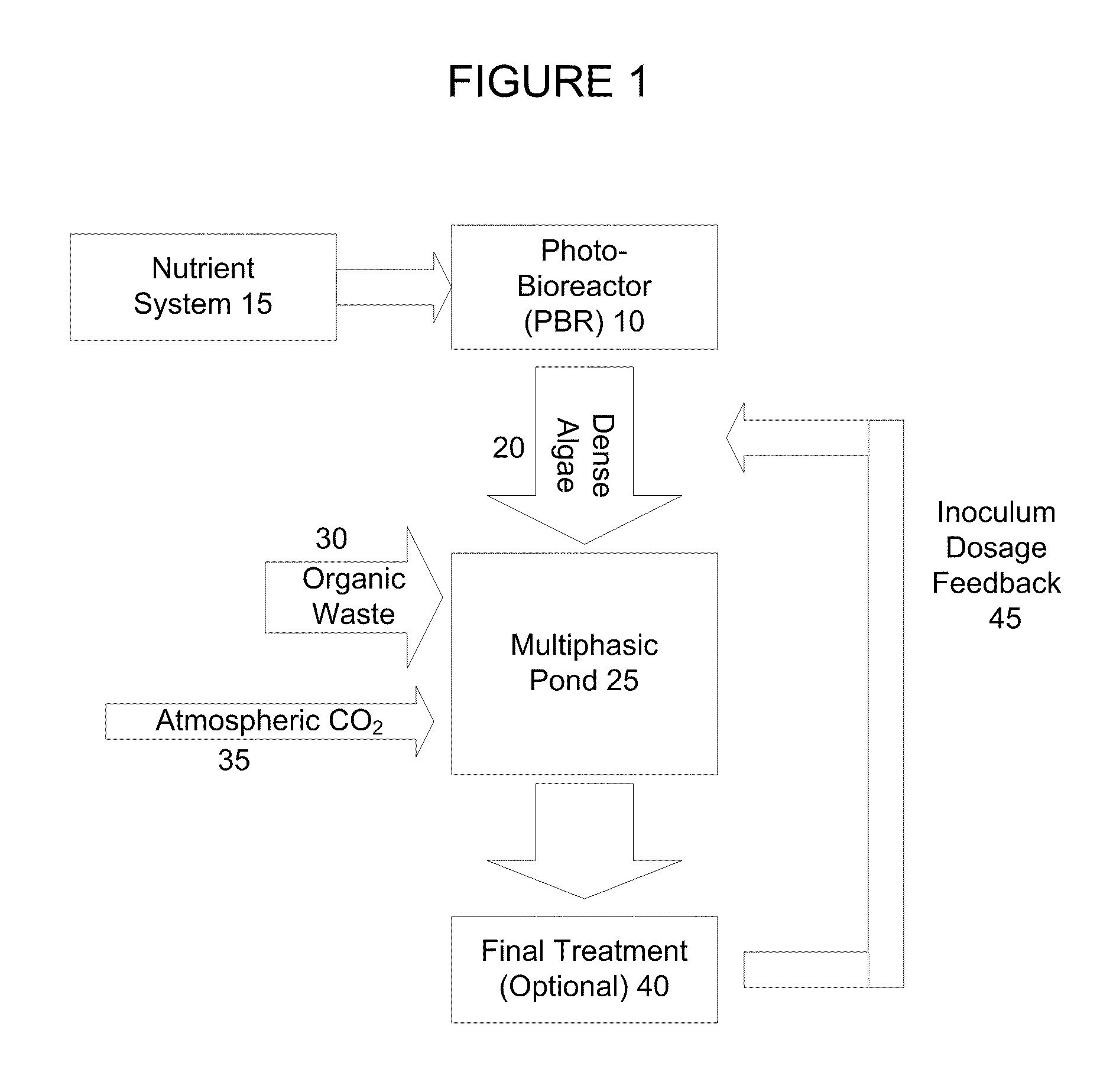

[0029]Referring first to FIG. 1, a bioremediation system in accordance with one aspect of the invention comprises a photobioreactor or PBR 10, described in greater detail hereinafter, which receives a nutrient stream from a nutrient system 15. The PBR provides an optimized environment for the growth of highly concentrated algae. The algae from the PBR 10 is supplied via a conduit 20 to a wastewater pond or lagoon 25, which, in some but not necessarily all embodiments, is a multiphasic pond as discussed in connection with FIG. 5. The pond or lagoon 25 receives organic waste 30, and, in many embodiments, can also receive atmospheric CO2 as indicated at 35.

[0030]The wastewater pond or lagoon 25, which can cover less than an acre to tens or hundreds of acres and could even be an open water area such as a lake or bay given sufficiently large algae supplies, comprises in some embodiments a relatively shallow pond having at least one remediation strata and, in the case of multiphasic ponds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com